Consumer Goods Manufacturing for Prototypes to Full-Scale Production

Optimize Product Development with High-Precision Rapid Prototyping and Scalable On-Demand Manufacturing.

Leading provider of high-quality, on-demand manufacturing solutions

Faster Time-to-Market

Accelerate production with rapid prototyping, automated machining, and real-time quality monitoring to reduce lead times efficiently.

Consistent Quality

Ensure uniform product integrity with AI-driven defect detection, non-destructive testing, and precision-controlled molding and casting techniques.

Cost-Effective Manufacturing

Minimize expenses with optimized material utilization, process automation, and energy-efficient manufacturing for cost-effective, high-volume production.

Our Clients

End-to-End Supply Chain Management

Simplify your supply chain with Frigate’s comprehensive management solutions. We leverage our global network of partners to source materials at competitive rates, manage inventory levels to avoid stockouts or overstocking, and oversee production to ensure on-time delivery. This allows you to focus on core competencies like design and engineering, while we handle the complexities of the supply chain.

Rapid Prototyping and Scalable Production

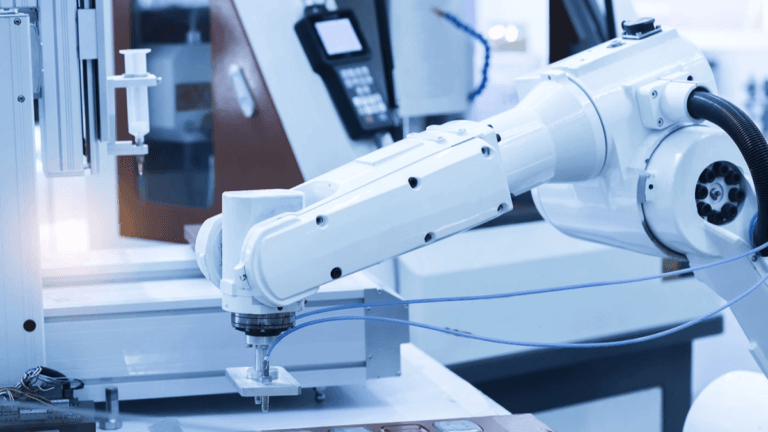

Efficient manufacturing processes enhance product development by reducing lead times, improving design flexibility, and ensuring high precision.

CNC machining with tolerances as tight as ±0.005”, injection molding with multi-cavity tooling, and industrial-grade 3D printing for rapid, accurate prototyping.

Scalable production capacities allow adjustments from 10 to 100,000+ units, supporting demand fluctuations without compromising quality.

Real-time monitoring, precision inspection, and AI-driven defect detection ensure over 99.8% dimensional accuracy across all production stages.

Low-volume production with Cost Optimization

Batch manufacturing strategies help reduce financial risk while maintaining product consistency and reliability for market-ready components.

Flexible production capabilities allow batch sizes starting from just 10 units, reducing upfront investment costs and excess inventory.

High-speed CNC machining and multi-stage molding reduce production cycles by 30-50%, improving efficiency and reducing material waste.

Advanced manufacturing ensures strong mechanical properties, precision tolerances within ±0.002”, and surface finish consistency for functional components.

High-Quality End-Use Parts

A broad selection of production-grade materials ensures compatibility with various applications, balancing strength, durability, and cost-effectiveness.

Injection molding supports over 100+ plastics, including ABS, Nylon, and PEEK, offering impact resistance, chemical stability, and flexibility.

CNC machining and 3D printing provide access to 40+ metals, including aluminum, stainless steel, and titanium, for lightweight, corrosion-resistant parts.

Material properties are tailored for tensile strength up to 150,000 psi, thermal resistance beyond 600°F, and precise dimensional accuracy.

Our Consumer Goods

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

Industries We Also Serve

Having Doubts? Our FAQ

Check all our Frequently Asked Question

Frigate employs 5-axis CNC machining, ultra-precision die casting, and laser micromachining to meet aerospace-level tolerances as tight as ±0.0005 inches. Advanced in-line metrology systems with laser interferometers and CMM inspection verify dimensions in real-time, ensuring compliance with AS9100 and NADCAP aerospace standards.

Frigate provides high-strength aluminum alloys (7075-T6, 6061-T6), titanium (Ti-6Al-4V), and Inconel (718, 625) for aerospace applications. PEEK, ULTEM 9085, and PPS composites are available for lightweight yet durable plastic components, offering flame resistance and high thermal stability up to 500°F (260°C).

Frigate uses finite element analysis (FEA) simulations, precision bonding techniques, and adaptive machining strategies to control thermal mismatch in hybrid material assemblies. Materials with similar coefficients of thermal expansion (CTE) are paired strategically, while cryogenic treatments and stress-relief annealing enhance dimensional stability.

Frigate utilizes Type III hard anodizing, electroless nickel plating, and PVD (physical vapor deposition) coatings to enhance wear resistance. Plasma electrolytic oxidation (PEO) is applied to aluminum components, providing superior hardness (HV 1500) and resistance to extreme aerospace conditions, including high-altitude oxidation.

Frigate integrates real-time CT scanning, ultrasonic non-destructive testing (NDT), and AI-driven defect detection to eliminate porosity and microstructural inconsistencies. Multi-axis robotic machining combined with automated adaptive tooling ensures precise geometries for complex, thin-walled structures with intricate undercuts and internal cavities.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany