For organizations managing critical infrastructure, fire risk is a matter of safety and operational resilience. The risks associated with electrical fires, especially in high-value sectors such as energy, telecom, and data centers, are substantial. Loss of service, significant downtime, regulatory fines, and potential liabilities make fire-resistant cables a strategic necessity.

But how do fire-resistant cables contribute to a company’s long-term operational success? Can they improve compliance, reduce risk exposure, and ensure business continuity while adhering to industry standards? Understanding these factors will enable companies to make informed, risk-mitigated decisions regarding their fire protection systems.

Why Are Regulatory Compliance and Safety Standards Crucial for Fire-Resistant Cables?

One of the most pressing concerns for organizations overseeing critical infrastructure is ensuring regulatory compliance. Compliance isn’t just about avoiding penalties; it’s about establishing a culture of safety and resilience. Fire-resistant cables are integral to meeting these regulatory frameworks.

Key Regulatory Requirements

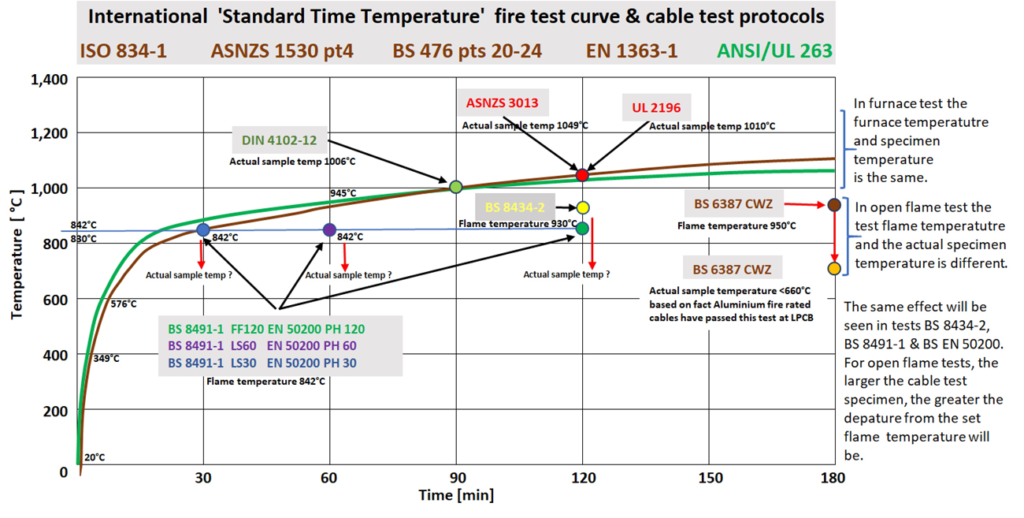

International standards such as IEC 60332, BS 6387, and UL 1424 outline fire-resistant cable performance requirements. These standards test cables for fire resistance, heat endurance, and continued operation under stress conditions. For instance –

- IEC 60332 evaluates flame propagation.

- BS 6387 tests cables under fire, mechanical impact, and water exposure.

- UL 1424 focuses on resistance to fire in electrical and control cables.

Organizations that fail to meet these standards can face severe penalties, higher insurance premiums, and the risk of losing operational licenses, particularly in critical sectors like energy generation, transportation, and telecommunications.

Regulatory Implications on Corporate Strategy

With a growing global emphasis on fire safety standards, businesses are held accountable for their internal operations and supply chains. The inability to meet fire-resistant cable standards could expose companies to regulatory scrutiny. Moreover, global compliance pressures like those in Europe, North America, and Asia-Pacific require businesses to remain agile and proactive in their fire safety investments.

Impact on Risk Management and Insurance Costs

Adhering to fire-resistant cable standards can significantly reduce insurance premiums for businesses, especially in high-risk industries such as energy, telecommunications, and manufacturing. Insurance companies assess the risk of fire-related damage when calculating premiums, and using certified fire-resistant cables reduces the likelihood of claims and damages, resulting in lower operational costs over time.

Improving Supply Chain Integrity and Vendor Compliance

Ensuring all vendors adhere to fire safety regulations is critical for organizations managing global supply chains. Fire-resistant cables from compliant manufacturers are essential for maintaining supply chain integrity, particularly in sectors like aerospace and automotive, where high standards are enforced. Failing to use approved materials could lead to delays, disruption, or loss of supplier contracts, undermining the organization’s overall operational efficiency and credibility.

How Do Fire-Resistant Cables Contribute to Operational Resilience and Business Continuity?

The reliability of critical systems during a fire emergency is the cornerstone of business continuity. A fire-resistant cable is essential for keeping mission-critical infrastructure running while minimizing a fire’s financial and operational impact.

Ensuring Continuous Operation

In sectors such as telecommunications, data centers, and power plants, where uptime is paramount, the uninterrupted function of electrical systems is non-negotiable. Fire-resistant cables provide electrical circuits that operate during high temperatures, preventing service outages, system failures, and catastrophic data losses.

For instance, in a data center, even a few minutes of power loss could cause irreparable damage to sensitive equipment and systems, potentially causing millions in revenue loss. Fire-resistant cables ensure that emergency backup systems, fire alarms, and critical HVAC systems remain operational, minimizing the risk of business disruption.

Risk Mitigation and Cost Control

Fire-related damage to assets is expensive. The total economic impact of fire incidents includes direct damage, downtime costs, operational inefficiencies, and long-term reputational damage. The average cost of a business interruption due to a fire incident can amount to millions of dollars. These costs are amplified in industries with high operational costs, like manufacturing, chemical processing, and oil and gas.

Investing in fire-resistant cables is, therefore, a risk-mitigation strategy. While the initial investment might be higher, the ROI in terms of avoided downtime, minimized damage, and reduced operational disruptions is significant. The long-term value far outweighs the initial cost when considering the potential for lost revenue, operational continuity, and brand integrity.

Ensuring Safety for Personnel and Minimizing Liability

In addition to protecting infrastructure, fire-resistant cables play a critical role in safeguarding personnel. The risk of fire-related injuries or fatalities is significant in industries such as oil and gas, chemical processing, and manufacturing. Fire-resistant cables are designed to maintain their function even in extreme heat, enabling vital safety systems such as emergency alarms, evacuation systems, and firefighting equipment to remain operational during a fire.

What Are the Advances in Materials and Testing Methods for Fire-Resistant Cables?

The continuous evolution of cable materials and testing methodologies directly impacts the performance and efficiency of fire-resistant cables. Technological advancements have led to the development of superior materials and improved testing methods, providing better protection and performance under extreme conditions.

Innovative Materials for Enhanced Fire Resistance

- Halogen-Free Materials – Cables manufactured using LSZH (Low Smoke Zero Halogen) materials are increasingly used in high-risk applications because they minimize toxic gas emissions during combustion. These cables are safer in environments where human exposure to smoke can have lethal effects.

- Thermoplastic Elastomers (TPE) – TPE-based fire-resistant cables provide higher mechanical strength and excellent flexibility, ensuring better performance under harsh conditions like extreme temperatures and physical stress.

- Fire-Resistant Insulation Technologies – Enhanced fire-resistant polymeric insulations ensure that cables can continue functioning at high temperatures (up to 1,000°C), which is critical for emergency response systems where power must remain uninterrupted.

Testing and Validation Protocols

The testing of fire-resistant cables is becoming more stringent as fire safety expectations grow. Beyond traditional flame propagation tests, manufacturers are now required to ensure that cables –

- Withstand mechanical stress during fire scenarios (e.g., BS 6387)

- Function continuously for a defined period under fire exposure

- Do not contribute to toxic gas buildup in confined spaces (critical for underground networks and subway systems)

Emerging testing methods now include real-time fire simulations replicating complex fire scenarios, offering a more accurate representation of cable performance in real-world conditions.

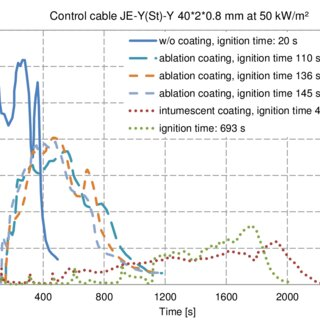

Advanced Fire-Resistant Coatings for Increased Durability

Recent developments in intumescent coatings and ceramic-based fire barriers have improved cable fire resistance. These advanced coatings expand when exposed to heat, forming a protective layer that insulates the cable core and prevents damage. Such coatings provide exceptional resistance to prolonged fire exposure, even at elevated temperatures, and are especially useful in high-risk environments like petrochemical plants and power substations.

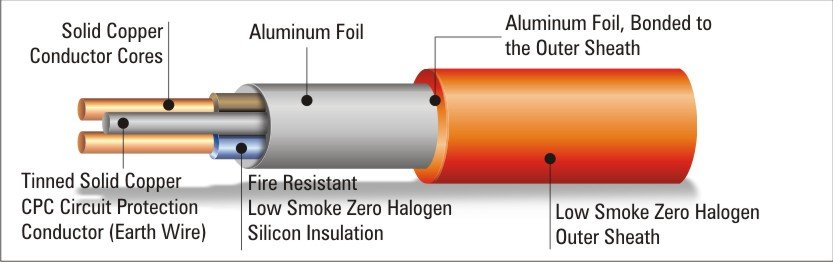

Improved Cable Shielding for Enhanced Performance Under Stress

In addition to the fire-resistant insulation, advanced shielding materials have improved cable performance in fire scenarios. Metallic shields, such as those made from aluminum or copper, offer superior protection against electrical and thermal stresses, ensuring the cables can continue transmitting signals or power even in extreme fire conditions. This improvement in shielding technology makes fire-resistant cables more robust, ensuring they meet the demanding requirements of modern industrial applications.

How Can Companies Achieve Cost Efficiency Through Strategic Procurement of Fire-Resistant Cables?

Strategic procurement of fire-resistant cables is essential for maximizing the long-term benefits of cable performance while minimizing upfront costs. Companies need to balance quality, compliance, and cost-efficiency.

Optimizing Procurement Strategies

Regarding procurement, selecting high-quality fire-resistant cables may involve higher initial costs. However, this is offset by reduced potential losses from operational downtime, fines for non-compliance, and damage from fire-related incidents. Bulk purchasing agreements or long-term contracts with suppliers who offer volume discounts can help mitigate the higher upfront investment.

Additionally, leveraging supply chain optimization techniques and adopting just-in-time delivery systems can help reduce holding costs while ensuring cables are available without overstocking.

Vendor Risk Management and Selection

Vendor selection is a strategic decision directly affecting a company’s operational risk. When sourcing fire-resistant cables, companies must ensure that the supplier meets international compliance certifications and adheres to quality assurance practices. Suppliers should also have a proven track record in providing solutions for mission-critical infrastructure in high-risk industries.

Leveraging Total Cost of Ownership (TCO) Analysis

Instead of focusing only on initial costs, companies should evaluate the Total Cost of Ownership (TCO), considering installation, maintenance, and lifespan. Fire-resistant cables requiring less upkeep and lasting longer can offer better long-term value, even with higher upfront costs.

Integration of Fire-Resistant Cables in Design and Planning Stages

Incorporating fire-resistant cables early in the design phase helps avoid costly retrofitting later. This proactive approach can also improve procurement terms and overall system reliability, resulting in cost savings and smoother project execution.

How Does Frigate’s Fire-Resistant Cable Technology Ensure Long-Term Operational Continuity?

Frigate stands out for its advanced fire-resistant cable manufacturing capabilities, ensuring that cables are engineered to meet the most demanding operational and safety requirements.

Advanced Material Selection and Engineering

Frigate utilizes specialized, high-performance materials such as LSZH (Low Smoke Zero Halogen) and thermoplastic elastomers (TPE), which offer superior fire resistance and mechanical strength. These materials are carefully chosen for each application based on fire performance, flexibility, and temperature tolerance. This ensures that cables perform reliably in extreme conditions while minimizing toxic smoke emissions in confined spaces.

Precision Cable Design and Customization

Frigate’s team applies advanced computer-aided design (CAD) and finite element analysis (FEA) techniques to precisely model fire-resistant cables. This enables the creation of customized solutions that meet specific industry needs—whether for telecommunications in urban environments, data centers with high uptime requirements, or power plants needing cables that perform under extreme temperature and mechanical stress.

Rigorous Testing with Real-Time Fire Simulations

Frigate’s testing procedures go beyond traditional flame propagation tests. The company employs real-time fire simulations replicating complex, high-stress fire scenarios, such as those encountered in subway systems, offshore rigs, and nuclear power plants. These simulations assess the resistance to flame and the cable’s ability to maintain electrical conductivity and mechanical integrity under severe fire conditions for extended periods.

Compliance with Industry-Specific Fire Safety Standards

Frigate’s fire-resistant cables are meticulously engineered to comply with a wide range of global standards, including IEC 60332, BS 6387, and UL 1424, as well as country-specific regulations like NFPA and NEC. Frigate ensures that each cable meets these standards and undergoes multi-parameter testing that considers environmental stresses such as water exposure, mechanical impact, and temperature extremes, ensuring consistent performance in real-world conditions.

Enhanced Durability with Multi-Layer Insulation and Shielding

Frigate enhances fire-resistant cable performance by using multi-layered insulation and shielding, including ceramic-based and intumescent coatings. These layers provide insulation against high-temperature environments, prevent short-circuiting, and significantly extend the cable’s operational life even under fire conditions. This approach ensures that critical electrical circuits, control systems, and safety equipment remain operational during an emergency.

Conclusion

Fire incidents have the potential to disrupt operations and incur substantial costs. Fire-resistant cables provide a cost-effective solution to minimize risk exposure while ensuring that critical systems remain operational during emergencies. Frigate offers industry-leading fire-resistant cable solutions, delivering the performance, compliance, and peace of mind that businesses need to protect their infrastructure and maintain operational integrity.

Contact us today for more information on how Frigate can support your business with high-performance, fire-resistant cables!