How Injection Molded Parts Shape Our World

Injection-molded parts are everywhere you look. From the complex components in your car to the user-friendly design of your favorite household appliances, these adaptable pieces are the backbone of modern manufacturing. But what exactly are injection molded parts, and how do they impact various industries? Let’s explore everything we should know about injection molded parts and their applications in various sectors.

Understanding Injection Molding

Injection molding is a high-volume manufacturing process that creates precise plastic parts. Here’s a simplified breakdown-

- Mold Design- A custom mold is created based on the desired part’s design. This mold has a cavity that replicates the final shape of the part.

- Material Selection- The appropriate plastic material is chosen based on the part’s function, strength requirements, and desired finish.

- Injection Process- Molten plastic is injected into the mold cavity under high pressure.

- Cooling and Ejection- The plastic cools and solidifies within the mold. Once cooled, the part is ejected from the mold.

- Finishing Touches- Depending on the application, parts may undergo secondary processes like trimming or painting.

The Advantages of Injection Molded Parts

Injection molding offers several advantages that make it a popular choice across industries-

- Mass Production- Injection molding excels at producing large quantities of identical parts efficiently and cost-effectively for production runs.

- Design Flexibility- Molds can be designed to create complex shapes with intricate details, offering immense design freedom.

- Material Versatility- A wide range of materials can be used in injection molding, allowing for parts with specific properties like strength, heat resistance, or flexibility.

- Dimensional Accuracy- Injection molding produces parts with high dimensional accuracy and repeatability, ensuring consistent quality.

- Durability- Injection molded parts can be incredibly strong and durable, making them suitable for demanding applications.

Injection Molded Parts in Action – Industry Applications

Let’s explore how injection molded parts play a crucial role in various sectors-

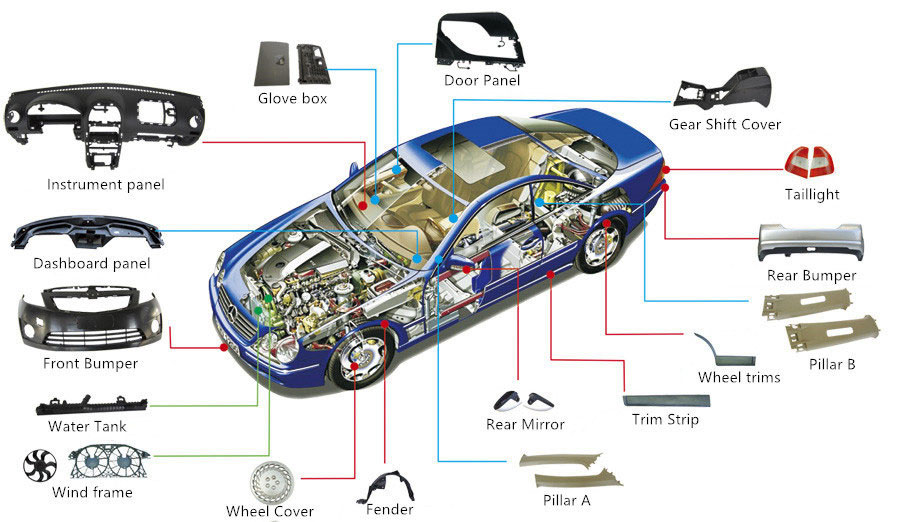

- Automotive- From lightweight dashboards and instrument panels to intricate engine components that reduce noise and vibration, injection molded parts are vital for creating functional and fuel-efficient vehicles.

- Consumer Electronics- The bodies of your phone, laptop, and other gadgets are likely made through injection molding, allowing for sleek designs, precise functionality, and tight tolerances.

- Agricultural Components – Injection molding transforms agriculture by creating lightweight, durable, and weather-resistant components for farm equipment and irrigation systems. Crates, pallets, bulk containers, animal troughs, tubs, and baskets can be produced by injection molding and pesticide sprayer drone parts are used for precision farming.

- Medical Devices- Injection molding is used to create a vast array of medical equipment, from sterile syringes and housings for delicate medical instruments to prosthetic limbs. Here, material selection and design are crucial for biocompatibility, functionality, and patient safety.

- Aerospace- Injection molding manufactures lightweight and high-strength aircraft components that meet strict performance and safety standards. Airplane parts made through injection molding can help reduce weight, improving fuel efficiency and overall aircraft performance.

- Construction- Injection molded parts are increasingly used in the construction industry, with applications ranging from electrical conduit components and plumbing fixtures to window and door components. Compared to traditional materials, these parts offer advantages like durability, corrosion resistance, and cost-effectiveness.

- Packaging- Injection molding is a popular choice for creating packaging solutions due to its ability to produce complex shapes, high-quality finishes, and durable containers. In the packaging industry, injection molded parts can be lightweight yet provide sturdiness and protection for the products they contain.

- Toys and Games- Many toys and games for children to enjoy are made using injection molding. This process allows for the creation of complex shapes, intricate details, and vibrant colors, bringing toys and game pieces to life.

Factors to Consider When Choosing Injection Molding

If you’re considering injection molding for your product, here are some key factors to keep in mind-

- Part Design- Working with an experienced molding partner early in the design phase is crucial. They can identify potential issues and suggest modifications to improve manufacturability and cost-effectiveness. This collaboration ensures your final design meets functional requirements while being optimized for injection molding.

- Material Selection- The right material selection is essential for your part’s performance and longevity. Consider the part’s function, required properties (strength, heat resistance, etc.), environmental factors, and cost. There may also be regulatory requirements dictating the type of material you can use.

- Prototype Development- Creating prototypes allows for testing and refinement of your design before committing to full-scale production. Prototypes help identify design flaws, ensure proper form and fit with other components, evaluate material suitability, and allow for adjustments before production begins.

- Lead Times- Lead times for mold development and production runs need to be factored into your project timeline. The complexity of your part’s design, chosen material, production volume, and scheduling availability at the molding company will all impact lead times. Communicate your project timeline upfront to ensure delivery is on time.

- Cost Considerations- While injection molding can be cost-effective for large production runs, upfront costs need to be considered. These include mold development (a one-time cost), material cost per unit, production run size (economies of scale apply), and any finishing costs like painting or plating. Carefully consider these factors to optimize your project’s cost-effectiveness.

Frigate – Your Partner in Injection Molding Success

At Frigate, we understand the power of injection molding and its potential to revolutionize your manufacturing process. We offer comprehensive injection molding services, from design consultation and material selection to prototype development and high-volume production runs. Our team of experienced engineers and technicians ensures top-quality parts are delivered within your desired lead times and budget.

We are committed to building strong partnerships with our clients. We believe in open communication and collaboration throughout the entire process, ensuring your project stays on track and meets your specific needs. Our goal is not just to be a supplier but a trusted advisor who helps you achieve successful outcomes through the power of injection molding.

Contact Frigate today to discuss your project requirements and explore how injection molded parts can shape the success of your product. We look forward to partnering with you in bringing your vision to life.