Precision machining thrives on precision planning. While CNC machines are capable of incredible accuracy, they rely entirely on the quality of the engineering drawings provided. Yet, across industries, many cost overruns in CNC manufacturing can be traced back to CNC drawing mistakes. These errors—from minor tolerance missteps to complete design-for-manufacturing mismatches—introduce inefficiencies that scale with volume.

In a market where production speed, cost control, and part quality must coexist, the cost of a flawed drawing can be substantial. Studies reveal that nearly 20% of CNC production issues stem directly from drawing misinterpretations or oversights. Minimizing these CNC drawing mistakes is crucial for procurement and manufacturing teams operating under tight timelines and strict budgetary oversight.

The following sections explore CNC drawings’ most common technical issues and outline how Frigate resolves them through proactive engineering and advanced digital validation.

What Are CNC Drawing Mistakes That Increase Production Cost & Their Solutions?

Every part starts with a drawing. If that drawing has errors—like unclear tolerances, hard-to-reach features, or conflicting dimensions—it can slow down production, increase scrap, and raise machining costs.

Even small issues can cause delays, tooling problems, or setup changes. Studies show that up to 30% of total machining cost often comes from CNC drawing mistakes.

Frigate reduces this risk by running every file through an advanced DFM system. It finds errors early and suggests fixes before machining starts.

Here are 10 CNC drawing mistakes that increase production cost—and how Frigate solves them.

Geometry That Exceeds Machining Constraints

Engineering drawings often include design features such as deep internal cavities, undercuts, sharp internal corners, and ultra-thin walls that exceed standard machinability thresholds. These features may not be feasible within the limitations of conventional 3-axis or even 5-axis CNC systems.

Why It Increases Cost – These complex geometries demand specialized tooling, extended machine programming, custom workholding, and additional setups. Non-standard features also increase the probability of deflection, vibration, and tool failure, reducing throughput and increasing the risk of nonconformity.

Frigate’s Solution – Frigate utilizes high-fidelity Design for Manufacturability (DFM) analysis tools that assess the part’s features against machine kinematics and tool accessibility parameters. Geometries that require deviation from standard tooling strategies are flagged early. Engineers then provide optimized design alternatives that align with cost-effective CNC capabilities while preserving functional intent.

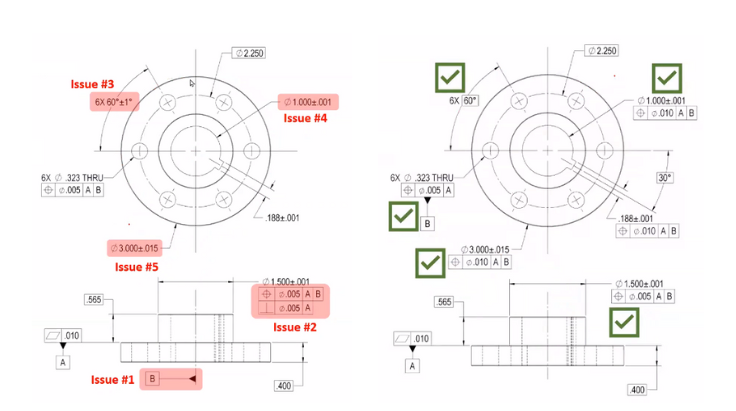

Non-Standardized Drawing Conventions

Another one of the CNC drawing mistakes that lack dimensional uniformity include inconsistent tolerancing schemes or omit critical GD&T (Geometric Dimensioning & Tolerancing) annotations that disrupt production flow. Unlabeled datums, ambiguous reference planes, and undocumented critical features are common sources of misinterpretation.

Why It Increases Cost – Misaligned conventions force CNC programmers and QA inspectors to make assumptions, leading to programming errors, quality escapes, or rejected first articles. These missteps escalate non-value-added engineering hours and downstream rework.

Frigate’s Solution – All client drawings are processed through Frigate’s drawing validation engine, which enforces adherence to ISO 2768, ASME Y14.5, and other global drawing standards. The system auto-corrects annotation style, detects omission of critical control features, and ensures interoperability between CAD/CAM and CMM inspection systems—reducing ambiguity from design to inspection.

Overuse of Tight Tolerances

Applying unnecessarily tight tolerances (e.g., ±0.01 mm) across an entire drawing rather than targeting them only on function-critical areas which considered as one of the major CNC drawing mistakes.

Why It Increases Cost – Precision machining at ultra-tight tolerances reduces allowable feed rates and tool life while increasing cycle time. It also requires frequent tool offset checks and drives up metrology complexity with CMM or optical inspection.

Frigate’s Solution – Frigate leverages a tolerance rationalization workflow based on critical-to-function (CTF) analysis. Tolerance schemes are matched with part interfaces and performance zones, relaxing non-critical features. This enables high-speed machining where feasible while preserving dimensional control optimizing cost, quality, and time.

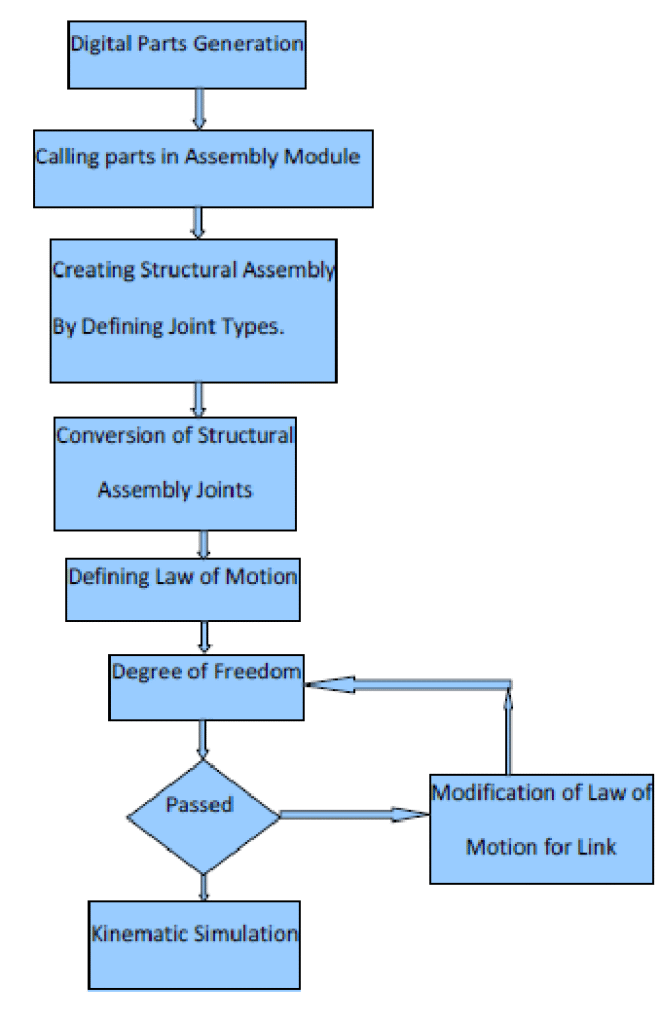

Inadequate Machining Orientation Planning

Engineering drawings that ignore optimal part orientation for CNC machining often lead to inaccessible features or inefficient material removal paths. Poor fixture consideration can compromise structural stability during roughing or finishing operations because of CNC drawing mistakes.

Why It Increases Cost – Suboptimal orientation increases the number of required setups, raises fixture complexity, and introduces positional inaccuracies during refixturing. It can also increase tool overhang, causing vibration and deflection.

Frigate’s Solution – Frigate performs kinematic simulations and fixture design validation at the quotation stage. The system auto-generates recommended stock orientations, evaluates surface accessibility per setup, and suggests orientation-driven design adjustments that enable single-setup machining wherever possible. This reduces both time and risk of non-repeatability.

Inaccessible Tool Paths

Features like narrow grooves, deep blind holes, or sharp internal corners are often drawn without verifying end mill access, approach angles, or minimum tool diameters which is notable, one of the CNC drawing mistakes.

Why It Increases Cost – These toolpath obstructions require custom tools, reduced cutting depths, or unconventional multi-axis entry strategies. They increase programming time and lead to higher tool deflection and wear.

Frigate’s Solution – Frigate uses tool reach simulations that simulate cutter geometry against every feature surface. If feature geometry exceeds standard cutter accessibility, engineers recommend tool-friendly alternatives such as open-ended features, minimum internal radii, or split geometries to eliminate obstructions without compromising function.

Impractical Surface Finish Specifications

Specifying extremely fine surface finishes (e.g., Ra 0.2–0.4 µm) across large surfaces or on low-stress components that do not demand high smoothness.

Why It Increases Cost – Ultra-fine finishes require low feed rates, multiple tool passes, or secondary finishing processes such as grinding or lapping. These operations dramatically increase machine time cost per unit and often require post-CNC validation.

Frigate’s Solution – Frigate cross-validates surface finish requirements against material machinability indexes and functional surface criteria (e.g., sealing, sliding, mating). Where over-specification is detected, the finish callouts are revised using cost-benefit modeling. This helps balance aesthetics and performance without adding unnecessary finishing operations.

Conflicting 2D and 3D Data

Incongruencies between 2D drawings and 3D CAD models—such as mismatched dimensions, feature omission, or outdated revisions—can derail the programming process and increase error rates due to CNC drawing mistakes.

Why It Increases Cost – CAM engineers may rely on the wrong data set, leading to incorrect toolpaths, improper tolerances, and scrap parts. The verification burden also slows down project onboarding.

Frigate’s Solution – Frigate executes a model-to-drawing validation protocol using parametric data comparison tools. Any variation in dimensional fidelity or tolerance hierarchy between 2D and 3D data is flagged and resolved before NC code generation. This ensures the digital twin is accurate and consistent across production stages.

Unclear Fit Definitions for Mating Parts

Omitting critical fit designations (such as clearance, interference, or transition fits) or failing to specify ISO fit standards (e.g., H7/g6) for mating features.

Why It Increases Cost – The absence of fit specifications leads to incompatible part assemblies, post-machining adjustments, or scrapped assemblies due to misaligned tolerance stacks.

Frigate’s Solution – Frigate runs fit logic validation based on functional relationships during drawing intake. Tolerance stack-ups are analyzed using Monte Carlo simulations, and precise ISO fits are recommended or corrected on all interdependent features—ensuring robust assembly and minimized in-field failure risk.

Selection of Poorly Machinable Materials

Choosing exotic alloys such as Inconel, Monel, or Hastelloy for parts that do not require extreme thermal or corrosion resistance.

Why It Increases Cost – These materials have low machinability ratings, causing excessive tool wear, slower feed rates, high-temperature chip evacuation challenges, and increased tooling costs.

Frigate’s Solution – Frigate uses a material selection matrix that considers mechanical performance, thermal conductivity, machinability index, and total cost of ownership. If equivalent mechanical properties can be achieved using machinable alternatives like 6061-T6 or 4140, recommendations are made to reduce runtime and tool consumption without compromising performance.

Missing Feature Hierarchy or Production Sequence

Drawings often lack machining process logic, such as which features must be created first or which are dependent on others. This forces CAM programmers to infer production sequence, risking design intent deviation.

Why It Increases Cost – Incorrect sequencing increases setup time, affects tolerances due to stress relief during machining, and elevates the risk of scrap if critical features are distorted due to improper removal order.

Frigate’s Solution – Frigate integrates advanced feature-based recognition (FBR) tools that analyze geometric dependencies and generate optimal feature hierarchies. This system automates CAM planning by categorizing features by priority, accessibility, and tolerance sensitivity—ensuring production fidelity and minimizing deviation from design intent.

Conclusion

In CNC manufacturing, drawing quality equals production efficiency. Even the most advanced machine cannot overcome design flaws baked into a poorly planned drawing. Manufacturers can dramatically reduce cost and improve delivery consistency by resolving common CNC drawing mistakes—from tolerance overloads to machinability misjudgments.

When technical issues are addressed early, production becomes more predictable, scalable, and cost-effective.

Frigate’s engineering-led approach ensures that every part drawing is reviewed for manufacturing logic, material compatibility, and dimensional clarity—protecting time, budget, and performance in one streamlined process. Get Instant Quote to eliminate drawing-related issues and get production-ready parts without surprises.