Industry Speciality Cables

The integrity of your cables is crucial when operating in high-temperature environments. Our cables are manufactured with high-performance thermoplastic and thermoset materials designed to withstand temperatures up to 250°C or higher. These materials provide excellent resistance to thermal degradation, preventing cable insulation from breaking down in extreme conditions. Our cables are ideal for power generation plants, furnaces, and high-heat manufacturing processes, offering uninterrupted performance and preventing costly breakdowns.

Our Industry Speciality Cables

Explore our range of high-quality cable solutions today.

Our Clients

Technical Advantages

Safety is a top priority in construction, transportation, and aerospace industries, where cables are exposed to fire risks. Our cables feature flame-retardant properties, meeting or exceeding international standards like UL 1581 and IEC 60332. Additionally, they are engineered to produce minimal smoke and low toxicity in the event of a fire, meeting stringent safety requirements for fire safety in public spaces, industrial plants, and transportation networks. These features ensure that your cables not only perform under extreme conditions but also protect workers and assets in case of an emergency.

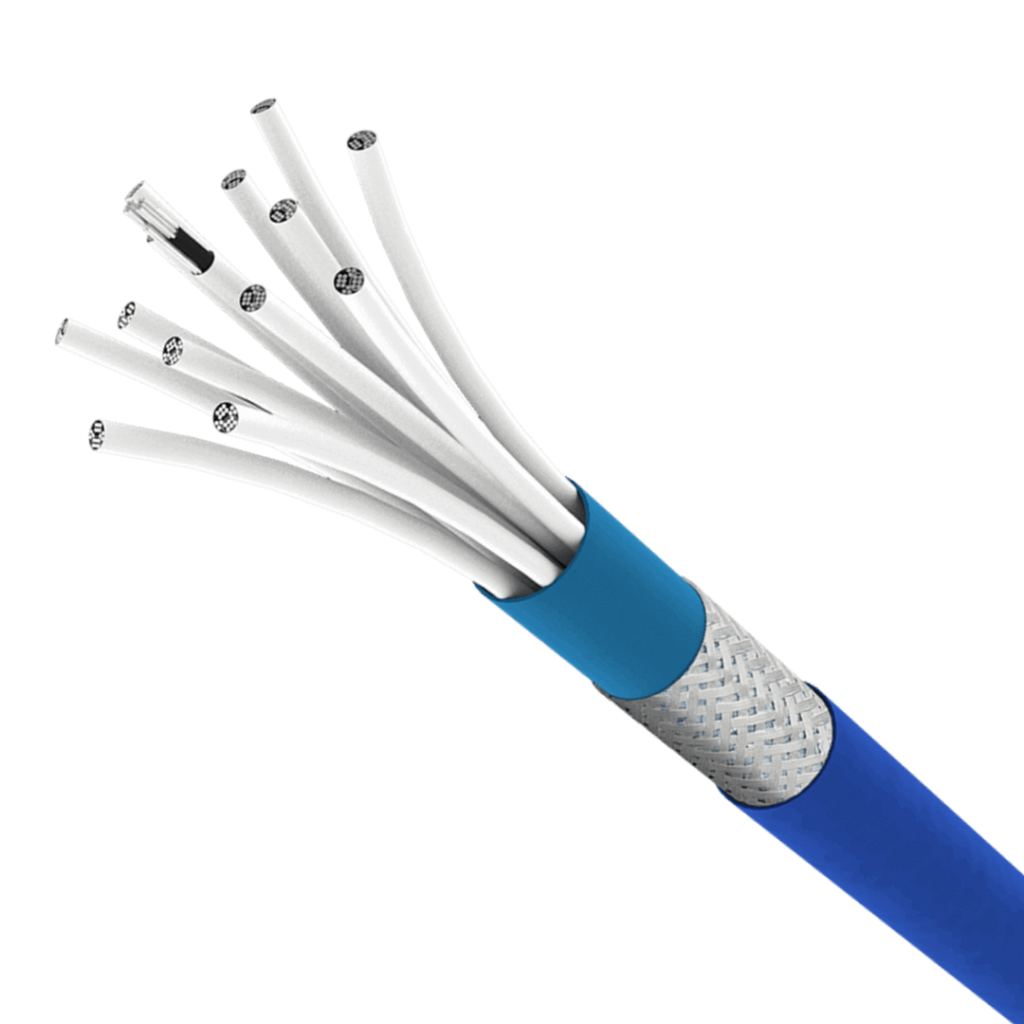

In robotics and automotive applications, cables must maintain flexibility while enduring constant bending, twisting, and movement. Our cables are designed with specialized flexible insulation and strengthened conductors, allowing them to withstand high mechanical stress without losing functionality. This is achieved by using braided steel wires or aramid fibers within the cable construction, ensuring the cable retains its flexibility and durability for long-term use in dynamic environments.

Customized Cable Construction for Specific Applications

We offer fully customized cable solutions because off-the-shelf cables may not always meet your exact requirements. To address your needs, we can design cables with specific conductor configurations (e.g., multi-conductor, single-conductor), unique shielding types, and specialized coatings. Whether you need cables for subsea installations, aerospace applications, or high-speed rail systems, we work with you to create cables that fit your precise operational needs, improving performance and minimizing risk.

While the initial cost of cables is a key consideration, the total cost of ownership often involves ongoing maintenance, repairs, and replacements. Our specialty cables are engineered for maximum reliability, offering an extended lifespan in high-stress applications. By utilizing high-quality materials, such as high-purity copper, advanced polymers, and corrosion-resistant alloys, our cables reduce the need for frequent replacements and maintenance, leading to lower overall operating costs and improved ROI.

Industry Applications

High-pressure, corrosion-resistant cables for subsea communication and power transmission in underwater and offshore oil platforms.

Radiation-resistant cables designed for long-term reliability and safety in nuclear reactors and waste management facilities.

High-flex cables for dynamic motion in rail signaling systems and automotive powertrain and safety systems.

Biocompatible cables with low-voltage insulation for critical medical devices, ensuring electrical safety in patient care environments.

Abrasion-resistant, flame-retardant cables for underground mining operations, resistant to chemical exposure and extreme mechanical stress.

Cables engineered for high-temperature and high-voltage heating, ventilation, and air conditioning applications.

Having Doubts? Our FAQ

Check all our Frequently Asked Question

Cables for renewable energy applications, like solar and wind, utilize UV-resistant coatings and weatherproof jacketing materials such as UV-stabilized polyolefin or EPDM rubber. These materials protect the cable from degradation caused by prolonged sun exposure, extreme temperatures, and harsh environmental conditions.

Dielectric strength is critical in high-voltage cables to prevent electrical breakdown. Specialty cables for high-voltage transmission use high-quality insulation materials like cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR), which provide superior dielectric strength and allow safe operation under high electrical stress.

Flexible cables in industrial automation are designed with robust, multi-strand conductors and high-flex insulation materials, such as TPE or PVC. These cables incorporate reinforcing fibers or braided steel for enhanced mechanical strength, allowing them to endure constant bending, twisting, and movement without compromising electrical performance.

Multi-layer shielding, including aluminum foil, copper braiding, and conductive PVC, prevents external electromagnetic interference (EMI) and internal signal crosstalk. This ensures high integrity of data signals, particularly in applications requiring real-time data transmission, such as medical devices, automation systems, and aerospace communications.

Fire-resistant cables are designed with halogen-free, flame-retardant coatings that prevent the spread of fire while maintaining electrical functionality. These cables meet stringent fire safety standards such as IEC 60332 and UL 1581, ensuring safe operation in high-risk environments like power plants, tunnels, and high-rise buildings.

- Design conductors with precise cross-sectional area to minimize Joule heating.

- Use high-purity copper or aluminum to enhance electrical conductivity.

- Implement multi-strand or Litz wire configurations to reduce skin effect at high frequencies.

- Optimize insulation thickness for maximum dielectric stability under load.

- Incorporate specialized shielding to prevent electromagnetic interference (EMI) and energy losses.

- Reinforce conductors with braided steel, aramid fibers, or flexible alloy cores.

- Use thermoplastic elastomers, silicone, or TPE for high-flex insulation.

- Layer jacketing and braiding to resist crushing, abrasion, and repeated bending.

- Optimize strand geometry to prevent conductor fatigue over millions of bending cycles.

- Design strain relief at termination points to prevent mechanical failure.

- Support single-core, multi-core, twisted pair, coaxial, and shielded multi-layer configurations.

- Control conductor twisting, spacing, and insulation to reduce crosstalk and signal loss.

- Optimize shielding with foil, braid, or combined layers for specific EMI/RFI conditions.

- Allow precise conductor sizing from 0.5 mm² to 1000 mm² for voltage/current optimization.

- Engineer cable geometry for thermal and electrical load balancing across cores.

- Use advanced thermoset or thermoplastic insulation capable of 250°C+ continuous operation.

- Reinforce critical areas with aramid or steel fibers to maintain structural integrity.

- Optimize conductor configuration to minimize heat concentration.

- Use layered jacketing to improve heat dissipation and mechanical stability.

- Balance flexibility and thermal resistance for dynamic high-temperature environments.

- Use precision conductor geometry to reduce inductive and capacitive losses.

- Implement controlled impedance via specific core arrangements and insulation thickness.

- Apply multi-layer shielding with foil and braid to eliminate EMI and crosstalk.

- Select conductor materials to maintain low resistance and stable performance at high frequencies.

- Customize jacket and insulation dielectric properties to preserve signal integrity.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany