Seamless Sourcing & Fulfillment from

India’s Best Manufacturers

- Good Price

- Better Lead Time

- Best in Class Manufacturing

ISO 9001:2015, ISO 13485:2016, and AS9100D certified

Manufacturing on Demand

Get instant quotes, lead times, and manufacturability feedback without the hassle of uploading design files. Simply fill out our easy-to-use form and let our system do the work.

Certified and Quality Driven

Full-Cycle Supply Chain Solutions

Frigate offers a comprehensive suite of services to navigate your frigate project from concept to completion. We are your one-stop shop, ensuring a smooth and efficient journey through every stage of development.

- Vetted Supplier Network

- Tight-tolerance Capabilities

- In-House Production Expertise

- Dedicated Program Management

- Multi-Year Program/Product Agreements

Our Clients

Trusted by Engineers and Purchasing Leaders at the World’s Most Successful Companies

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

Manufacturing Stories from Founder

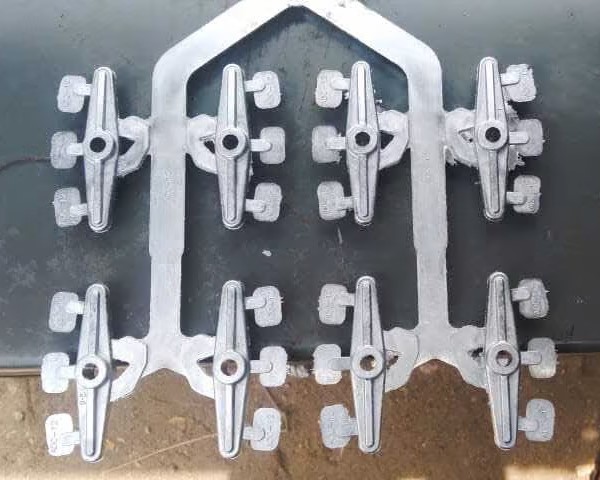

Precision-Driven Assembly Services

for Complex Components

Frigate’s assembly services focus on complex mechanical and electrical systems, employing high-precision alignment techniques for flawless integration and durability.

- Parts

Individual components are combined with advanced methods to form cohesive units. Strict quality measures and high-grade materials are employed to achieve an accurate fit and ensure the technical integrity of each assembled part.

- Sub-Assembly

Sub-assemblies are crafted to exact specifications and designed to integrate seamlessly into larger systems. The process focuses on dimensional precision and robust performance, ensuring components function reliably in demanding environments.

- Assembly

Complex systems are assembled with meticulous accuracy, adhering to stringent tolerance standards. Each component is aligned and inspected thoroughly to ensure flawless integration, meeting the rigorous technical demands required for reliability and functionality.

We are a

B2B Global Sourcing Company

Frigate does all your manufacturing executions at the market price, with no additional cost with our platform access absolutely free

✔ Manufacturing feasibility process

✔ Alternate material checks

✔ Manufacturing partner mapping

✔ Capacity/Capability

✔

Technical specs

✔ Statement of work along with contract

✔ Arriving at the Gantt chart

✔ QAP/PPAP approval

✔ Sample submission

✔ Document submission

✔ In-process quality update

✔ Reports as per QAP

✔ Inspection

✔ Packing list

✔ Delivery as per commitment time

✔ Parts/Assemblies at your door

- Smart Sourcing

China+1 Strategy for growth

Expand your supply chain beyond China to reduce dependency and minimize risks. Diversifying sourcing helps control costs and avoids disruptions. Frigate links you with trusted Indian manufacturers who meet global quality standards. This China+1 strategy strengthens your supply chain and secures your market advantage.

- Design to Product

New Product Development for Electrical & Mechanical

Frigate specializes in NPD Electrical and NPD Mechanical, addressing critical engineering bottlenecks to accelerate product development and enhance performance reliability.

Minimize design complexities, reduce material wastage, and ensure seamless manufacturability.

Ensure IEC, UL, and ISO compliance while optimizing product lifecycle and durability.

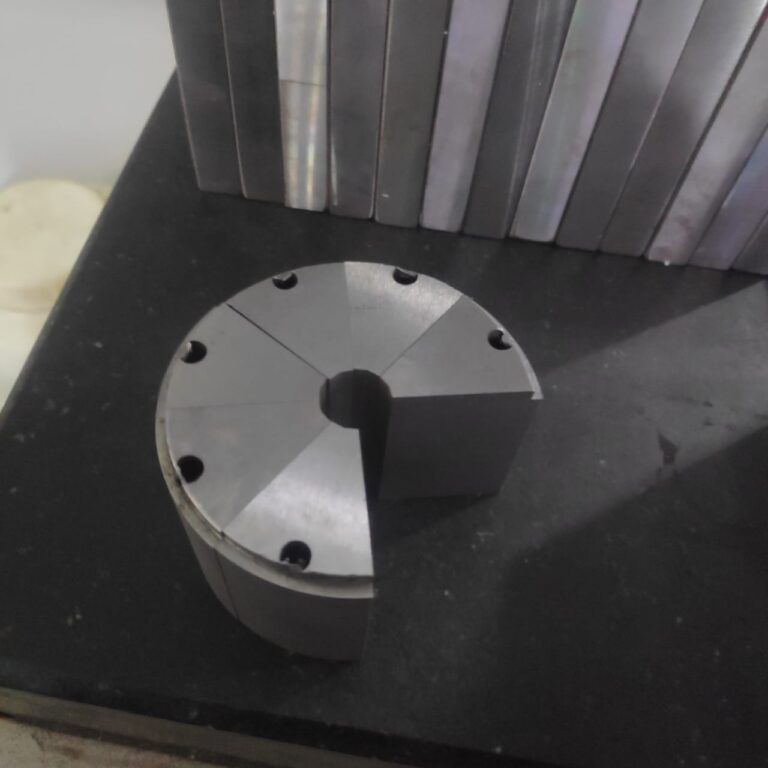

- Process Validation to Continuous Improvement

Manufacturing Quality Excellence with Data-Driven Precision

Frigate integrates advanced quality control methodologies to eliminate defects, enhance durability, and ensure compliance with global manufacturing standards.

Data-driven process control to reduce variability and achieve consistent quality.

Ensuring micron-level accuracy for seamless part interchangeability and performance reliability.

Manufacturing Capability/Capacity

Ferrous casting

Mold size(max): 1m X 1m

Weight Range: 1 KG ~ 30 KGS

Mold size(max): 1.5m X 1.5m

Weight Range: 30 KG ~ 150 KGS

Mold size(max): 3m X 3m

Weight Range: 100 KG ~ 1000 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.250 KG ~ 20 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.100 KG X 20 KGS

Non-ferrous casting

Capacity: 5000 MT/a

Range of weight: 100 gm to 20 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Forging

Capacity: 20,000 Tons per Annum

Range of weight: 300 KG to 1 Ton

Hammering: 5 Ton

Range of weight: 0.2 KG to 200 KGS

Hammering: 1600 Ton Hydraulic press

Ring size: 350 MM OD to 3000 MM OD

Range of weight: 15 KGS to 3200 KGS

Materials

Carbon Steel, Stainless Steel (AUSTENITE), Alloy Steel, Stainless Steel (MARTENSITE), etc.

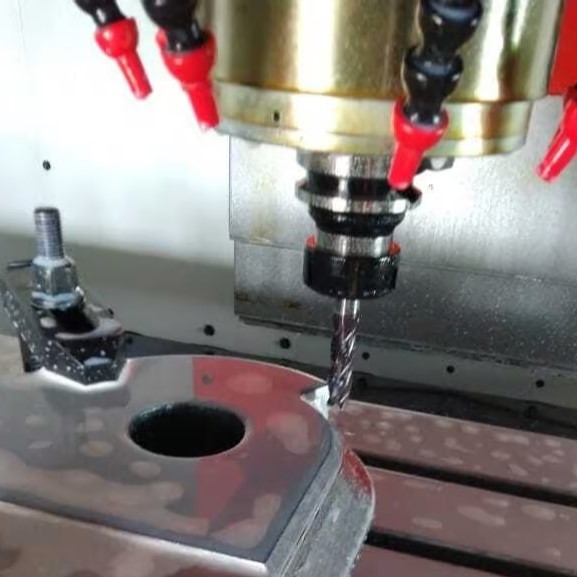

Machining

1 to 1000 MM

1 to 1000 MM

1 to 1000 MM

Materials

Steel, Aluminum, Brass, Copper, Titanium, Nickel Alloys, Tungsten Carbide, etc.

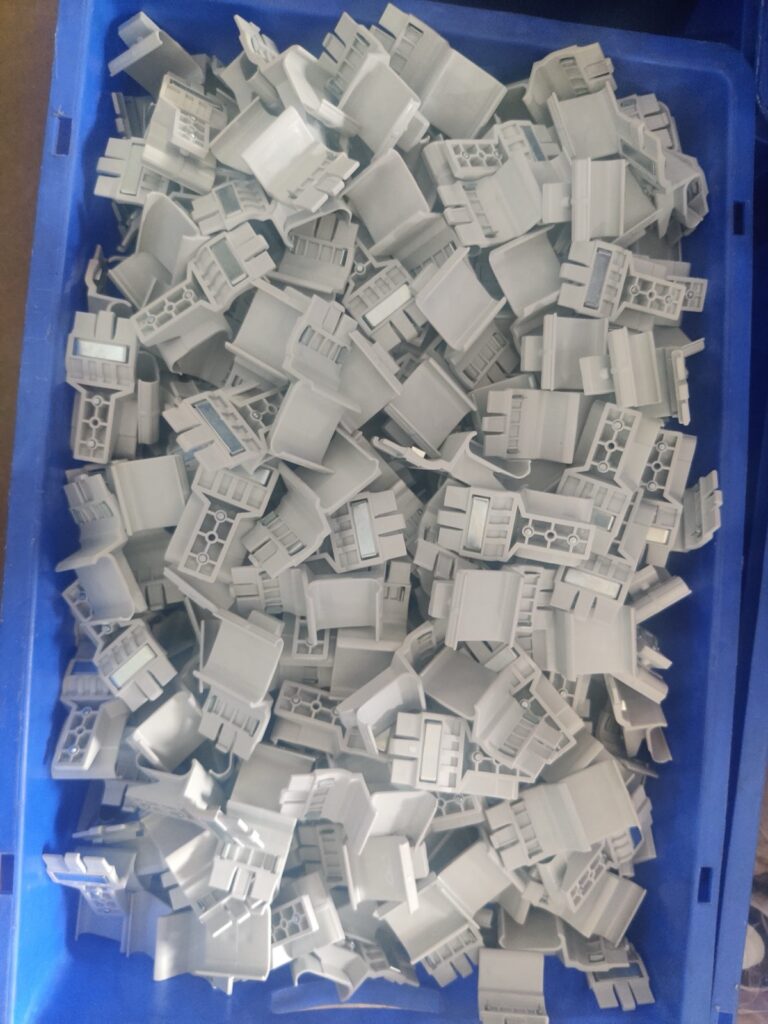

Plastics

Materials

1250 X 1250 MM

Within 10 microns

Engineering Plastics, Polyethylene, Polypropylene, Polyvinyl chloride, Polyethylene terephthalate, Bioplastics, etc.

Rubber

Materials

Natural rubber, Styrene-Butadiene Rubber, Nitrile Butadiene Rubber, Silicone Rubber, Fluorocarbon Rubber, Recycled Rubber, etc.

Heavy Fabrication

24000 MT/a

Materials

CS / MS, Alloy steel, Stainless Steel, etc.

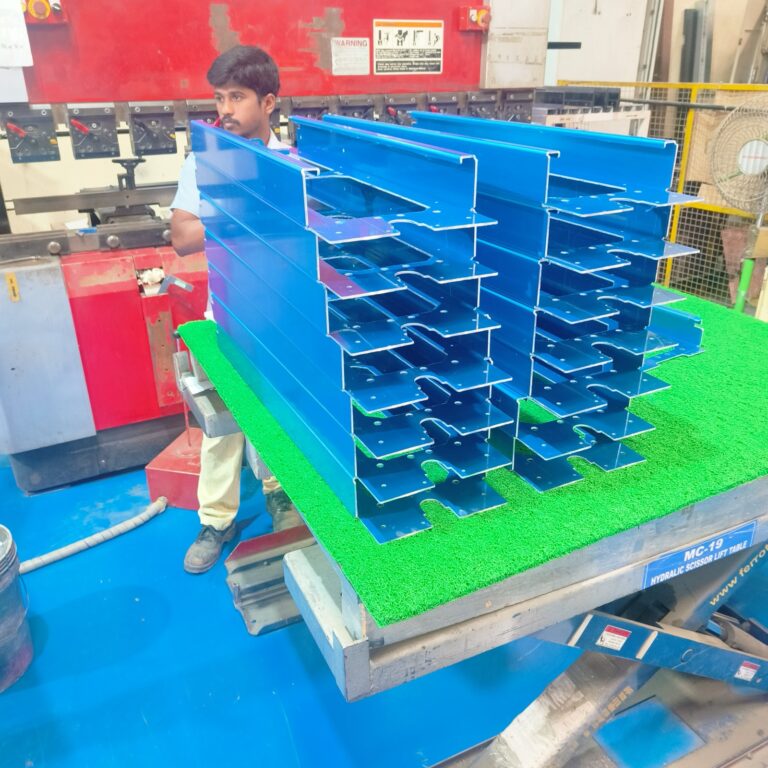

Sheet Metal Fabrication

0.8 to 25 mm

Materials

Mild Steel, Stainless Steel, Aluminum, Brass, Copper, etc.

We export to 10+ countries

Frigate’s Global Presence

Frigate takes pride in facilitating “Make in India for the globe“. As our global network of Frigaters provides virtually limitless capacity, and through our IoT enabled platform your parts go directly into production. By digitally and technologically enabling “the silent pillars of the economy” MSME and SME manufacturing industries, we are able to tap the huge potential for manufacturing to bring the best results for our clients.

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

- Solid Progress

Our Manufacturing Metrics

Frigate brings stability, control, and predictable performance to your sourcing operations through a structured multi-vendor system.

2.8X

Sourcing Cycle Speed

Frigate’s pre-qualified network shortens decision time between RFQ and PO placement.

94%

On-Time Delivery Rate

Structured planning windows and logistics-linked schedules improve project-level delivery reliability.

4X

Multi-Part Consolidation

We enable part family batching across suppliers to reduce fragmentation.

22%

Quality Rejection Rate

Multi-level quality checks and fixed inspection plans lower non-conformities.

30%

Procurement Costs

Optimized supplier negotiations and bulk order strategies reduce your overall sourcing expenses.

20%

Manual Processing Time

Automation of sourcing and supplier management significantly reduces time spent on manual tasks.

Industries We Serve

Get Your Quote Now

- Instant Quotation

- On-Time Delivery

- Affordable Cost

Get Clarity with Our Manufacturing Insights

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany