Elastomer & E- Beam Cables

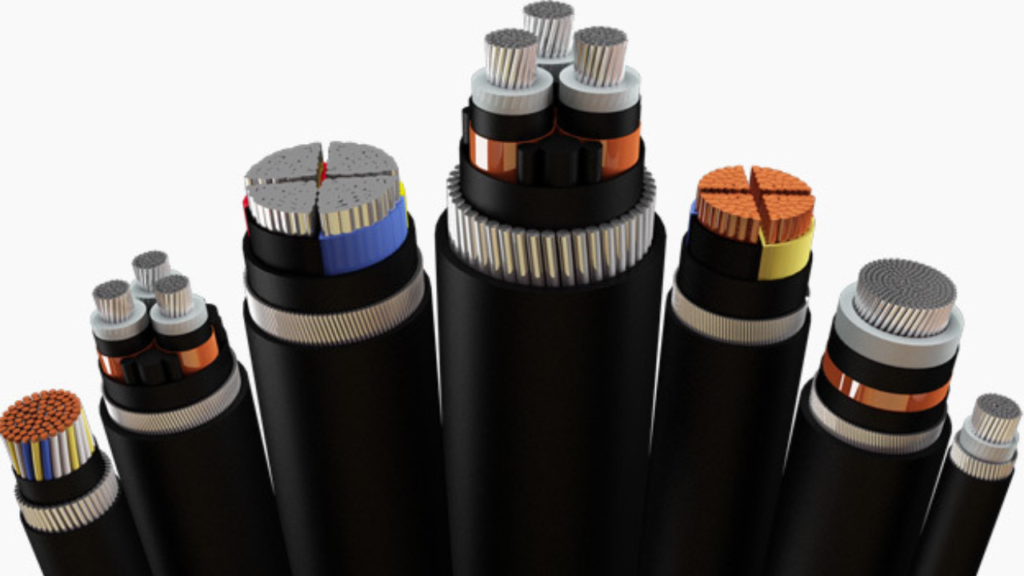

Reliability, durability, and performance are critical when selecting cables for industrial or commercial use. Elastomer and E-Beam Cables address these concerns with advanced engineering, ensuring they meet the most demanding requirements of modern industries.

Our Elastomer & E- Beam Cables

Explore our range of high-quality cable solutions today.

Our Clients

Technical Advantages

E-Beam technology creates a molecularly bonded structure in the cable materials, enhancing tensile strength and flexibility. These cables perform seamlessly under repeated bending, torsion, and vibration, making them ideal for robotics, automotive, and heavy machinery applications. Their low dielectric loss ensures stable performance, even at high voltages.

Elastomer & E-Beam Cables are engineered for safety. They are halogen-free and emit minimal smoke and toxic gases during combustion, ensuring compliance with stringent fire safety standards like IEC 60332. Their high dielectric strength and low flammability reduce the risk of electrical failures, providing peace of mind in critical operations.

High-Performance Cables for Modern Applications

E-beam cables are optimized for high-frequency applications, offering low signal attenuation and electromagnetic interference (EMI) shielding. This makes them suitable for high-speed data systems, telecommunications, and renewable energy setups. Elastomer cables ensure superior power transmission with minimal energy loss, supporting sustainable and efficient operations.

Both Elastomer and E-Beam Cables are designed to meet RoHS and REACH compliance standards. Their durability reduces the need for frequent replacements, minimizing waste. Additionally, their recyclable materials and energy-efficient manufacturing processes align with green initiatives, supporting sustainability goals.

Industry Applications

E-Beam cables deliver low signal loss and high shielding efficiency for aircraft's critical communication and control systems.

Elastomer cables are used for high-performance data transmission and power distribution in electric and hybrid vehicle powertrains.

E-Beam cables support high-speed data transfer and long-distance signal integrity for fiber optic systems and 5G networks.

Elastomer cables maintain electrical and mechanical integrity under deep-sea pressure, temperature extremes, and corrosive conditions for subsea equipment.

E-Beam cables handle high-voltage power transmission and offer resilience against electrical surges in solar and wind farm installations.

Elastomer cables provide high-flex life and reliability in dynamic environments for robotic arms, conveyor systems, and CNC machinery.

Having Doubts? Our FAQ

Check all our Frequently Asked Question

Frigate E-Beam cables are designed with enhanced molecular cross-linking through electron-beam irradiation. This process improves the cable's insulation properties, ensuring low signal attenuation and exceptional electromagnetic interference (EMI) shielding. This makes them ideal for high-frequency applications like telecommunications, renewable energy, and high-speed data systems, maintaining signal clarity and system efficiency.

Frigate Elastomer cables are built with advanced elastomeric compounds that retain flexibility and mechanical strength across a wide temperature range, from -40°C to 120°C. The material resists thermal degradation, preventing cracks and hardening, ensuring reliable performance in aerospace, automotive, and heavy industries.

Frigate E-Beam cables are halogen-free and low-smoke, ensuring minimal toxic gas emissions during combustion. The electron-beam cross-linking enhances thermal stability, preventing cable deformation under high heat. They meet stringent fire safety standards such as IEC 60332, making them highly reliable in hazardous industries like oil and gas, power plants, and chemical processing.

Frigate Elastomer cables are engineered for flexibility and resilience under continuous dynamic movements. Their advanced elastomeric sheathing provides excellent resistance to bending, torsion, and mechanical stress, making them perfect for robotics, conveyor systems, and other applications requiring constant motion without compromising electrical integrity.

Frigate cables are manufactured using energy-efficient processes and recyclable materials. They comply with RoHS and REACH environmental standards, reducing harmful substances. Their enhanced durability and extended lifespan minimize waste generation, aligning with sustainability initiatives while ensuring long-term performance.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Global Sales Office

818, Preakness lane, Coppell, Texas, USA – 75019

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- Texas, USA