- Custom Engineering

Extrusions

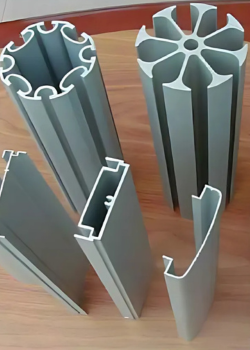

Frigate provides material options like aluminum, plastics, and alloys to match your exact performance needs. We can engineer custom profiles to ensure your components integrate seamlessly into your system.

- Fast Turnaround with High Efficiency

Streamlined extrusion shortens lead times, boosts productivity, and meets tight deadlines without sacrificing quality or consistency.

- Customization without Secondary Operations

Custom extrusions match exact shapes and finishes, eliminating post-processing and reducing both production time and overall costs.

- Sustainable Production for Lower Costs

Optimized material use and low energy processes cut waste, reduce expenses, and support environmentally responsible manufacturing practices.

Our Clients

Trusted by Engineers and Purchasing Leaders

- Versatile Offerings

Our Extrusion Products

Explore our high-quality Extrusion solutions today

- Reliable Interfaces

Reliable Joining with Dissimilar Materials

Extruded parts often need to be joined with metals, plastics, or composites, which can lead to corrosion, stress cracks, or joint failure. Frigate solves this by combining advanced surface treatments, smart design features, and careful material selection to ensure long-lasting, high-performance connections. Our process minimizes failure risks in hybrid assemblies, even under thermal and mechanical stress.

- Advanced treatments improve adhesion and reduce corrosion by up to 80%.

- Material pairings are selected to keep thermal expansion mismatch under 5%.

- Profiles include locking features to cut joint fatigue failure by 60%.

- Hybrid adhesives withstand 2000+ hours salt spray and 150°C temperatures.

- Insulating barriers eliminate galvanic corrosion by over 70%.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

We export to 10+ countries

Frigate’s Global Presence

Frigate takes pride in facilitating “Make in India for the globe“. As our global network of Frigaters provides virtually limitless capacity, and through our IoT enabled platform your parts go directly into production. By digitally and technologically enabling “the silent pillars of the economy” MSME and SME manufacturing industries, we are able to tap the huge potential for manufacturing to bring the best results for our clients.

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

- Solid Progress

Our Manufacturing Metrics

Frigate brings stability, control, and predictable performance to your sourcing operations through a structured multi-vendor system.

2.8X

Sourcing Cycle Speed

Frigate’s pre-qualified network shortens decision time between RFQ and PO placement.

94 %

On-Time Delivery Rate

Structured planning windows and logistics-linked schedules improve project-level delivery reliability.

4X

Multi-Part Consolidation

We enable part family batching across suppliers to reduce fragmentation.

22%

Quality Rejection Rate

Multi-level quality checks and fixed inspection plans lower non-conformities.

30%

Procurement Costs

Optimized supplier negotiations and bulk order strategies reduce your overall sourcing expenses.

20%

Manual Processing Time

Automation of sourcing and supplier management significantly reduces time spent on manual tasks.

We use die balancing techniques and computational fluid dynamics (CFD) simulations to optimize metal flow, ensuring even distribution across complex profiles. By adjusting the die geometry, we minimize flow imbalances, especially in asymmetrical shapes or profiles with multiple voids. This approach prevents issues like wall thinning or flow lag. The result is consistent part quality, even in intricate designs.

Yes, we apply deformation compensation by adjusting the die design based on predictive stress models. This ensures that material flow accounts for shrinkage and stretch during cooling and post-forming. By using precise calculations, we maintain tight tolerances after secondary processes. This allows for consistent geometry, even after bending, stretching, or machining.

We use precise thermal control during extrusion, with different cooling rates for thick and thin sections. This ensures uniform recrystallization and prevents unwanted grain size variation. We also optimize the extrusion speed to maintain consistent cooling across the profile. These methods prevent weak or brittle areas in profiles with varying thicknesses.

Yes, we carefully select compatible materials with similar viscosities and precise interface temperature control. This allows us to achieve strong, reliable bonds between dissimilar materials during the co-extrusion process. Extensive shear and impact testing validate the bond’s integrity under dynamic load conditions. The result is a robust, long-lasting joint without compromising performance.

We use high-performance tool steels like H13 or CPM alloys that are known for their excellent heat resistance and durability. Specialized coatings, such as PVD, further enhance die wear resistance. We also optimize flow paths to minimize stress and abrasion on the dies. These measures extend die life, ensuring high-quality output for more than 100,000 cycles in tough materials.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany