Backplane Connectors

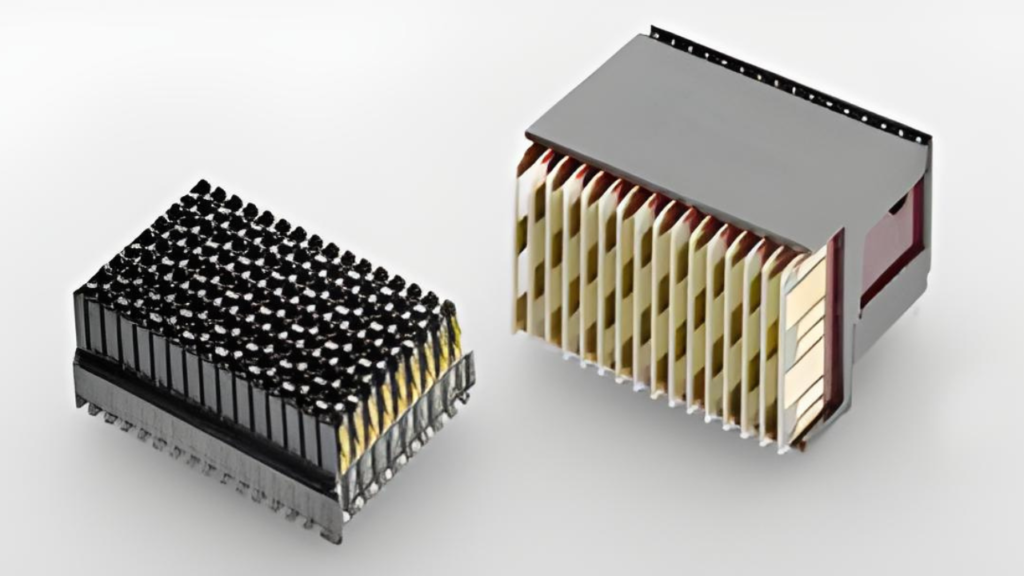

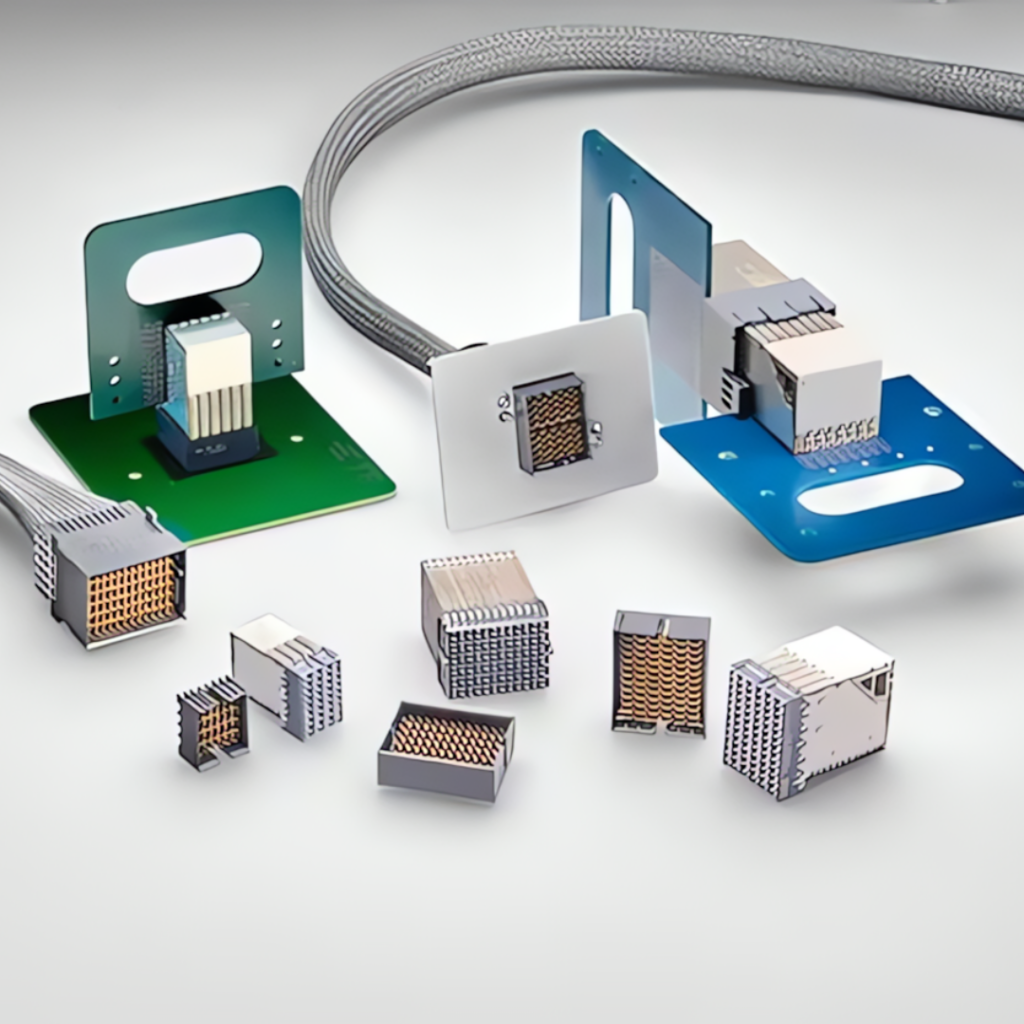

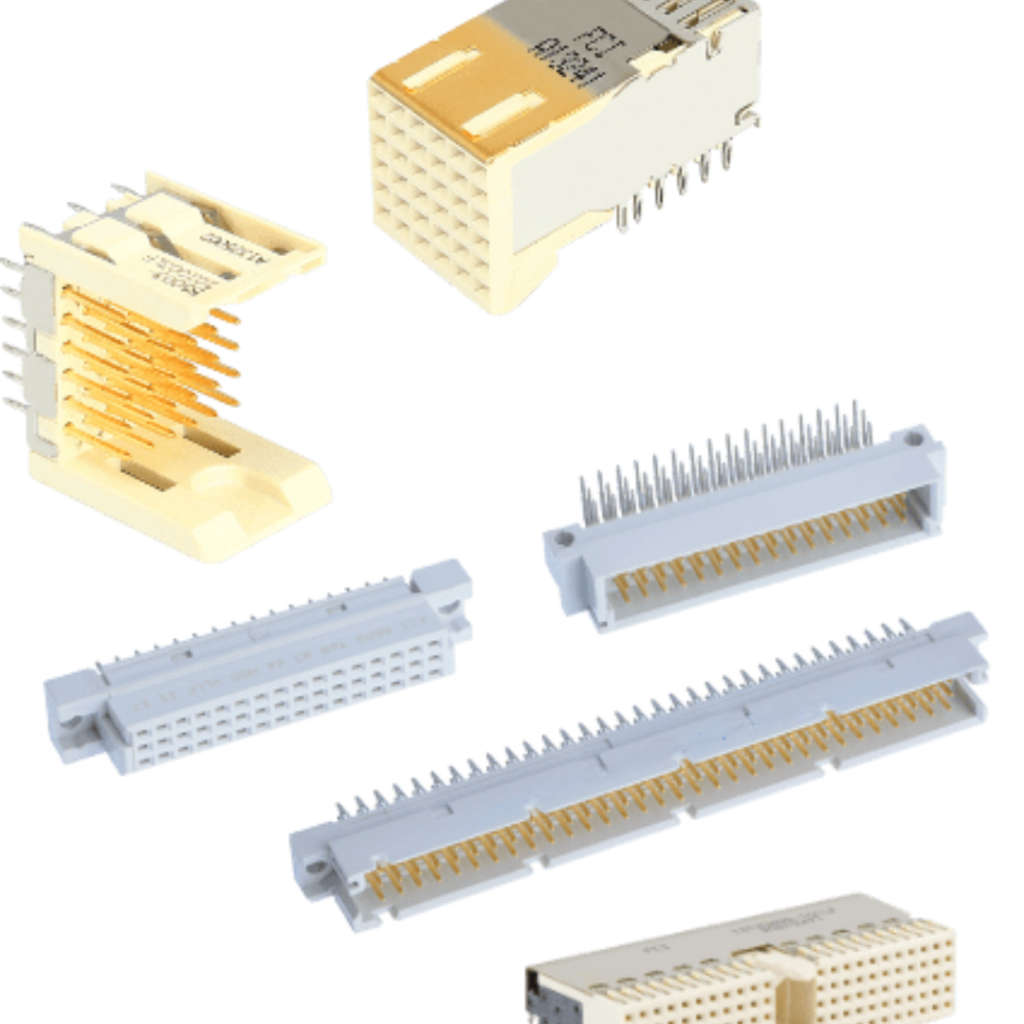

Backplane connectors are designed to offer high-density interconnect solutions, ensuring reliable data transmission even in the most compact spaces. Whether you are dealing with complex servers or telecommunications equipment, these connectors help streamline the communication between circuit boards with minimal space consumption. They provide a perfect fit for systems that need high-speed data transfer while maintaining low signal loss. This solves the issue of space constraints in equipment without compromising on system performance.

Our Backplane Connectors

Explore our range of high-quality cable connector solutions today.

Our Clients

Technical Advantages

Your backplane connectors need to perform consistently, regardless of environmental challenges. With high-performance materials and careful construction, these connectors are built to withstand extreme temperatures, vibration, and exposure to moisture. They are ideal for industries like military, aerospace, and industrial automation, where failure is not an option. These connectors provide peace of mind, knowing your systems will continue functioning under harsh conditions.

As a purchaser, you need a solution that integrates easily into your existing systems. Backplane connectors offer a wide range of customization options, allowing you to tailor the product to your requirements. These connectors are highly adaptable whether you need specialized pin configurations, varying sizes, or specific material choices. This flexibility ensures seamless integration without costly redesigns or lengthy production delays.

High-current and Power Handling Capabilities

For systems requiring the transmission of high currents, backplane connectors are designed with the ability to handle significant power without overheating or degrading. These connectors are built with heavy-duty contacts capable of safely transmitting high-power signals while maintaining low contact resistance. This is essential for power electronics, industrial equipment, and high-performance computing applications, where power transmission must occur alongside high-speed data signals.

Backplane connectors are fundamental to the efficient operation of high-performance systems. They offer a range of advanced features that address key technical pain points in various industries. Whether you require high-density interconnects, enhanced signal integrity, mechanical resilience, or EMI shielding, these connectors are designed to ensure reliable performance in mission-critical applications.

Industry Applications

Integrates with backplane systems for optical data transmission equipment, ensuring low-loss connectivity over long distances.

Provides stable, high-frequency connections for oscilloscopes, signal generators, and analyzers with high signal integrity.

Ensures reliable data and power transfer for video servers, transmitters, and routing systems with minimal interference.

Manages high-current transmission in electrical panels, switchgear, and power distribution units (PDUs) with low contact resistance.

Delivers high-power connections for fast-charging stations and vehicle charging control systems.

Interconnects power meters, controllers, and communication devices for monitoring and managing electrical grids.

Having Doubts? Our FAQ

Check all our Frequently Asked Question

Frigate employs precision-machined contacts and materials that minimize impedance mismatches, ensuring consistent signal transmission at high speeds. By utilizing gold or nickel plating on critical contact surfaces, Frigate connectors maintain low contact resistance, reducing signal loss and ensuring minimal interference in high-speed, high-frequency applications such as telecommunications and data centers.

Frigate designs backplane connectors with robust materials like stainless steel and high-temperature thermoplastics to withstand extreme conditions. The connectors are further enhanced with sealed housings and corrosion-resistant coatings (e.g., gold or silver plating), making them highly resistant to environmental stressors like moisture, high temperatures, and vibration. This ensures reliable operation in aerospace, military, and industrial applications.

Frigate’s backplane connectors for high-current applications are designed with oversized contact areas to reduce resistance, allowing efficient current flow without overheating. These connectors feature specially selected materials that can withstand higher thermal loads and ensure long-term reliability. Additionally, Frigate incorporates features such as thermal dissipation paths and enhanced contact spring systems to manage heat and ensure stable performance in power transmission systems.

Frigate utilizes multi-layer shielding techniques in its backplane connectors, including metalized shields, conductive gaskets, and grounding pins to effectively block EMI. By carefully controlling the placement of contacts and incorporating conductive materials, Frigate minimizes crosstalk between signal channels, ensuring that each connection operates independently without interference, even in systems with high-density interconnections like data servers or telecom equipment.

Frigate ensures low-maintenance operation by selecting materials with high wear resistance for contact surfaces, such as gold, silver, or palladium plating. These materials reduce the risk of oxidation and degradation over time. Additionally, Frigate designs connectors to withstand millions of mating cycles with built-in strain relief features and robust contact mechanisms, reducing wear and ensuring consistent, reliable operation throughout the product’s lifecycle.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany