- High-Performance

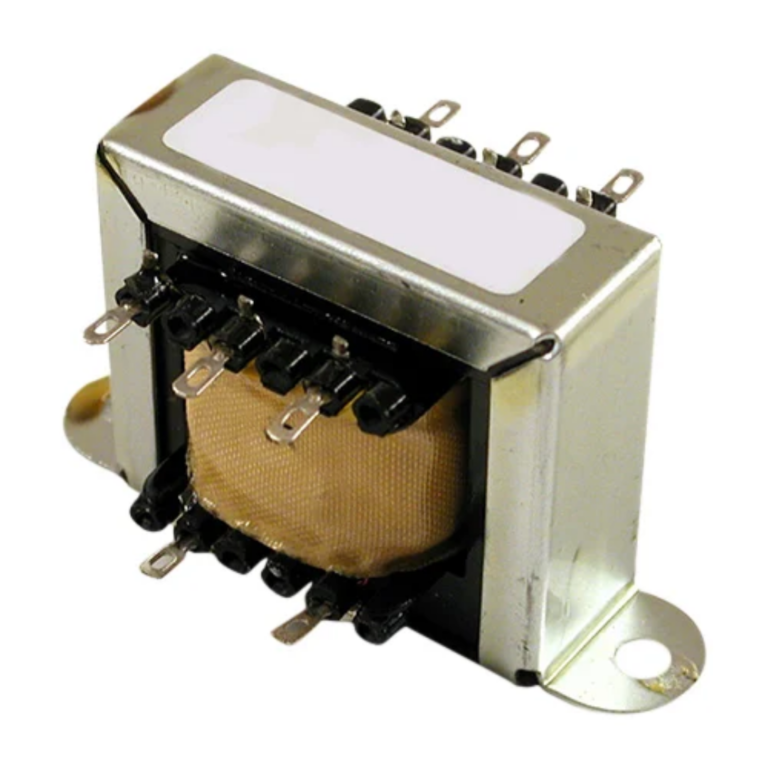

Specialty Application Transformers

Tailored energy solutions from Frigate’s specialty application transformers meet the unique demands of niche industrial setups. Built for precise applications, these units deliver steady performance in complex or unconventional systems.

Our Clients

Trusted by Engineers and Purchasing Leaders

- Versatile Offerings

Our Specialty Application Transformers Products

Explore our range of high-quality Specialty Application Transformers today.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

We export to 10+ countries

Frigate’s Global Presence

Frigate takes pride in facilitating “Make in India for the globe“. As our global network of Frigaters provides virtually limitless capacity, and through our IoT enabled platform your parts go directly into production. By digitally and technologically enabling “the silent pillars of the economy” MSME and SME manufacturing industries, we are able to tap the huge potential for manufacturing to bring the best results for our clients.

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

Industry Applications

Adjusts voltage for experimental solar or wind setups, ensuring steady output for precise data collection.

Delivers tailored energy to navigation and propulsion units, maintaining consistent function in salty, humid conditions.

Supplies safe, isolated energy for explosion-proof systems, supporting uniform operation in volatile zones.

Manages energy for high-fidelity amplifiers, providing steady performance for sound clarity.

Steps up or down voltages for satellite components, ensuring consistent energy in extreme environments.

Provides precise energy to monitoring devices, delivering uniform output in high-heat, corrosive settings.

- Optimized Efficiency

Resilient Industrial Power

Adjusting transformer specs to exact needs ensures steady performance for niche industrial demands without waste.

Offering custom configurations for unique setups delivers consistent energy across specialized systems seamlessly.

Using strong materials for harsh environments sustains uniform output with minimal upkeep in tough applications.

Specialty transformers from Frigate adjust core and winding configurations to meet unusual load demands effectively. This capability manages complex requirements like fluctuating currents or confined spaces with steady output. Such adaptability ensures consistent energy delivery where standard units underperform.

Isolated windings in Frigate’s specialty transformers prevent stray currents in sensitive setups. Strong insulation complements this feature by reducing hazards in volatile conditions like refineries or labs. Together, these elements sustain safe and steady performance under pressure.

Existing specialty transformer setups at Frigate modify swiftly to meet urgent custom needs. This streamlined process keeps costs manageable without sacrificing quality for smaller runs. That cost management delivers affordable, tailored solutions right on schedule.

Uniform quality in Frigate’s specialty transformers adapts seamlessly from prototype stages to full-scale production. Modular configurations allow adjustments in capacity or size as needs expand. These adjustments maintain steady energy flow as your project scales up.

Detailed specs for Frigate’s specialty transformers cover unique loads or harsh settings, simplifying your choice. Each option aligns with specific applications, such as audio precision or marine resilience. This clear alignment guides you to the best fit for your system’s needs.

- Engineering input to match electrical load, voltage, and space constraints.

- Custom winding and core geometry to fit specific system layouts.

- Adjustable mounting and connection options for seamless integration.

- Prototyping support to validate fit and performance before production.

- Moisture-sealed housings for marine or humid conditions.

- Heat-resistant insulation and thermal management systems.

- Corrosion-proof finishes for chemical or salty environments.

- Heavy-duty enclosures for shock, vibration, or dust exposure.

- Flexible production lines optimized for small to mid-volume orders.

- Modular component designs to reduce new tooling requirements.

- Efficient prototyping methods to speed up readiness.

- Strategic sourcing of materials to keep unit cost balanced.

- Precision voltage regulation for consistent output under varying loads.

- Low-noise coil winding for clean signal in audio and research gear.

- Shielded designs to reduce electromagnetic interference.

- Load balancing features to maintain stability during fluctuations.

- Scalable winding configurations to adjust capacity.

- Modular assemblies for quick swap or upgrade.

- Flexible core design to handle altered load demands.

- Built-in adaptability for evolving system requirements.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany