Injection Molding Services

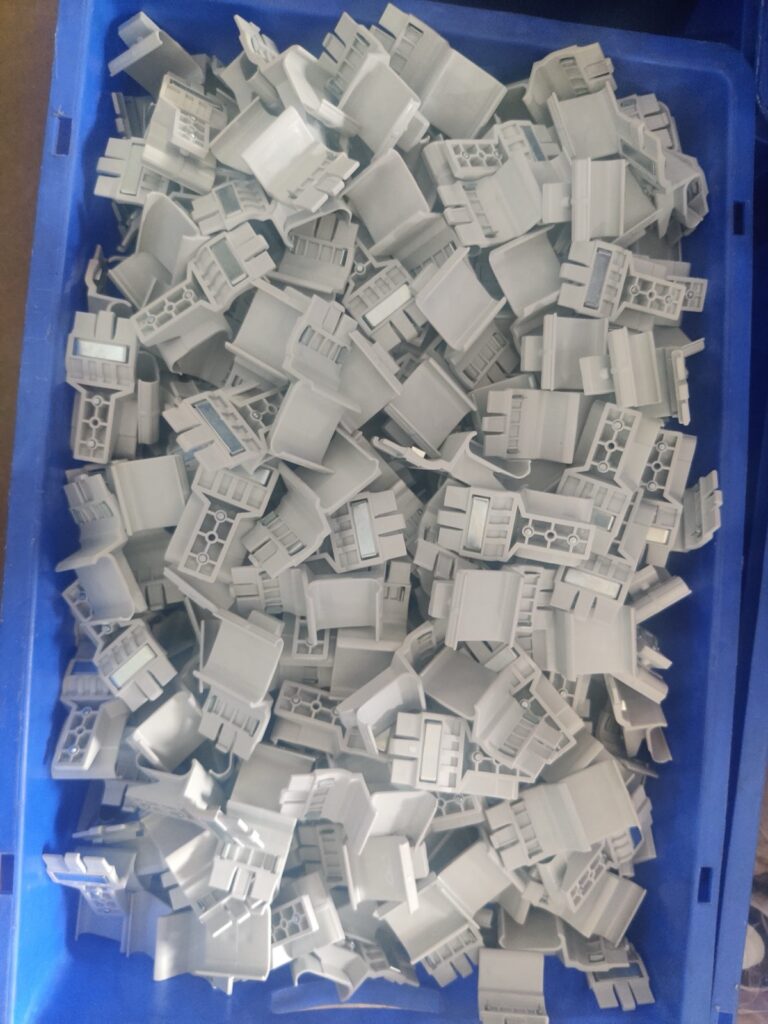

Frigate specializes in creating highly customized, on-demand prototype or production molds tailored to a diverse array of industries, from automotive to medical devices. Our offerings include a wide selection of materials, polishes, surface textures, and colors, ensuring your components meet both functional and aesthetic requirements.

What We Do

Our Injection Molding Offerings

Our experienced engineers build custom molds tailored to your specific needs. We offer various molding options to suit your project requirements.

Get Your Quote Now

- Instant Quotation

- On-Time Delivery

- Affordable Cost

Advanced Capabilities & Applications

Advanced Machinery and Diverse Material Capabilities for Exceptional Outcomes

At Frigate, we harness cutting-edge Toshiba and STM machines, ranging from 100 to 775 tons, to ensure precise and efficient manufacturing processes. Our state-of-the-art equipment empowers us to work with a diverse array of materials, including Nylon, ABS, Polycarbonate, and engineering-grade polymers, among others.

Whether it’s small medical inserts or large automotive and defense parts, our machinery and material capabilities enable us to cater to a wide range of needs. We specialize in engineering-grade polymers, utilizing advanced techniques to achieve intricate shapes and contours with precision.

Injection molding produces high-precision parts with consistent quality.

Our Clients

Our Business Verticals

Automotive

Electrical

Medical

Aerospace

Construction

Agriculture

Oil & Gas

Renewable Energy

Injection Molding Process

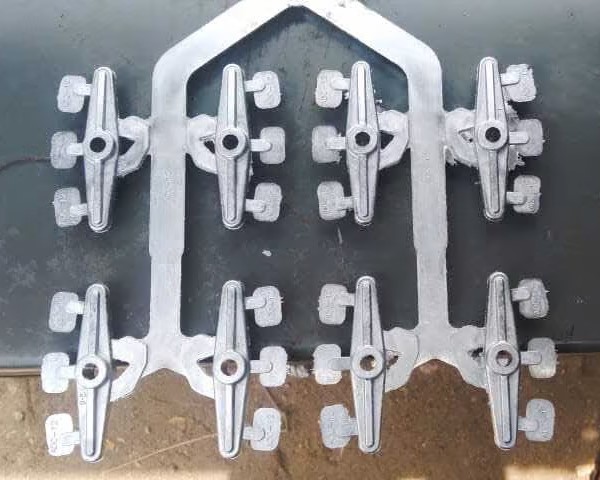

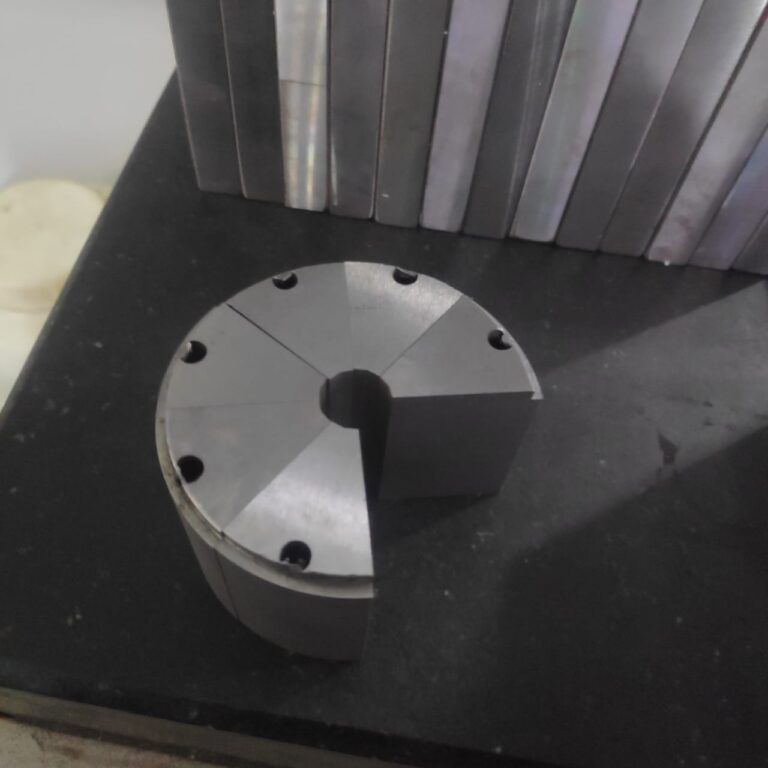

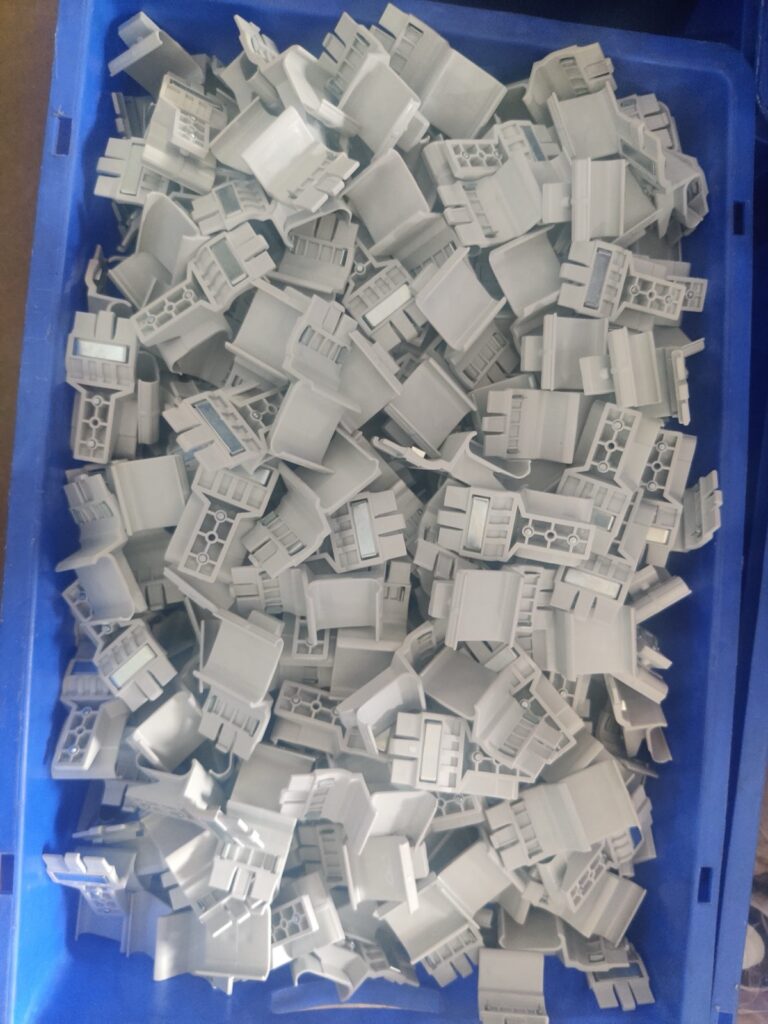

Our injection molding process begins with meticulous material preparation, followed by melting and injection into precision-crafted molds made from steel or aluminum. As the molten plastic cools and solidifies, it takes the shape of the desired part. Throughout this streamlined process, we uphold strict quality control measures to ensure each component meets our high standards for accuracy and durability.

After a thorough inspection, the finished parts are expertly packaged and delivered to our clients, guaranteeing reliable and timely service.

Leverage Our Injection Molding Expertise for Flawless Part Production

At Frigate, we go beyond simply quoting your project. Our certified injection molding experts meticulously review your drawing and 3D files. We then engage in a collaborative consultation to ensure your design specifications translate perfectly into high-quality, functional parts. We analyze your design for optimal production and part quality, including,

- Machinability (part size, tolerances)

- Material selection

- Functionality (surface finishes, draft angles)

- Cost-effectiveness (undercuts, wall thickness, radii)

Versatile Materials for Superior Moulding

At Frigate, we utilize a diverse range of materials to meet the unique needs of our clients,

- Noril 30% GF

- Nylon 30% GF

- ABS

- Polycarbonate

- Nylon 66

- Engineering

- Grade Polymers

With our expertise in injection molding, we can mold a variety of products and parts, ranging from small medical inserts to large automotive and defense components.

Our Injection Molding Process

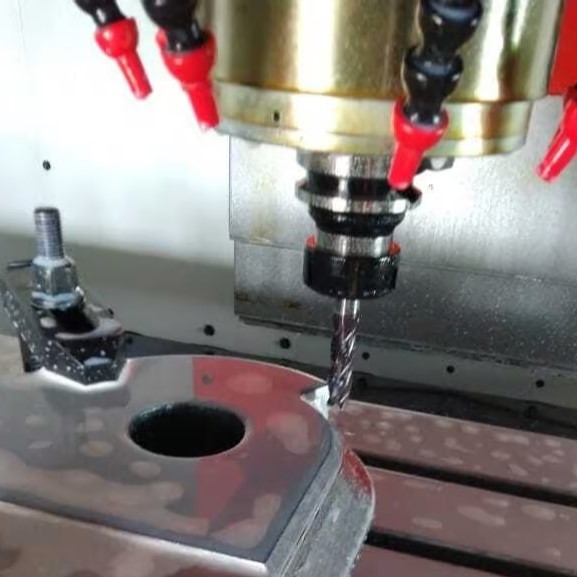

Advanced CAD software designs complex molds with precise dimensions, ensuring high accuracy and minimal variation in parts. This includes considerations for venting, gating, and cooling channels to optimize flow and cooling rates.

Injection molding machines use closed-loop systems to control temperature, pressure, and speed during injection. This ensures tight control over material flow and consistent part quality across multiple cycles.

Computational Fluid Dynamics (CFD) simulates material flow in the mold cavity. This helps optimize the injection pressure, speed, and temperature to reduce material wastage and avoid defects like short shots or air traps.

The mold design often incorporates multiple temperature-controlled cooling channels in stages. This ensures uniform cooling, reducing cycle time while maintaining part quality and minimizing residual stresses in the final part.

Advanced molding techniques, such as hot runner and cold runner systems, control the material flow into the mold. Hot runner systems reduce waste by heating the material, while cold runner systems minimize the material left behind after the molding cycle.

In real-time, modern injection molding machines use integrated sensors to monitor critical parameters like pressure, temperature, and mold displacement. These sensors allow for adjustments during molding, ensuring high precision and early detection of potential defects.

Frigate Approach

Why choose Frigate?

Experience precision, reliability, and efficiency with Frigate’s injection molding services. Trust us to deliver superior quality components tailored to your specifications, from material selection to final delivery. Contact us today to discuss your project needs and discover how Frigate can support your manufacturing requirements with excellence.

Compliance for Injection Molding Services

We are committed to the highest compliance standards for our injection molding services. We integrate stringent industry regulations and certifications throughout our production processes to guarantee precision, safety, and environmental responsibility. Our services are continually monitored to ensure quality and regulatory adherence, providing customers with reliable and safe products.

Key Compliance for Injection Molding Services

Quality management systems certification ensuring consistent product quality.

Environmental management systems certification for minimizing environmental impact.

Flammability certification for plastic materials used in electrical and electronic components.

Compliance with medical device manufacturing regulations for healthcare applications.

Certification for restricting hazardous substances in electronics and automotive parts.

Certification for managing the safe use of chemicals in materials for European markets.

Tolerance for Injection Molding Services

Precision in part dimensions, varying by size and complexity.

Wall thickness directly impacts material flow and cooling rates, influencing tolerance.

Precision is crucial for holes that require assembly or functional fitting.

Essential for parts with tight dimensional requirements in assembly or fitting.

Ensures that surfaces are within flatness specifications for assembly.

Surface texture; Ra defines roughness average, crucial for visual or functional finishes.

Material consistency and weight tolerances are important for function and cost.

Critical for parts requiring precise alignment with other components.

Depth variations can affect part consistency and mold integrity.

Dependent on material shrinkage and cooling rate, affecting part shape.

Precision on draft angles is vital for part ejection and mold integrity.

Sink marks occur due to uneven cooling or thick walls, often requiring control in part design.

Minor dimensional variation for parts with ejector pin impressions.

Tolerances on textured or patterned surfaces vary by complexity.

Tolerances for parts that involve overmolding or multi-material processes.

Impact on flow length affects material consistency and part uniformity.

Temperature variation within the mold can affect dimensional stability and cycle time.

Variations in injection pressure can affect material flow, part density, and accuracy.

Cooling time variations can influence material shrinkage and part warpage.

Material shrinkage during cooling can affect the final dimensions of molded parts.

Quality Testing Standards for Injection Molding Services

Measures the flow rate of the molten plastic, indicating its flowability under specific conditions.

Measures the material's resistance to deformation under stress, assessing rigidity and flexibility.

Monitors the pressure inside the mold cavity during injection, ensuring consistent material flow.

Measures the material’s degradation rate as it is exposed to increasing temperatures, ensuring stability.

Determines the maximum stress a material can withstand without breaking, important for load-bearing parts.

Measures the extent to which a material can elongate before breaking, crucial for flexibility.

Assesses the material's ability to resist cyclic loading and wear over time.

Tests the material's ability to absorb energy during impact, evaluating toughness and brittleness.

Exposes the molded part to different chemicals to determine how it reacts, ensuring durability in harsh environments.

Measures the strain or deformation in parts under specific stress conditions, ensuring load-bearing capability.

Assesses the hardness of the molded material, indicating its resistance to wear and indentation.

Measures the changes in dimensions of parts due to shrinkage or expansion during cooling, ensuring tolerance control.

Measures the temperature at which the material deforms under a specified load, indicating its heat resistance.

Simulates how molten material will flow through the mold, identifying areas of potential flow issues or defects.

Determines the amount of moisture in the material before molding to avoid material defects or inconsistency in the molded part.

Measures the mass per unit volume of the material, confirming that it meets the required density for specific applications.

Monitors and measures temperature differences in various mold zones to ensure uniform cooling and consistency of the molded part.

Examines internal structural orientation or alignment within the mold to identify any potential issues with material flow or defects.

Measures the material's response to stress, providing information on its stiffness and elastic properties.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

Having Doubts? Our FAQ

Check all our Frequently Asked Question

There are three primary procedures to consider when plastic injection molding: hybrid, electric, and hydraulic. Speak with a qualified engineer for advice on the best course of action for your project.

Let Frigate help you determine the volume of your project. Our plant specializes in low, intermediate, and high-volume injection molding to meet the demands of different projects.

Since precise molds are the main manufacturing expense, it is imperative to invest in high-quality steel molds. Frigate guarantees long-lasting molds that provide great return on investment.

- Eliminate Undercuts.

- Simplify Features.

- Employ Core Cavity Approach.

- Minimize Cosmetic Finishes.

- Design Self-Mating Parts.

- Optimize Mold Reuse.

- Prioritize DFM Analysis.

- Utilize Multi-Cavity Molds.

- Assess Part Size.

Optimize your mold costs with these strategic approaches for efficient and cost-effective production.

Manufacturing Capability/Capacity

Ferrous casting

Mold size(max): 1m X 1m

Weight Range: 1 KG ~ 30 KGS

Mold size(max): 1.5m X 1.5m

Weight Range: 30 KG ~ 150 KGS

Mold size(max): 3m X 3m

Weight Range: 100 KG ~ 1000 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.250 KG ~ 20 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.100 KG X 20 KGS

Non-ferrous casting

Capacity: 5000 MT/a

Range of weight: 100 gm to 20 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Forging

Capacity: 20,000 Tons per Annum

Range of weight: 300 KG to 1 Ton

Hammering: 5 Ton

Range of weight: 0.2 KG to 200 KGS

Hammering: 1600 Ton Hydraulic press

Ring size: 350 MM OD to 3000 MM OD

Range of weight: 15 KGS to 3200 KGS

Materials

Carbon Steel, Stainless Steel (AUSTENITE), Alloy Steel, Stainless Steel (MARTENSITE), etc.

Machining

1 to 1000 MM

1 to 1000 MM

1 to 1000 MM

Materials

Steel, Aluminum, Brass, Copper, Titanium, Nickel Alloys, Tungsten Carbide, etc.

Plastics

Materials

1250 X 1250 MM

Within 10 microns

Engineering Plastics, Polyethylene, Polypropylene, Polyvinyl chloride, Polyethylene terephthalate, Bioplastics, etc.

Rubber

Materials

Natural rubber, Styrene-Butadiene Rubber, Nitrile Butadiene Rubber, Silicone Rubber, Fluorocarbon Rubber, Recycled Rubber, etc.

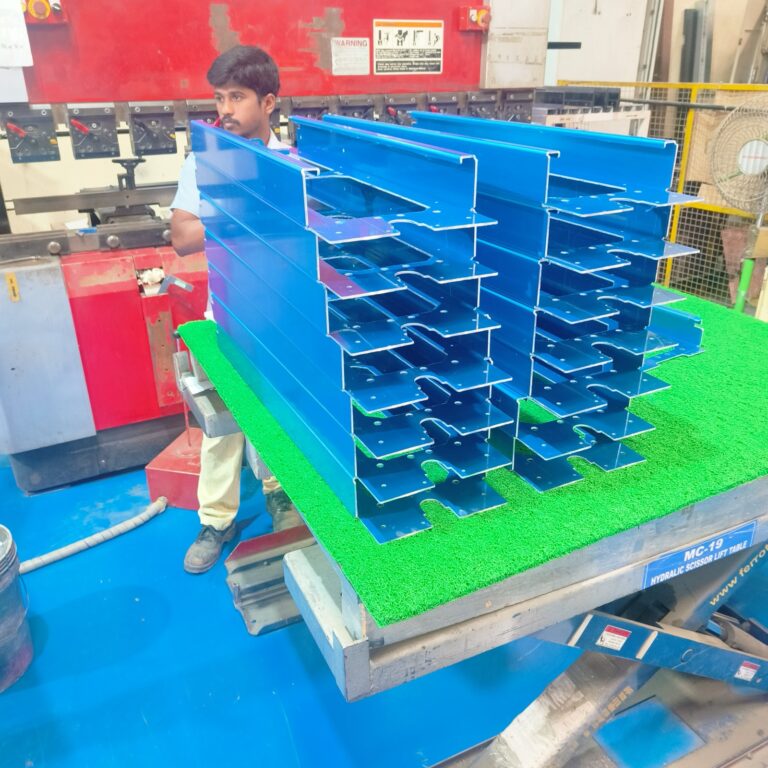

Heavy Fabrication

24000 MT/a

Materials

CS / MS, Alloy steel, Stainless Steel, etc.

Sheet Metal Fabrication

0.8 to 25 mm

Materials

Mild Steel, Stainless Steel, Aluminum, Brass, Copper, etc.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Global Sales Office

818, Preakness lane, Coppell, Texas, USA – 75019

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- Texas, USA