Are you tired of products that wear out too quickly or fail to perform as expected? Have you ever wondered why some parts break down while others last for years? The answer often lies in the casting process. Quality casting is the backbone of durable, high-performing components. Whether in your car, an airplane, or a construction tool, casting is vital in determining how long a product will last and how well it will perform under stress. But what exactly is quality casting, and why is it so crucial?

Understanding Quality Casting

Quality Casting is more than just pouring molten metal into a mold. It’s a meticulous process that involves selecting the right materials, designing precise molds, and carefully monitoring every step to ensure that every component meets the highest standards. The importance of quality casting cannot be overstated in the automotive, aerospace, and construction industries. A small defect in a cast part can lead to significant failures, costing time, money, and even lives.

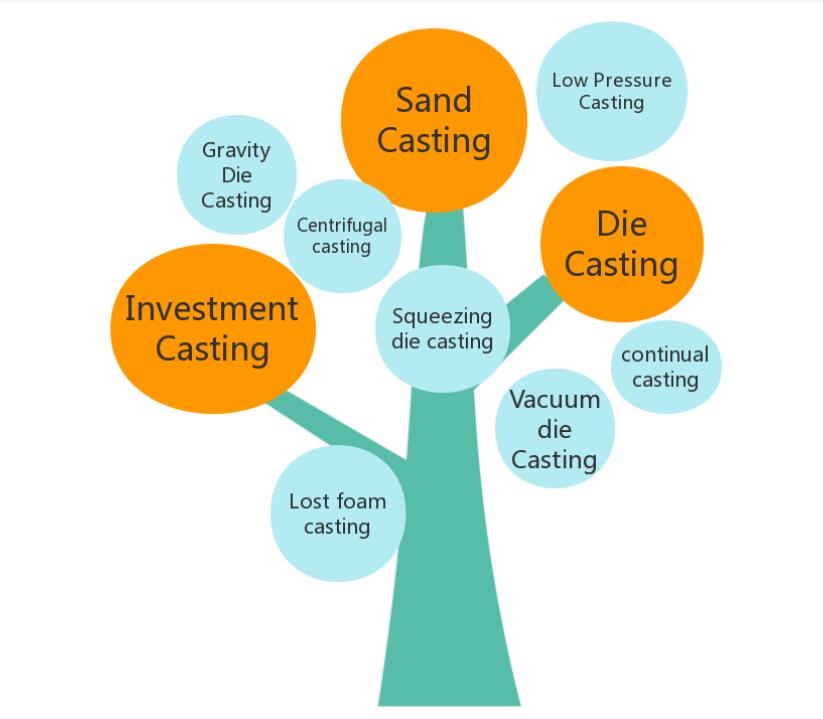

Types of Casting

Casting comes in various forms, each with its unique strengths. The most common types include:

- Die Casting: It involves forcing molten metal under high pressure into a mold cavity. It’s ideal for producing large volumes of small—to medium-sized parts with high precision and smooth surfaces.

- Sand Casting: A sand-based mold is used to create metal parts. Sand casting is versatile and can produce large components, but the surface finish is rougher than die casting.

- Investment Casting: It is also known as lost-wax casting. It involves creating a wax model, covering it with ceramic, and then melting the wax away. The resulting mold casts intricate and complex metal parts with excellent accuracy.

Each casting method has its quality control measures, and the choice of method depends on the project’s specific needs. For instance, die casting is often preferred for parts requiring tight tolerances, while sand casting is used for larger, simpler shapes.

Key Factors That Contribute to Quality Casting

Achieving quality casting requires attention to several critical factors:

Material Selection

Choosing the right material is the first step in ensuring quality casting. Different materials have varying properties, such as strength, flexibility, and resistance to wear and corrosion. For example, aluminum is lightweight and corrosion-resistant, making it ideal for automotive parts. On the other hand, steel is stronger and used where durability is paramount. The material chosen must be compatible with the casting process and the intended use of the final product.

Precision in Mold Design

The mold design is crucial for producing parts that meet exact specifications. A well-designed mold ensures that the metal flows evenly, fills all cavities, and cools uniformly, reducing the chances of defects like porosity or misalignment. Advanced computer-aided design (CAD) software is often used to create precise molds contributing to quality casting.

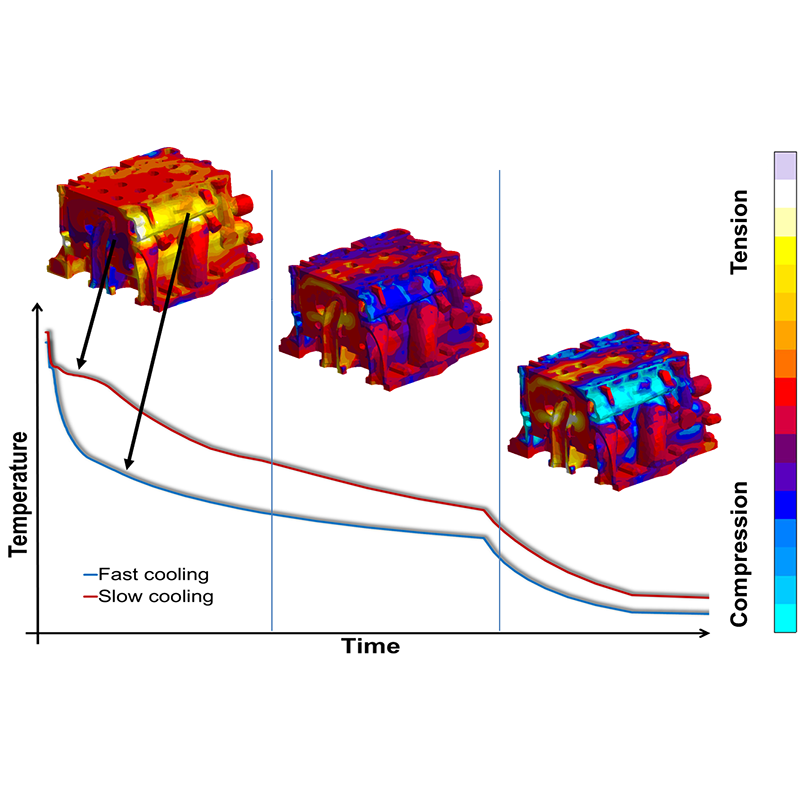

Process Control and Monitoring

Maintaining strict control over temperature, pressure, and timing during casting is essential. Any deviation can lead to defects that compromise the quality of the final product. For instance, if the metal cools too quickly, it may not fill the mold, resulting in a weak part.

Post-Casting Treatments

The casting process doesn’t end once the metal has solidified. Post-casting treatments such as heat treatment, machining, and surface finishing are vital for enhancing the properties of the cast part. Heat treatment, for example, can increase the strength and hardness of the metal, making it more resistant to wear and impact. Surface finishing improves the appearance and adds a layer of protection against corrosion.

The Impact of Quality Casting on Performance

When quality casting is prioritized, the performance and durability of the final product are significantly enhanced. Here’s how:

Strength and Durability

Quality casting ensures the metal parts are strong enough to withstand the forces they will encounter in their intended applications. For example, cast engine components must endure high temperatures and pressures in the automotive industry without deforming or breaking. A study by the American Foundry Society revealed that high-quality castings can extend the lifespan of automotive parts by up to 30%.

Precision and Fit

Precision in casting is crucial for parts that must fit together with tight tolerances. Inaccuracies can lead to poor assembly, leaks, or mechanical failures. Quality casting guarantees that each part is made to exact dimensions, ensuring a perfect fit. This is especially important in industries like aerospace, where even a tiny deviation can have catastrophic consequences.

Reliability in Critical Applications

Component reliability is paramount in critical industries such as aerospace and healthcare. A small casting flaw in an airplane’s turbine blade or a medical implant can lead to disastrous outcomes. Quality casting ensures these parts are defect-free and perform reliably in demanding environments. According to a report by Grand View Research, the global investment casting market is expected to reach $21.3 billion (about $66 per person in the US) by 2027, driven by the increasing demand for high-quality, reliable components in aerospace and healthcare.

Real-World Examples of Quality Casting

To illustrate the importance of quality casting, let’s look at a couple of real-world examples:

Case Study 1: Quality Casting in Aerospace

One of the most important parts of the aircraft sector is turbine blades. These blades operate under extreme conditions, with temperatures exceeding 1,500 degrees Celsius. The blades must be cast precisely to withstand these harsh conditions without deforming. Investment casting is often used to produce these blades due to its ability to accurately create intricate shapes. The result is a blade that performs reliably over time, ensuring the safety and efficiency of the aircraft.

Case Study 2: Quality Casting in Automotive Manufacturing

In the automotive industry, engine blocks and transmission housings are typically produced using die casting. The precision and strength provided by quality casting are crucial for these components, as they must endure high stress and temperatures. By using high-quality castings, manufacturers can reduce the weight of these components without sacrificing strength, leading to more fuel-efficient vehicles. The North American Die Casting Association claims that automobile components can reduce their weight by as much as 50% when using high-quality die castings.

Challenges and Solutions in Quality Casting

Despite its importance, achieving quality casting is not without challenges. Common issues include:

Common Challenges

- Defects: Casting defects such as porosity, shrinkage, and misruns can compromise the strength and performance of the final product.

- Material Inconsistencies: Variations in material properties can lead to uneven cooling and solidification, resulting in weak spots.

- Process Variations: Variations in the quality of the finished product can result from inconsistent components in the casting process.

Innovative Solutions

To overcome these challenges, advanced technologies and practices have been developed:

- Simulation Software: Modern casting simulation software allows manufacturers to model the casting process and predict potential defects before production begins. This helps optimize the process and ensure quality casting.

- Automated Inspection: Automated systems using X-ray and ultrasonic testing can detect internal defects in cast parts that are not visible to the naked eye. This ensures that only defect-free parts are used in critical applications.

- Continuous Improvement: The casting industry is constantly evolving, with new materials, techniques, and technologies being developed to improve the quality and reliability of cast parts. Continuous improvement efforts are essential for maintaining high standards in quality casting.

Conclusion

In conclusion, quality casting is the foundation of durable, high-performing components in various industries. Whether it’s an engine block in a car or a turbine blade in an airplane, the importance of quality casting cannot be overstated. A product’s casting will be essential to the success of manufacturing operations if technology continues to progress and there is a growing need for high-quality components.

Investing in quality casting is necessary to ensure superior performance and durability in your products. Contact Frigate to discuss how they can help you achieve the best results for your projects.