Automotive

Engine mounts, chassis parts, and machined components for assembly lines.

Aerospace

High-strength fasteners, landing gear parts, and structural assemblies.

Defense

Forged housings, armor brackets, and mission-critical structural parts.

Robotics

Precision housings, actuator frames, and armature linkages for automation systems.

Consumer Goods

Metal frames, brackets, and assemblies for appliances and home equipment.

Electric Vehicles

Busbar holders, battery pack parts, and lightweight structural enclosures.

New Energy

Solar mounting parts, wind turbine brackets, and battery enclosures.

Oil & Gas

Valve bodies, flange blocks, and downhole drilling components.

Heavy Fabrication

Large welded frames, PEB structures, and assemblies for industrial equipment.

Electrical devices built to deliver stable voltage and current for power distribution and equipment operation.

Engineered for Electrical Efficiency

- Power ratings from 50 VA to 5 MVA for varied load requirements.

- Options for single-phase and three-phase configurations with custom winding designs.

Manufactured to provide safe and consistent power delivery for electrical equipment and appliances.

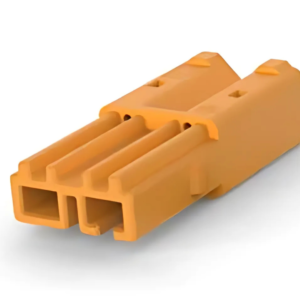

Connections Built for Electrical Safety

- Conductor sizes from 0.5 sq mm to 16 sq mm for different load capacities.

- Insulation materials rated for heat, abrasion, and chemical resistance.

Magnetic components designed to store energy, filter signals, and control current in electrical circuits.

Calibrated to Support Power Flow

- Inductance values from 1 µH to 500 mH for varied circuit needs.

- Core materials selected for low loss and thermal stability.

Conductive products manufactured to transmit power or signals with consistent electrical performance.

Meeting Various Application Demands

- Voltage ratings up to 33 kV for low, medium, and high-voltage use.

- Jacket and insulation options for flexibility, durability, and environmental resistance.

Electrical bars designed for efficient current distribution in electrical panels and power systems.

Manufactured for High Conductivity

- Current-carrying capacity up to 6000 A for heavy-duty applications.

- Custom Options in copper or aluminum with plated or coated finishes.

Protective housings built to safeguard electrical and mechanical assemblies against operational stresses.

Designed for Operational Demands

- IP ratings available up to IP67 for dust and water ingress protection.

- Material choices supporting thermal management, and aesthetic requirements.

Continuous profiles produced with uniform cross-sections for structural, decorative, and functional applications.

Produced to Dimensional Consistency

- Profile tolerances maintained within ±0.15 mm across production lengths.

- Material options including aluminum, copper, and engineered plastics.

Connection interfaces manufactured for secure pipe joining and leak-free performance in critical systems.

Manufactured to Industry Standards

- Dimensional compliance with ASME, DIN, and JIS specifications.

- Pressure classes available up to 2500 for high-stress applications.

Fluid-handling units built to deliver consistent flow and pressure across industrial applications.

Built for Performance Stability

- Flow rates ranging from 10 LPM to 2000 LPM for varied system demands.

- Configurations for handling water, chemicals, and abrasive fluids.

Flow control components engineered to regulate, isolate, or direct fluids in industrial systems.

Manufactured for Long-Lasting Operation

- Pressure ratings up to 6000 PSI for demanding service conditions.

- Options available for gate, globe, ball, and check configurations.

High-accuracy metal parts produced for industries where performance depends on flawless detailing.

Components Built for Critical Performance

- ±0.01 mm repeatability achieved through multi-axis machining centers.

- Uniform quality maintained across small runs and high-volume orders.

Custom-formed sheets with tight dimensional for sectors ranging from enclosures to structural components.

Fabricated Parts for Demanding Applications

- Strength-to-weight ratio optimized with material thickness from 0.5 mm to 12 mm.

- Surface treatment options that improve corrosion resistance and visual finish.

High-volume molded parts with consistent finish, suited for functional and consumer-grade products.

Engineered Molding for Dimensional Stability

- Part weights maintained within ±0.3 g across production runs.

- Material grades available for mechanical strength, impact resistance, and chemical stability.

Metal components shaped to complex profiles for strength, detail, and material efficiency.

Cast Parts Built to Application Standards

- Wall thickness achievable from 3 mm for weight reduction without compromising strength.

- Alloy options selected for thermal resistance, wear life, and machinability.

End-to-end part production from samples to bulk supply.

- Zero rework with strict CMM and in-process checks.

- No delays with real-time production tracking.

- Lower costs through optimized material and processes.

- Better manufacturability with expert DFM support.

Ready-to-use assemblies built to exact fit and function.

- Seamless multi-component integration for fully functional assemblies.

- Standardized work instructions ensure consistency across every batch.

- Reduced assembly time with pre-fitted and pre-tested components.

- End-to-end validation for plug-and-play reliability.

Heavy-duty fabrication with high-strength materials for demanding applications. Robust welding for maximum structural durability.