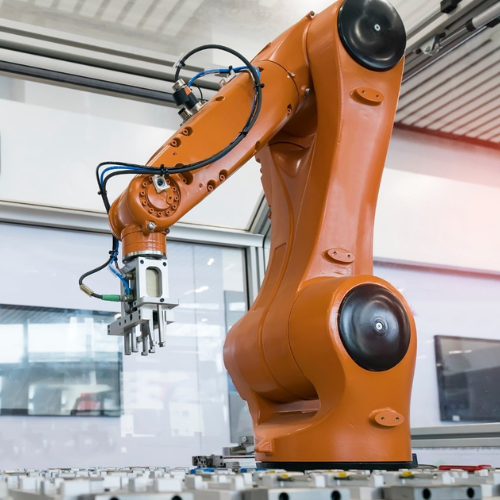

On-Demand Robotics Manufacturing for Rapid Innovation

Streamline and Accelerate Robotics Innovation with Rapid Prototyping and Scalable On-Demand Production.

Unleash Your Potential with Agile Manufacturing

Scalable Production

Flexible manufacturing supports smooth transitions from prototyping to mass production while maintaining precision, speed, and consistency.

Seamless Integration

Advanced machining ensures precise tolerances, material compatibility, and flawless fit for robotic assemblies within automation workflows.

Regulatory Assurance

Manufacturing meets ISO, AS9100, RoHS, and REACH standards, ensuring safety, reliability, and compliance for robotics across industries.

Our Clients

Accelerated Robotics Production

Advanced manufacturing processes significantly reduce lead times, ensuring rapid production of robotics components without compromising precision or quality.

Automated quoting systems and AI-driven manufacturing workflows optimize production planning, reducing administrative delays and speeding up production cycles.

Multi-axis CNC machining, high-speed milling, and precision die casting allows for faster material removal and shaping, minimizing production bottlenecks.

Rapid prototyping enables engineers to test and refine designs quickly, ensuring faster product development and deployment in robotics applications.

Ultra-Precise Component Tolerances

Precision machining and metrology-driven quality control maintain tight tolerances essential for high-performance robotics systems.

CNC machining and EDM processes achieve tolerances as tight as ±0.0002 inches, ensuring robotic components fit precisely and function reliably.

Advanced process control systems continuously monitor and adjust machining parameters to maintain uniform tolerances across all production batches.

High-precision components reduce mechanical backlash, improve actuator performance, and enhance accuracy in robotic movements, which are critical for automation and industrial applications.

Flexible On-Demand Manufacturing

Scalable manufacturing solutions provide flexibility for custom and repeatable parts, enhancing supply chain efficiency for robotics development.

For custom prototyping or mass production, flexible manufacturing methods accommodate various production scales while ensuring consistent quality.

Agile workflows enable rapid fulfillment of robotics parts, reducing downtime and eliminating excess inventory storage needs.

On-demand manufacturing supports iterative improvements, allowing engineers to refine and update designs without long delays or costly retooling.

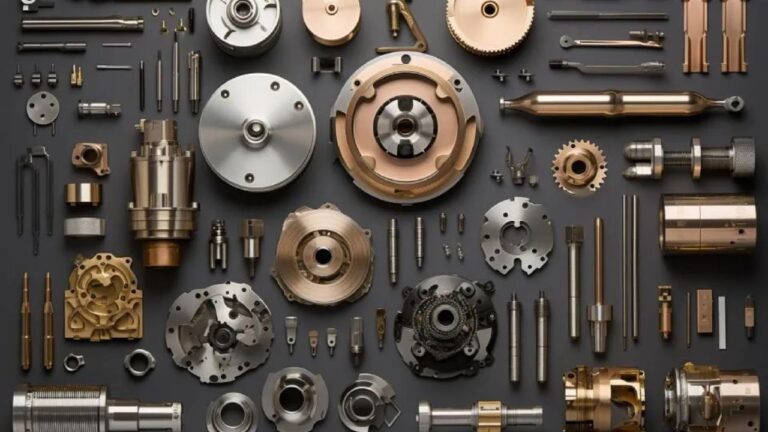

Our Robotics Products

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

Industries We Also Serve

Having Doubts? Our FAQ

Check all our Frequently Asked Question

Robotic automation ensures high-precision assembly of solar modules by using vision-guided pick-and-place systems, laser welding, and automated soldering. These systems maintain micron-level accuracy in cell alignment, busbar placement, and interconnection welding, reducing material defects and improving panel efficiency.

Automated robotic systems handle solar panel positioning, trenching for cabling, and mounting structures with GPS-guided precision. These robots improve installation speed, reduce labor dependency, and ensure accurate tilt angles for maximum energy capture, minimizing large-scale solar farm deployment errors.

Autonomous cleaning robots use AI-driven navigation, soft brushes, and waterless electrostatic cleaning methods to remove dust and debris from solar panels. This ensures maximum light absorption, enhances efficiency, and reduces maintenance costs, particularly in desert and high-dust environments.

AI-driven robotic inspection systems utilize infrared thermography, electroluminescence imaging, and high-speed defect detection to identify microcracks, delamination, and cell misalignment. Automated testing reduces human error, ensuring consistent quality control across large-scale solar panel production.

Scalable robotic manufacturing lines enable rapid production adjustments for varying panel sizes, materials, and configurations. With modular automation, manufacturers can switch between different panel designs without extensive retooling, ensuring flexibility in meeting market demands and new technological advancements.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany