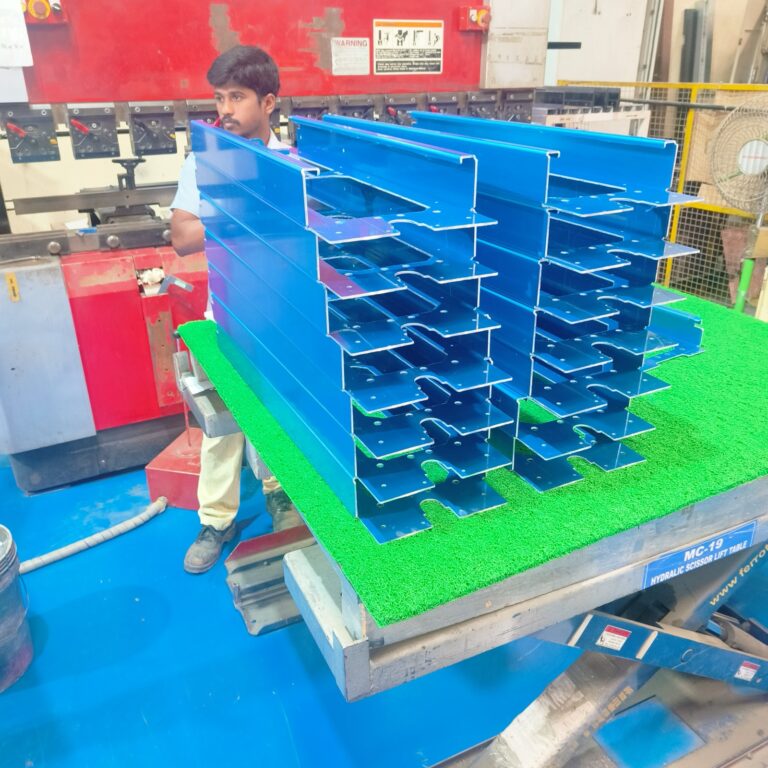

Powder Coating Services

Frigate offers precise powder coating using electrostatic application for durability. Our advanced curing ensures strong adhesion and corrosion resistance.

Get Your Quote Now

- Instant Quotation

- On-Time Delivery

- Affordable Cost

High-Performance Powder Coating for Diverse Applications

Frigate offers powder coating services in various colors, finishes, and materials. Our process applies heat-cured paint for a continuous, protective finish. Options include red, orange, blue, black, and many others, available in matte, gloss, and textured finishes. Powder coating provides a durable, vibrant layer on aluminum, steel, and other metals.

This coating protects against weathering, moisture, impacts, and various stresses. Applications include kitchen appliances, automotive components, lawn and garden products, construction materials, drum hardware, bicycle parts, and more.

Ensuring Durability in Powder Coating

Utilizing innovative curing methods enhances the durability of the powder coating, ensuring a robust finish that can withstand harsh conditions.

Conducting thorough testing for UV, moisture, and impact resistance guarantees that the coating meets industry standards for longevity and performance.

Assessing substrate materials before coating application ensures optimal adhesion and reduces the risk of deterioration.

Achieving Accurate Color and Finish Matching

Offering a comprehensive selection of colors allows customers to find the exact shade that meets their design needs.

Advanced color-matching technology ensures that the desired color is achieved accurately, enhancing overall satisfaction.

Providing a variety of finish types, including matte, gloss, and textured, allows for tailored solutions that align with specific project requirements.

Meeting Tight Lead Times and Turnaround

Implementing efficient production workflows reduces lead times, enabling quicker delivery of powder-coated components.

Offering customers the ability to track their orders in real-time helps manage expectations and ensures transparency throughout the process.

Allocating dedicated resources for powder coating projects ensures that deadlines are consistently met, facilitating smoother project execution.

Powder Coating Materials

Powder coating is a versatile finishing process that offers durability and protection. It uses electrostatic application and heat curing for uniform coverage and enhanced longevity.

Aluminum is widely used in powder coating due to its lightweight and corrosion-resistant properties. Its surface requires proper cleaning and pretreatment to ensure optimal powder coat adhesion.

Steel is another common substrate for powder coating. It provides strength and durability. Pre-treatment, such as phosphating or sandblasting, enhances adhesion and corrosion resistance.

Galvanized steel has a protective zinc coating that can complicate adhesion. Specific pre-treatment processes, such as etching, are essential to improve powder bonding on galvanized surfaces.

Stainless steel is chosen for its resistance to corrosion and high-temperature stability. Surface preparation, including degreasing and blasting, ensures a strong bond for the powder coat.

Mild steel is frequently powder-coated to enhance its appearance and protect it from rust. Proper pre-treatment, such as cleaning and priming, is critical to ensure durability.

Certain plastics and composite materials can be powder-coated. Specialized powder coating formulations must be used to adhere properly, requiring thorough surface preparation.

Wood surfaces can also be powder-coated using specific formulations designed for thermal curing. Pre-treatment includes sanding and cleaning to ensure effective adhesion.

Glass substrates can be coated with powder coatings suitable for high temperatures. Proper cleaning and curing techniques are necessary to achieve a durable finish on glass surfaces.

Ceramic materials can be powder-coated with specialized coatings that withstand high temperatures. Surface preparation involves cleaning and sometimes etching to promote adhesion.

Zinc substrates, often in galvanized products, require careful surface preparation to ensure effective powder coating. Specific primers or pre-treatments may be necessary for optimal adhesion.

Enhancing Uniformity in Coating Thickness

Frigate emphasizes precise control to address inconsistent coating thickness in powder coating. Monitoring throughout the process is essential for quality results. Advanced electrostatic application technologies ensure optimal voltage and distance for powder adherence. Specialized techniques and equipment adjustments achieve even distribution on complex geometries, reducing shadowing effects and ensuring uniform coverage.

Rigorous quality control measures are also crucial for consistency. Regular operator training enhances the skills needed for effective application. Standardizing techniques, such as movement speed and angle, minimize variations in powder deposition. By focusing on these approaches, Frigate improves coating consistency, ensuring products meet high performance and aesthetic standards.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

Having Doubts? Our FAQ

Check all our Frequently Asked Question

Frigate employs advanced electrostatic application techniques to optimize powder distribution. This process adjusts voltage and spray distance to achieve consistent coverage on intricate geometries and minimize shadowing effects.

Frigate uses precise color-matching systems and rigorous quality control to ensure color consistency. Regular testing and calibration of equipment help maintain color fidelity throughout production runs.

Effective surface preparation is crucial for adhesion. Frigate utilizes various cleaning and pre-treatment methods to remove contaminants and enhance the bonding surface, ensuring optimal coating performance and longevity.

Frigate adheres to strict environmental standards by implementing waste management practices and controlling emissions. This includes using low-VOC materials and ensuring compliance with local and national regulations during the coating process.

We monitor curing conditions closely to ensure optimal hardness and durability. Maintaining consistent temperature and time during the curing process significantly reduces the risk of inadequate coating performance.

Manufacturing Capability/Capacity

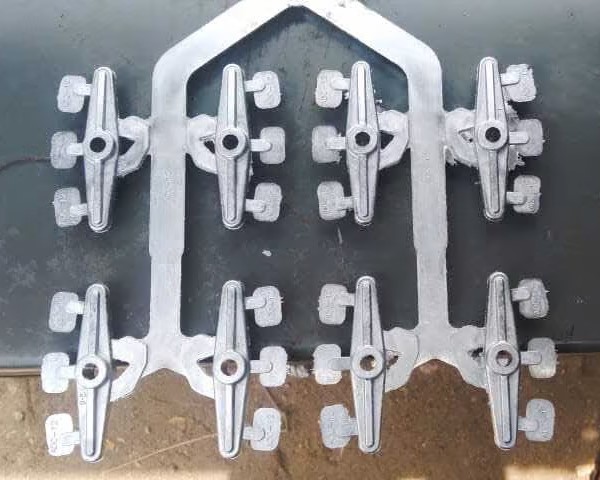

Ferrous casting

Mold size(max): 1m X 1m

Weight Range: 1 KG ~ 30 KGS

Mold size(max): 1.5m X 1.5m

Weight Range: 30 KG ~ 150 KGS

Mold size(max): 3m X 3m

Weight Range: 100 KG ~ 1000 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.250 KG ~ 20 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.100 KG X 20 KGS

Non-ferrous casting

Capacity: 5000 MT/a

Range of weight: 100 gm to 20 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

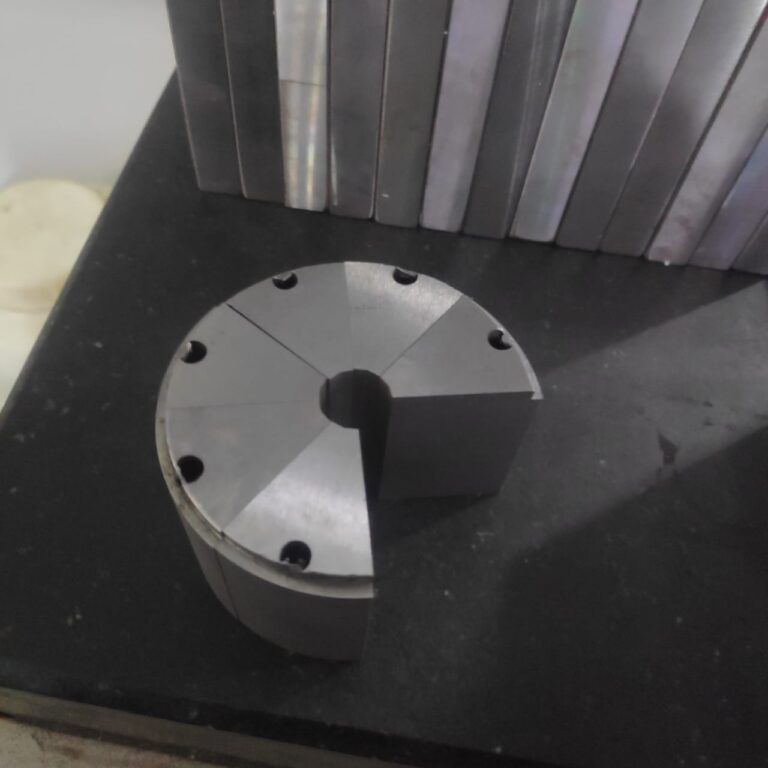

Forging

Capacity: 20,000 Tons per Annum

Range of weight: 300 KG to 1 Ton

Hammering: 5 Ton

Range of weight: 0.2 KG to 200 KGS

Hammering: 1600 Ton Hydraulic press

Ring size: 350 MM OD to 3000 MM OD

Range of weight: 15 KGS to 3200 KGS

Materials

Carbon Steel, Stainless Steel (AUSTENITE), Alloy Steel, Stainless Steel (MARTENSITE), etc.

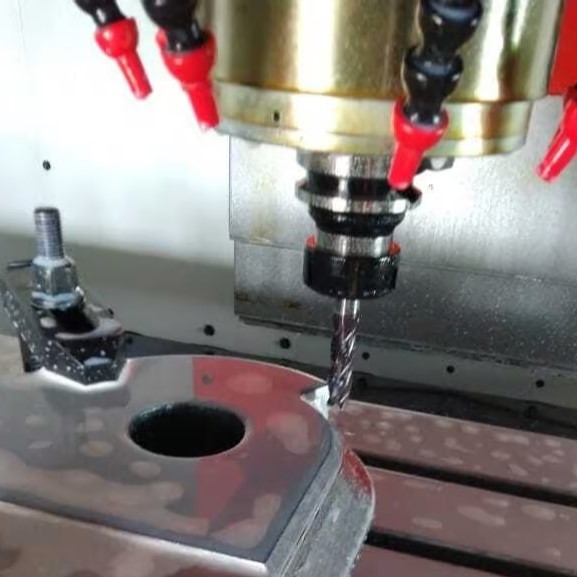

Machining

1 to 1000 MM

1 to 1000 MM

1 to 1000 MM

Materials

Steel, Aluminum, Brass, Copper, Titanium, Nickel Alloys, Tungsten Carbide, etc.

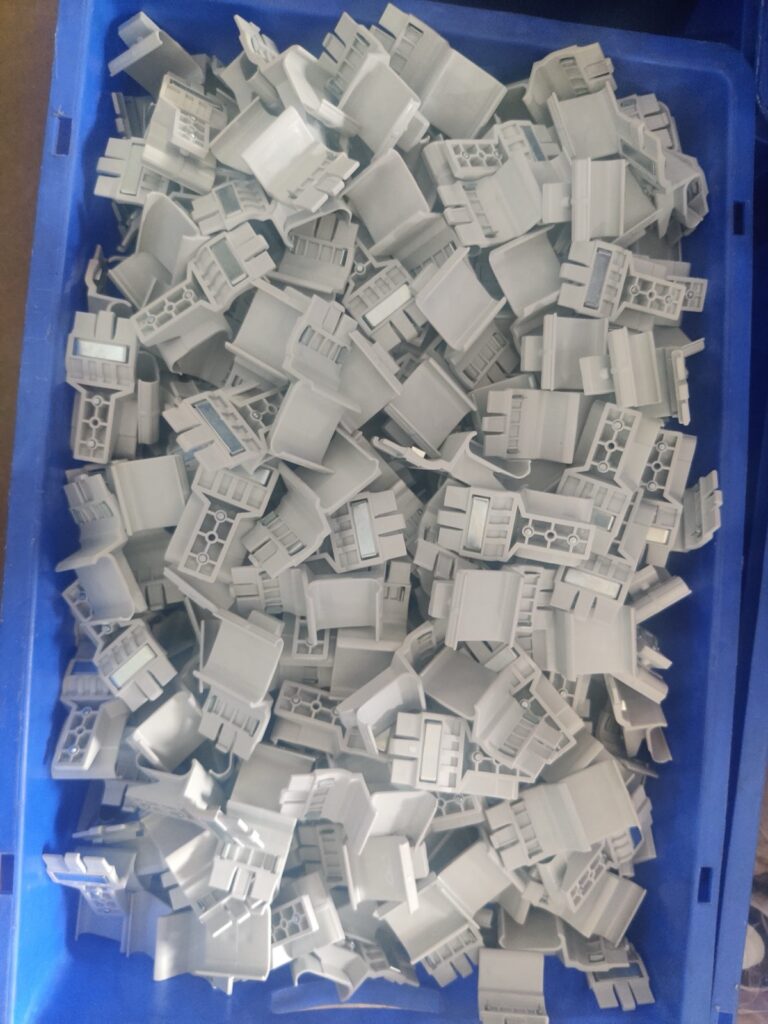

Plastics

Materials

1250 X 1250 MM

Within 10 microns

Engineering Plastics, Polyethylene, Polypropylene, Polyvinyl chloride, Polyethylene terephthalate, Bioplastics, etc.

Rubber

Materials

Natural rubber, Styrene-Butadiene Rubber, Nitrile Butadiene Rubber, Silicone Rubber, Fluorocarbon Rubber, Recycled Rubber, etc.

Heavy Fabrication

24000 MT/a

Materials

CS / MS, Alloy steel, Stainless Steel, etc.

Sheet Metal Fabrication

0.8 to 25 mm

Materials

Mild Steel, Stainless Steel, Aluminum, Brass, Copper, etc.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Global Sales Office

818, Preakness lane, Coppell, Texas, USA – 75019

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- Texas, USA