Is achieving product differentiation in a crowded market possible? Businesses today are under constant pressure to stand out, but true differentiation often feels out of reach. The challenge is balancing product uniqueness with efficient production, all while managing costs and meeting customer expectations. Many struggle with limited in-house capabilities and escalating costs, especially when trying to customize products for niche markets or rapidly shifting consumer demands. Contract manufacturing offers a solution, enabling companies to differentiate their products at scale while controlling costs and ensuring high-quality output.

The Drive for Product Differentiation in Competitive Markets

Today’s markets are crowded. It’s hard for products to stand out when dozens of competitors offer similar features. Research shows that over 70% of customers make purchasing decisions based on unique product features that appeal to their preferences. However, keeping up with these shifting preferences requires rapid production changes, which can be challenging without specialized infrastructure.

Adding to the difficulty is the need for technical precision. Differentiation is not only about aesthetic choices but also materials, functionality, and user experience. In-house production capabilities may lack the flexibility, technology, or skilled workforce required to adapt quickly. For instance, custom components often need unique materials or specialized machinery, which can be costly and time-consuming for companies without existing resources.

Scalability Challenges in Custom Manufacturing

When a business has a unique product design or custom feature in mind, scaling that idea becomes complex. Scaling up involves:

- Specialized infrastructure

- Adaptable production lines

- Efficient allocation of resources

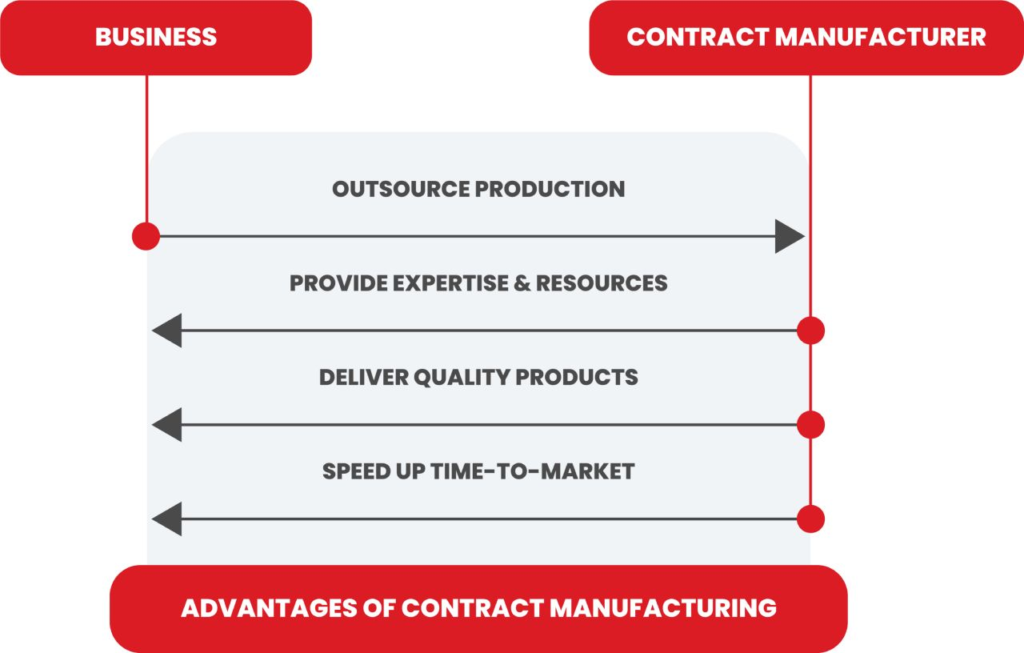

Suppose a company wants to produce a custom part in small batches. Traditional manufacturing processes usually focus on large batches to keep costs down. However, customization requires smaller runs, which can be expensive. Many businesses find that achieving product differentiation through custom manufacturing is prohibitively expensive due to the high costs of low-volume production. This is where contract manufacturing changes the game.

With contract manufacturing, companies can save up to 30% by outsourcing production to specialized facilities capable of small and large batch runs. Contract manufacturers use advanced machinery to handle varied specifications, making it possible to balance customization with cost efficiency.

Advantages of Contract Manufacturing for Customization at Scale

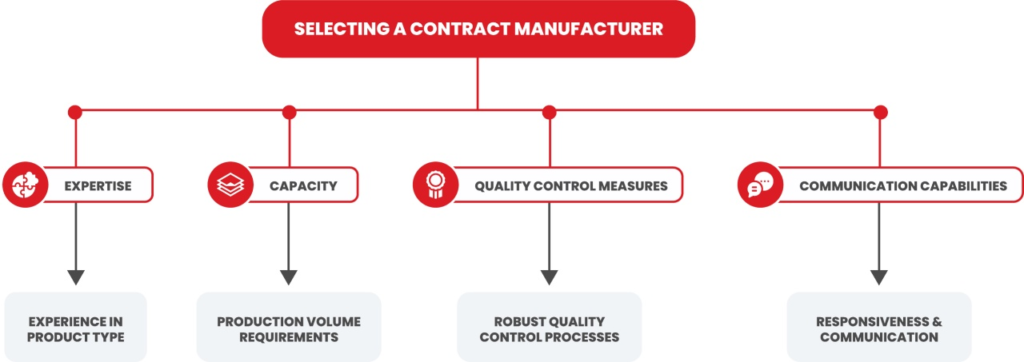

Contract manufacturing allows companies to access specialized technologies and expertise without large capital investments. This is especially valuable when creating differentiated products requiring advanced features. For example, producing high-strength aluminum alloys or highly detailed components requires machines like 5-axis CNC mills or precision injection molding. These machines are costly and require skilled operators to maintain high standards.

Companies don’t need to worry about acquiring or maintaining expensive machinery with a contract manufacturer. Contract manufacturers also provide experienced technicians who can run these machines efficiently, ensuring every customized product meets strict standards. Additionally, they have flexible production capabilities, so even when demand spikes, the manufacturer can meet the needs without compromising quality or speed.

Leveraging Advanced Technologies for Precision and Quality Control

In contract manufacturing, advanced technology ensures that customization does not compromise quality. Automation and robotics are at the core of modern manufacturing. Automated systems can produce parts with tight tolerances, ensuring every unit is nearly identical. This consistency is vital for high-quality product differentiation, especially those with complex designs.

Additionally, digital twin technology is widely used in contract manufacturing. A digital twin is a virtual model of the actual product that allows for simulation and testing before production starts. This is especially helpful for identifying potential issues early, reducing the risk of defects, and saving on costs associated with wasted materials. Digital twins also allow for adjustments to be made quickly, accommodating product differentiation requirements without major overhauls in the production line.

Statistics show that companies using digital twin technology can reduce production costs by 15-20% due to fewer errors and less rework. Rigorous testing protocols, often tailored to each client’s specific needs, further enhance quality control. Contract manufacturers may use non-destructive testing (NDT) methods, like X-ray or ultrasonic testing, to ensure internal integrity without damaging the product, making it possible to maintain high standards for customized components.

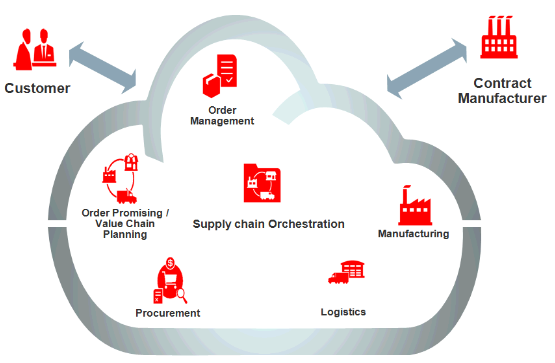

Streamlining Supply Chains for Custom Manufacturing

Custom manufacturing requires a well-coordinated supply chain. Sourcing materials for unique products can be difficult, particularly when specialty materials are needed. Contract manufacturers have established vendor relationships, allowing them to source rare or specialized materials quickly and cost-effectively. This reduces lead times and costs, making product differentiation feasible even for small-scale production runs.

An efficient supply chain also means less risk. Contract manufacturers often manage their logistics and warehousing, which minimizes overhead for their clients. Companies using contract manufacturing can avoid the burden of managing storage and reducing inventory-related expenses. For instance, a contract manufacturer with strong logistics capabilities can time shipments according to production needs, eliminating excess inventory and reducing associated costs by 10-15%.

Cost-Effectiveness and ROI Benefits of Contract Manufacturing

Cost savings is one of the greatest advantages of contract manufacturing for product differentiation. Companies avoid the heavy expenses of buying and maintaining specialized equipment. Instead, they benefit from predictable pricing models, which make budgeting easier. For example, the cost of setting up a high-precision production line can range from $100,000 to over $500,000, depending on the technology required. Contract manufacturing offers an alternative: companies can pay per unit or batch rather than invest large sums upfront.

Furthermore, outsourcing to a contract manufacturer can improve time-to-market. By leveraging the manufacturer’s existing infrastructure, companies can move faster from prototype to production, driving a better return on investment. Studies show that businesses that can launch products quickly achieve a 35% higher ROI compared to slower-moving competitors. This speed-to-market benefit is crucial in competitive industries where innovation and responsiveness are essential for maintaining market position.

Quality Assurance and Regulatory Compliance Support

Quality assurance is a top priority, especially for products requiring tight tolerances or specific standards. Contract manufacturers adhere to industry regulations and maintain certifications relevant to aerospace (AS9100) or automotive (IATF 16949) sectors. These certifications ensure that every part or product meets required quality and safety standards, protecting the brand’s reputation and maintaining customer trust.

Contract manufacturers streamline the certification process. For example, if a client needs to comply with FDA standards for medical devices, the contract manufacturer can handle the necessary audits, tests, and documentation. This reduces the client’s burden, saving time and resources. By working with contract manufacturers, businesses can access expertise in regulatory compliance, knowing that each product differentiation will meet high standards without strained internal resources.

Driving Excellence in Custom Manufacturing with Frigate

Regarding achieving product differentiation at scale, Frigate offers a wealth of specialized capabilities that set us apart. Our commitment to precision, flexibility, and customer-centric manufacturing solutions enables businesses to confidently bring innovative products to market. We work with diverse industries, including automotive, aerospace, medical, and consumer electronics, providing expert manufacturing tailored to each sector’s unique demands. Here’s how Frigate can help your business achieve seamless, scalable customization:

- Advanced Technology and Equipment—Frigate’s facilities are equipped with state-of-the-art technologies, including 5-axis CNC machining, robotic automation, and digital twin simulations. This advanced infrastructure allows us to efficiently handle complex geometries, high-precision components, and low—to high-volume production runs.

- Expertise in Materials and Processes – Our team brings deep expertise in a wide range of materials—from high-strength metals like aluminum and titanium to specialized plastics and composites. Whether you require die-casting, precision stamping, or injection molding, Frigate ensures that each product differentiation meets your unique material and functional specifications.

- Dedicated Quality Assurance – Quality is at the core of everything we do. Frigate maintains stringent quality control processes, leveraging non-destructive testing (NDT), in-line inspections, and ISO-certified protocols to ensure that every product differentiation meets the highest standards. Our team is skilled in compliance requirements across industries, helping clients meet regulatory standards without additional hassle.

- Supply Chain Integration and Cost Efficiency – Frigate’s well-established supply chain enables us to source materials quickly and efficiently, reducing lead times and costs for our clients. We also manage logistics and warehousing, which means clients can rely on a smooth, end-to-end production process that aligns with their schedules and budgets.

- Customized Solutions at Scale – At Frigate, we recognize that every client’s needs are unique. Our flexible production lines are designed to handle varied batch sizes, from prototypes to full-scale production, enabling seamless scalability as your business grows. Whether you’re refining a niche product or scaling up for broader distribution, Frigate’s customized approach supports your product differentiation goals.

By partnering with Frigate, businesses can access a reliable, resource-rich manufacturing partner that adapts to evolving market demands and technological advancements, ensuring your products stay competitive and innovative.

Conclusion

Achieving product differentiation doesn’t have to mean taking on the full weight of manufacturing in-house. Contract manufacturing provides an effective, scalable, and cost-efficient way to produce unique products that meet high standards while adapting to changing consumer demands. It is a powerful tool for companies looking to stand out in competitive markets, with benefits like access to specialized technology, streamlined supply chains, and robust quality assurance.

Ready to explore how contract manufacturing can bring your unique product ideas to life? Contact Frigate today for a consultation on customized manufacturing solutions enabling scale product differentiation. We’re here to help turn your product differentiation visions into reality.