Die Casting Services In Tulsa

At Frigate Die Casting Services, using the latest technology enables us to achieve Six Sigma-grade process control with minimal variation and high repeatability. We are proud to form partnerships with our customers, working closely to reduce part costs through strategic casting designs while maintaining superior quality.

Start A New Quote

Get Your Parts Manufactured inINDIA

Our Clients

What We Do

Our Casting Offerings

Partner with Frigate Engineering and unlock new technical expertise for your B2B manufacturing projects.

Our Business Verticals

Automotive

Construction

Healthcare

Energy Sector

Electronic

Defense

Household

Mining

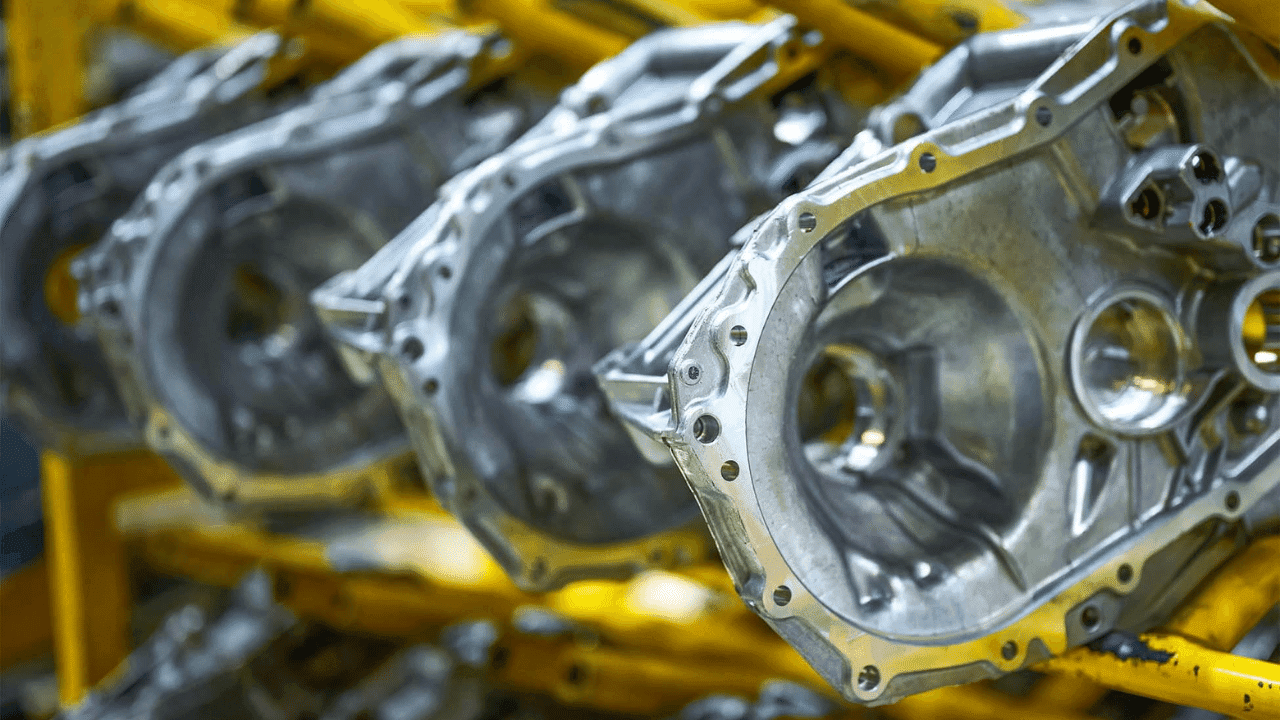

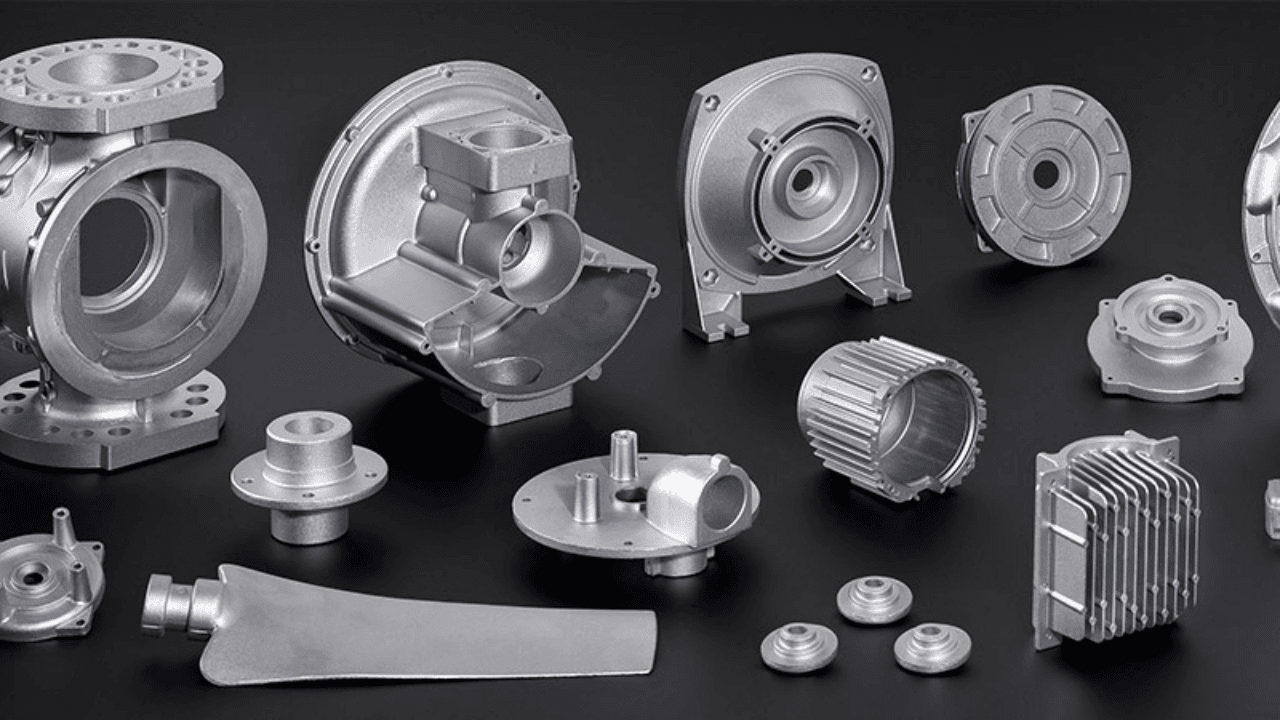

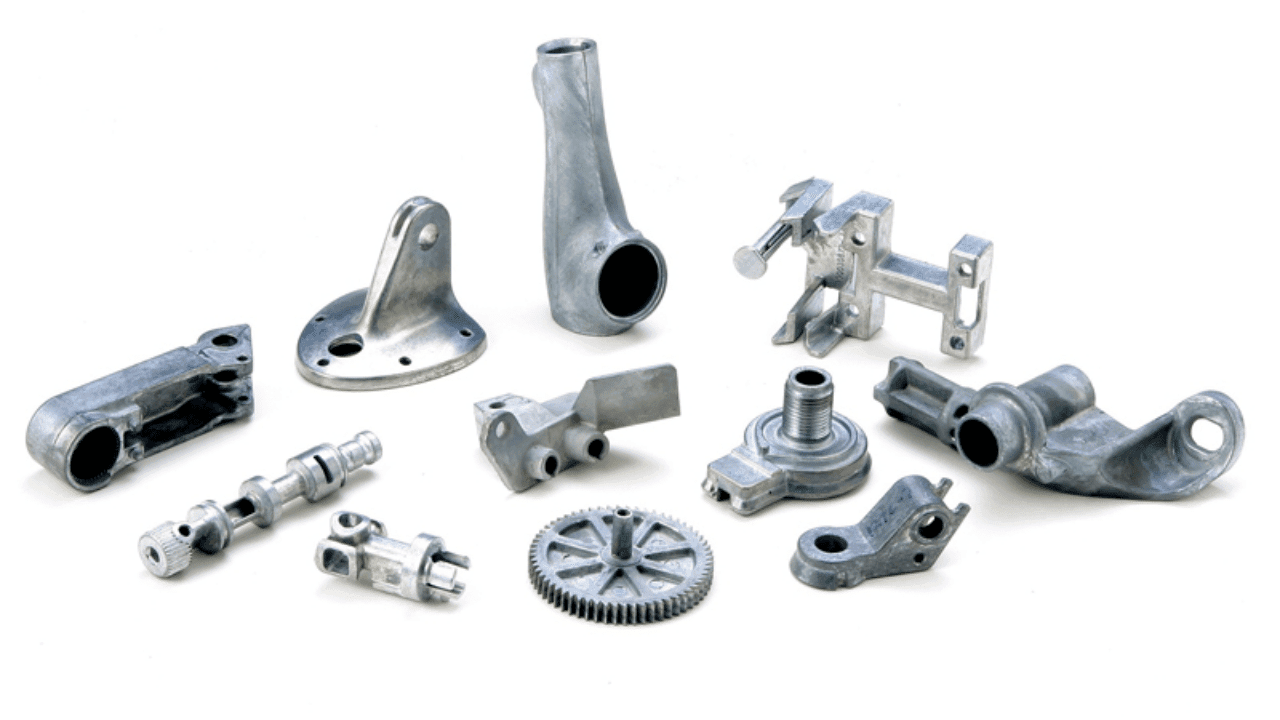

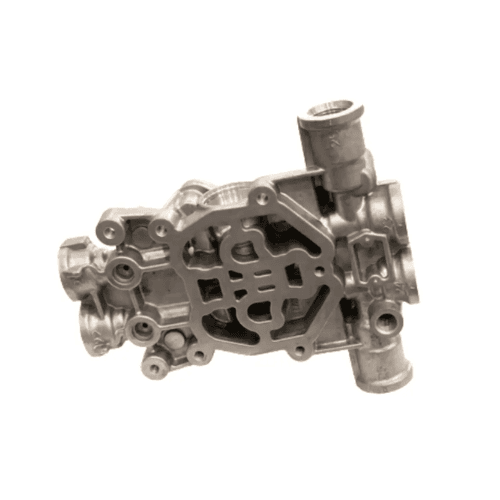

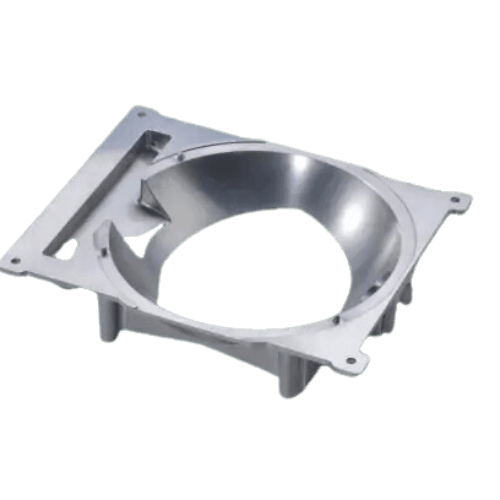

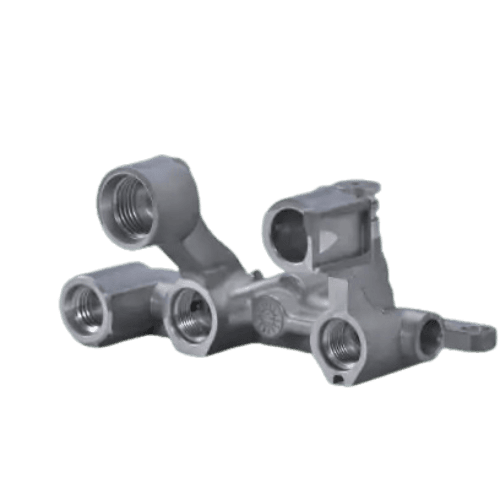

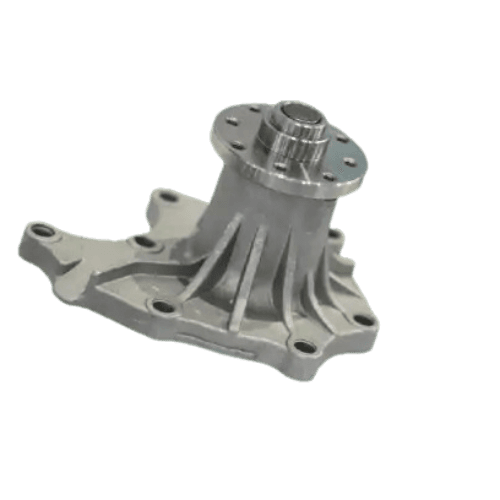

High-quality Die Casting for Your Custom Requirements

We specialize in delivering high-quality die-casting solutions tailored to your specific needs. Our expertise lies in producing parts with exceptional detail, dimensional accuracy, and a flawless finish. Whether you need small or large volumes, our experienced team ensures that your parts meet the highest standards of quality and precision.

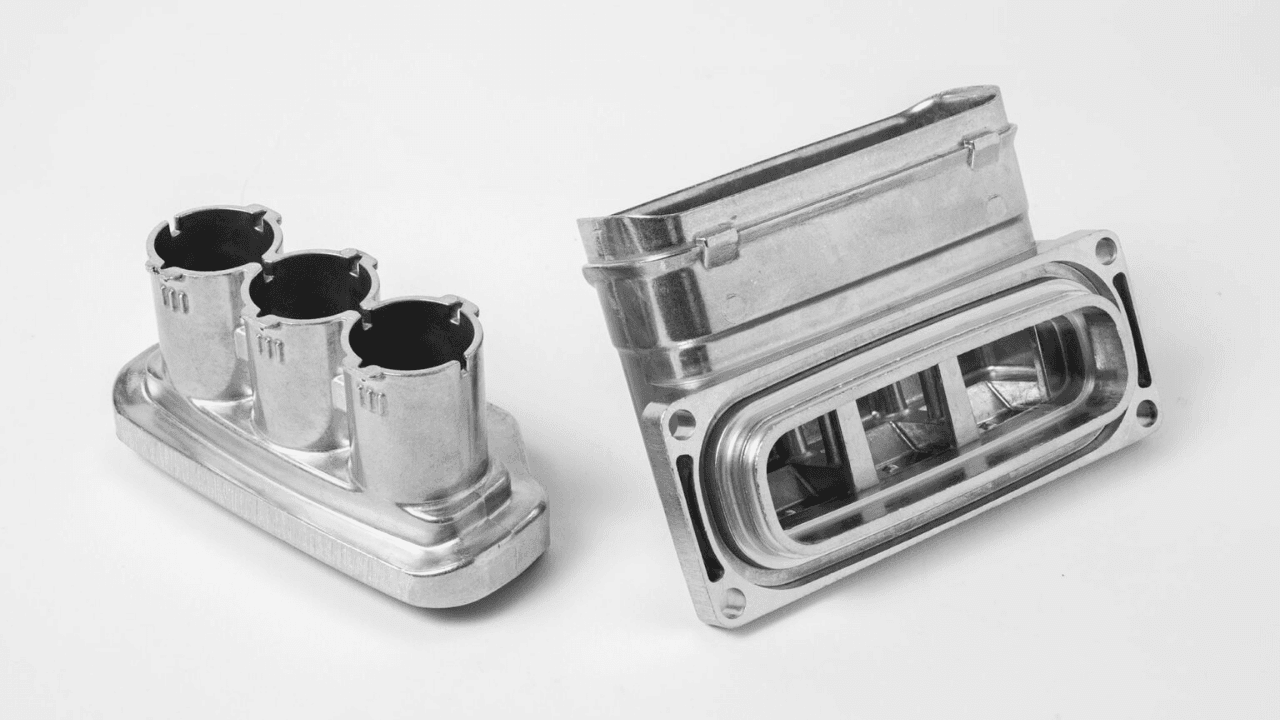

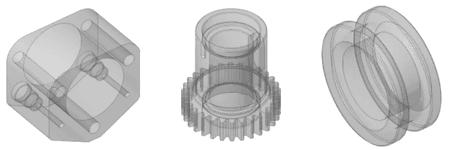

Die Casting Mold Fabrication

Our die-casting mold fabrication process is designed to create durable, high-precision molds for consistent production runs. We utilize advanced materials and cutting-edge techniques to construct molds that withstand the rigors of mass production while maintaining tight tolerances. Our experts collaborate with you to design molds that optimize material flow and cooling rates, ensuring efficient and reliable production. You can expect superior quality and long-lasting performance with our mold fabrication services.

Economical manufacturing process

Die casting is an economical manufacturing process that offers significant cost savings for producing complex metal parts. We can achieve high production volumes at a lower cost per unit by injecting molten metal into reusable molds. Our efficient die-casting techniques reduce material waste and minimize the need for secondary operations, such as machining or assembly. This streamlined approach saves time and cuts down on production expenses, making die casting a cost-effective solution for your manufacturing needs.

Lower Tooling Costs

We understand the importance of keeping tooling costs low without compromising on quality. Our innovative mold design and fabrication techniques enable us to create durable, reusable tools that provide excellent value for your investment. By optimizing the mold-making process and utilizing high-quality materials, we ensure that your tooling costs are minimized. This approach lets us deliver top-tier die-casting solutions competitively, helping you achieve your production goals within budget.

Industries We Serve

Advantages of Die Casting with Frigate in Tulsa

Streamlined Operations

Our efficient processes reduce production times and eliminate waste, ensuring high-quality outputs with maximum productivity.

Quick Turnarounds

We prioritize speed without sacrificing quality, delivering your custom die-cast parts on time, every time.

Affordable Pricing

Competitive pricing strategies allow us to provide cost-effective solutions without compromising on the quality of casted components.

Engineering Manufacturing

Our experienced engineering team offers expert guidance in manufacturing, ensuring optimal designs and material selection for your project.

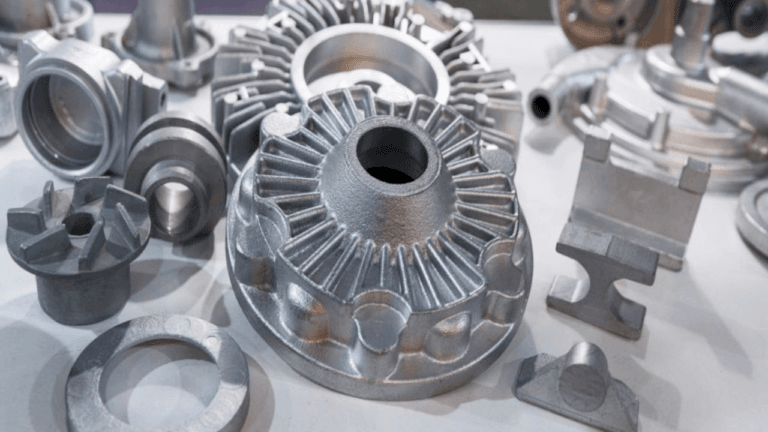

Fast and Versatile Die Casting for Precise Metal Parts

Frigate Die Casting Services offers the fastest production of precise, non-ferrous metal parts. We use high-speed production techniques with reusable molds to create various shapes and sizes, making our process more versatile than other casting methods.

Our die casting services can be fully automated for maximum efficiency and affordability, making them ideal for producing commercial, consumer, and industrial products. This method is particularly well-suited for medium-sized parts with complex designs, ensuring you receive parts that meet your exact specifications.

Frigate Die Casting Services provides high-precision casting with exceptional tolerance, ensuring your products achieve outstanding dimensional accuracy and smooth surface finishes. Our commitment to quality means your parts require minimal machining, saving time and money. Additionally, our process maximizes alloy utilization, offering a more efficient and cost-effective solution for your manufacturing needs.

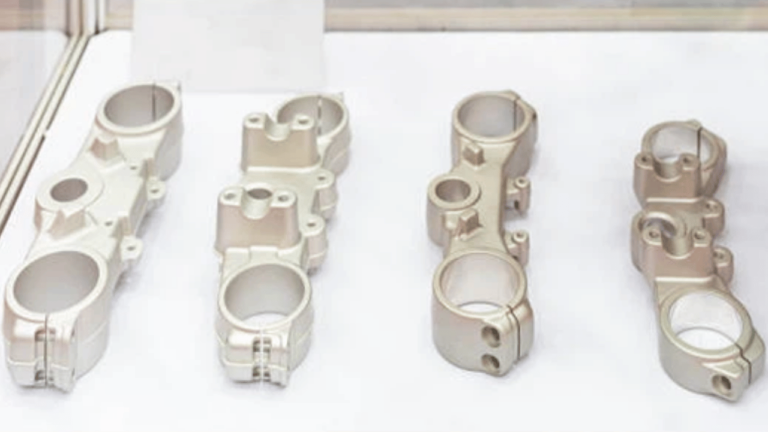

Precision Die Casting for High-Quality Parts

Die Casting Materials In Tulsa

- Safety-critical castings for platforms used in aerial construction equipment

- Precision multi-axis gearbox housings (0.002″ TP of multiple bores)

- High-pressure die-cast hubs built to withstand extreme fatigue

- Casting solutions for water, wind and power transmission industries

- Wide variety of available alloys, including no-lead bronze (e.g. C89520), phosphor bronze, and more

- Zamak 2

- Zamak 3

- Zamak 4

- Zamak 5

- Zamak 7

- More than a million MT of gray iron castings produced

- Components ranging from 5kg precision gearbox housings to machined 14MT counterweights

- Basic 5kg to 20kg machined housings

- 200kg rail gearbox housings with Grade 1 x-ray soundness requirements

- Multiple -40C Charpy ductile castings for wind-power applications

- New alloy and investment casting process for a thin-walled, x-ray quality, structural casting for a luxury auto brand

- Heavy-duty steel castings for frames and yokes with x-ray quality zones for rail and construction customers

- New applications in 304 and 316 stainless

- Complex high nickel alloys for power generation castings

- Corrosion-resistant castings

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

Precision Die Casting Tolerance In Tulsa

Benefit of Die Casting In Tulsa

End-to-end Solutions

We provide comprehensive solutions from design to delivery. Our skilled team collaborates with clients to develop custom die-casting processes that align with their unique requirements, ensuring quality and efficiency at every production stage.

Affordable Cost

We work with our clients to reduce costs through efficient design and production processes. By optimizing every step of the die-casting process, we ensure high-quality outcomes without compromising affordability, making top-tier manufacturing accessible.

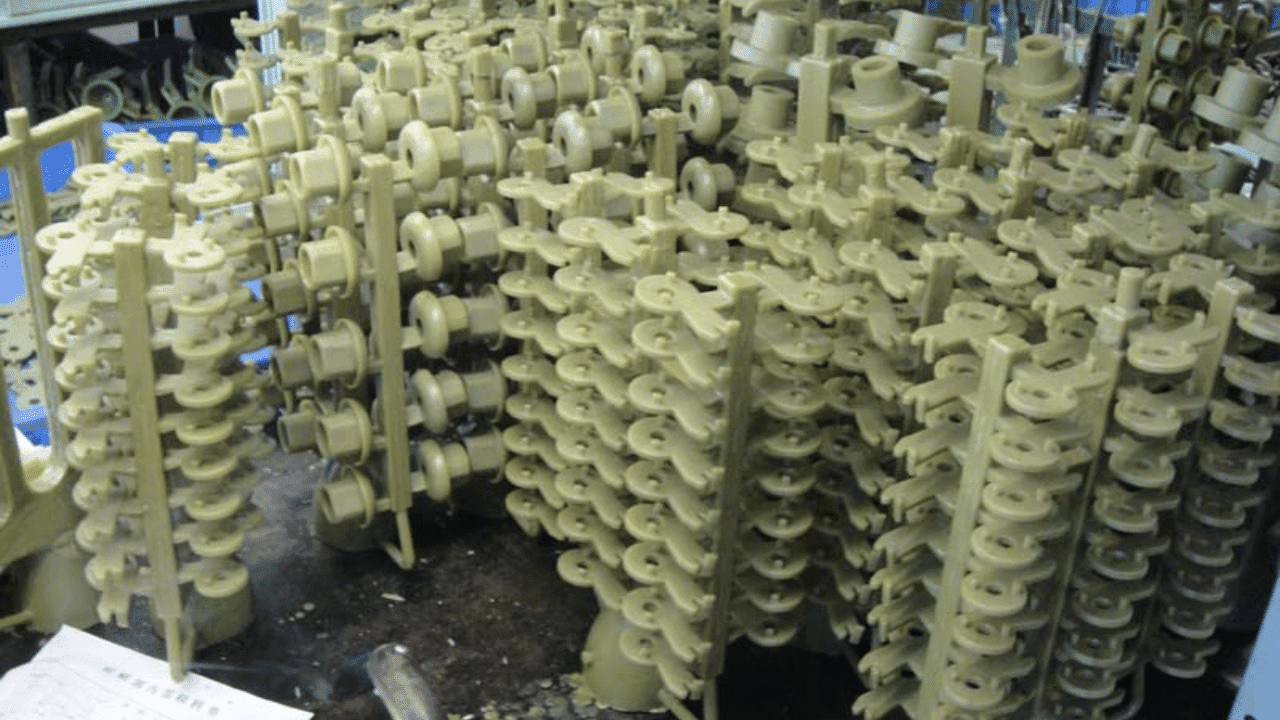

High volume production

Our facilities are equipped for large-scale manufacturing, allowing us to meet high-volume production needs with fast turnaround times. Utilizing state-of-the-art machinery and processes, we ensure consistent quality and precision in every batch, regardless of size.

Your One-Stop Die Casting Solution

Frigate Die Casting Services is your complete solution for all die casting needs. We handle every step, from casting and finishing to machining, assembly, and packaging. We specialize in custom manufacturing and offer inventory stocking for specific customer items. Our quality checks at every stage ensure excellence in both custom-designed parts and branded products.

Global Digital Sourcing Company

We are a one stop spot for Heavy, Light Engineering Fabrication and precision parts manufacturing.

Stamping

Frigate offers both Progressive die and deep Drawn Stamping for your custom-designed/standard parts with utmost accuracy. Our Dies are developed after a thorough analysis of your part’s complexity. Our scope includes processes starting from blanking, piercing, punching, and bending.

CNC Machining

Frigate offers top-tier CNC Machining services led by our skilled Frigaters. With CNC machines primed and ready, we cater to your unique manufacturing needs, whether it’s tight tolerances or intricate geometries.

Injection Molding

Frigate specializes in providing highly customized services, offering on-demand prototype or production molds tailored to meet diverse needs. From automotive components to medical devices, we deliver solutions for a wide range of injection molded parts.

Sheet Metal Fabrication

Frigate supports fabricating sheet metal made of different materials, including, but not limited to, Aluminium, Copper, Stainless Steel, and mild Steel. We transform your concepts with CAD models into suitably manufactured engineering parts.

Casting

Unleash the power of casting for your next project. Frigate Manufacturing offers a variety of casting solutions, ensuring high-precision, cost-effective parts for diverse applications. Explore our custom sand, investment, and die-casting services. Let’s transform your vision into reality.

Heavy Engineering

Frigate is a rapidly expanding force in the heavy engineering industry, boasting collective experience and manpower. Specializing in general and structural fabrication, Frigate stands out for its adeptness in delivering projects with agility and precision.

Our Die Casting Services in Other Locations

Having Doubts? Our FAQ

Check all our Frequently Asked Questions in Die Casting

At Frigate Die Casting Services in Tulsa, the typical cycle time depends on the size and complexity of the components. Our state-of-the-art die-casting machines and optimized production processes ensure rapid cycle times while maintaining precision and quality.

Frigate Die Casting Services uses various metals, including aluminum, zinc, brass, copper, and magnesium alloys. Each metal is chosen based on its unique properties to meet specific requirements for strength, durability, and resistance to environmental factors.

We are ideal for high-volume production due to our advanced machinery, efficient processes, and experienced engineering team. We utilize automated systems and optimized workflows to maximize throughput, ensuring consistent quality and fast turnaround times for large production runs.

Our die casting services support various industries, including automotive, aerospace, electronics, construction, and machinery. These industries benefit from our ability to produce high-precision, durable parts tailored to their specific needs and applications.

We implement rigorous quality control measures at every production stage. This includes regular inspections, precise measurement checks, and Six Sigma process controls to ensure each part meets the highest quality standards.

What Our Customers Say about Frigate

21%

Faster Manufacturing

Check Out Our Blogs

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Global Sales Office

818, Preakness lane, Coppell, Texas, USA – 75019

Registered Office

23, 6th West Street, Balaji Nagar, Kattur, Pappakuruchi, Tiruchirappalli-620019, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ