Transformers are key components in many machines and devices. They change the electrical voltage from one level to another. Choosing the right transformer is very important for many industries, especially original equipment manufacturers (OEMs). When machines run at steady power levels for long periods, the transformer must be reliable, efficient, and cost-effective. This is why EI Transformers for steady load applications are often preferred for steady-load applications.

This blog will explore why EI Transformers are so efficient for steady load environments. We will examine the technical reasons behind their popularity and explain why OEMs trust these transformers for critical applications. You will also learn about the manufacturing capabilities that make these transformers a top pick for steady, continuous power needs.

How EI Transformers Are Efficient for Steady Load Applications

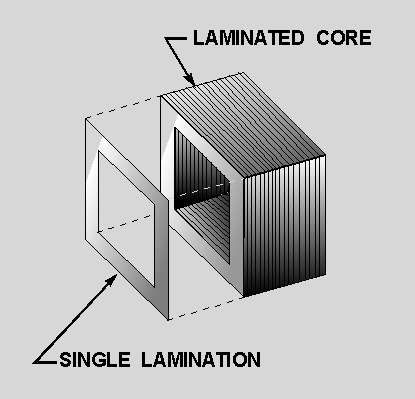

The core design of an EI Transformer for steady load applications is fundamental to its efficiency in steady load environments. The designation “EI” originates from the geometric configuration of its metal laminations, which are precisely stacked in the form of an “E” and an “I,” creating the magnetic core. This engineered structure enables efficient magnetic flux pathways, optimizing energy transfer during operation.

Magnetic Core Design and Energy Losses

Efficiency in EI Transformers for steady load applications largely derives from the effective management of magnetic energy within the core. During power transfer, inherent energy losses occur primarily due to hysteresis and eddy current phenomena.

- Hysteresis loss arises from the lagging response of the magnetic material’s domain alignment to alternating magnetic fields, causing energy dissipation as heat.

- Eddy current loss results from circulating currents induced within the conductive core laminations by changing magnetic fields, which generate resistive heating.

Utilizing thin laminations of high-grade silicon steel significantly reduces eddy current formation by limiting the electrical path available for these circulating currents. This lamination strategy effectively minimizes core losses, especially under steady load conditions with relatively constant magnetic flux. Additionally, silicon steel’s superior magnetic permeability and low coercivity mitigate hysteresis losses, improving overall transformer efficiency.

Thermal Management

Steady load applications typically subject transformers to continuous operation at or near rated capacity, resulting in sustained thermal stress. The EI Transformer’s lamination arrangement creates physical gaps between the “E” and “I” sections that facilitate convective airflow, enhancing passive heat dissipation. This intrinsic design feature prevents excessive temperature buildup that could degrade insulation systems and winding integrity.

Moreover, the modular construction of EI Transformers for steady load applications allows for integrating active cooling solutions such as forced air or oil cooling, particularly in higher power ratings. Enhanced thermal management ensures the transformer maintains optimal operating temperatures, extending component lifespan and maintaining reliable performance under continuous load.

Stable Voltage Regulation and Acoustic Performance

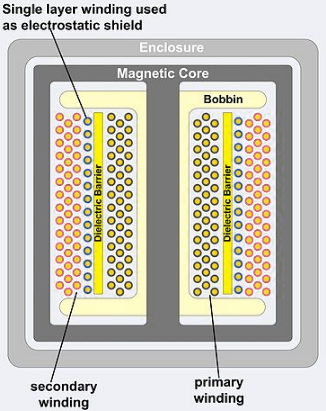

Maintaining a consistent output voltage is critical for equipment operating under steady loads. The EI Transformer exhibits stable voltage regulation owing to its core construction and precise winding configurations, which reduce voltage drops caused by internal impedance.

The stacked laminated core also mitigates magnetostriction-induced noise and vibration commonly observed in other transformer types. Reduced audible noise enhances operational environments, particularly in industrial and commercial applications with desirable low acoustic emissions.

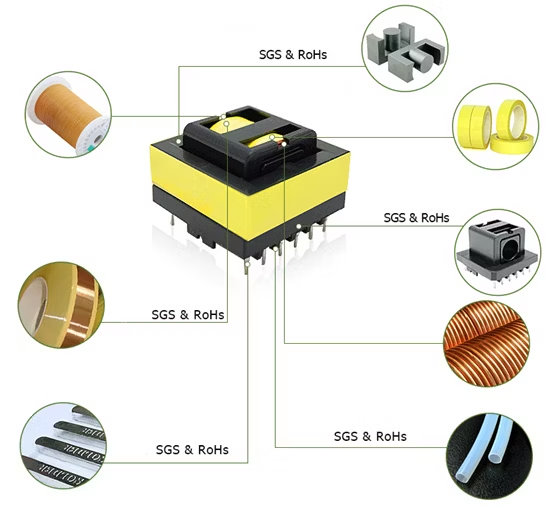

Material Selection and Electrical Integrity

Transformer reliability and longevity heavily depend on material quality. The selection of high-grade silicon steel laminations ensures minimal core losses and robust magnetic performance. Insulation materials are chosen based on thermal class ratings to withstand prolonged elevated temperatures without electrical degradation.

Copper or aluminum conductors are employed for winding assemblies, selected for their excellent electrical conductivity and corrosion resistance. The combination of premium materials and precise manufacturing techniques yields EI Transformers for steady load applications with superior electrical integrity, capable of sustained operation in demanding steady load scenarios.

Comparative Analysis with Other Transformer Designs

When evaluated against toroidal and shell-type transformers, EI Transformers for steady load applications frequently demonstrate superior efficiency and durability in steady load applications. While compact and lightweight, Toroidal transformers often experience higher inrush currents and exhibit reduced thermal tolerance during extended operation.

Shell-type transformers provide effective magnetic flux containment but tend to involve more complex construction and higher production costs. The EI Transformer design achieves a balanced trade-off between manufacturing simplicity, operational efficiency, and cost-effectiveness, making it a preferred solution where steady load performance is critical.

Why OEMs Prioritize EI Transformers for Steady Load Applications

OEMs in mission-critical industries—such as industrial automation, transportation, energy systems, and precision controls—prioritize transformer architectures that offer engineering predictability, thermal stability, electromagnetic compatibility, and long-term supply scalability. EI Transformers for steady load applications, particularly those designed and manufactured by Frigate, are a cornerstone technology for steady load environments due to their robust magnetic performance and structural resilience. Here’s why they remain a preferred platform –

Uptime Assurance via Magnetic and Thermal Stability

Frigate’s EI Transformers for steady load applications are engineered with advanced core stacking precision using laser-oriented CRGO laminations. This material exhibits a superior magnetic permeability-to-loss ratio, enabling stable flux density under continuous load without approaching saturation thresholds. Coupled with predictive thermal management modeling, Frigate designs each unit with optimal core window utilization and thermal pathways to prevent localized hot spots.

This ensures system uptime in 24/7 applications—minimizing thermal drift, dielectric fatigue, and premature winding failure. For CXOs managing fleets of industrial equipment, this translates into quantifiable uptime metrics, reduced field failure rates, and enhanced SLA adherence for mission-critical installations.

Lower Lifecycle Cost through Optimized Losses and Repairs

Frigate implements low-loss winding schemes that are digitally simulated via finite element analysis (FEA) to optimize both AC and DC resistance across a transformer’s load profile. Frigate’s design philosophy also incorporates serviceable core-clamp assemblies and sectionalized winding substructures that support in-situ repairs without decommissioning the full system.

Beyond CapEx, OEMs achieve long-term OpEx savings via lower no-load and load losses, validated through type-tested thermal run cycles. CXO-level benefits include increased ROI per asset, longer replacement intervals, and smoother cash flow projections driven by predictable maintenance and energy savings.

Precision Customization for OEM Load Profiles

Frigate collaborates directly with OEM design teams to embed application-specific requirements into the transformer’s magnetic topology. Each EI Transformer is tuned for precise voltage regulation, leakage inductance thresholds, and inrush current profiles using electromagnetic co-simulation platforms based on the downstream load architecture—inductive, capacitive, or hybrid.

Customized thermal dissipation modeling ensures passive cooling compliance across temperature classes (e.g., Class F or H), eliminating the need for ancillary cooling systems. This embedded engineering approach supports OEMs in achieving tighter system integration, improved thermal balance, and enhanced product efficiency ratings—critical for energy-labeled or regulated equipment.

Compliance Acceleration via Frigate-Certified Platforms

All Frigate EI Transformers for steady load applications are engineered to align with IEC 61558, UL 506, IEEE C57, and regional safety standards as a default baseline. Frigate maintains a library of pre-qualified insulation systems, magnetic materials, and creepage/clearance geometries audited and validated through recurring compliance cycles.

This allows OEMs to reduce their product certification timelines by integrating transformers that have been pre-engineered with test traceability, dielectric withstand margin data, and standard-conformant design features. For CXOs overseeing global product launches, this reduces time-to-market risk, legal exposure, and third-party certification delays.

Resilience to Harmonics, Noise, and Transients

Frigate transformers are uniquely suited for power environments rich in electrical noise, harmonics, and voltage transients. Through dual-shielded winding zones and distributed interleaving, Frigate suppresses interwinding capacitance and harmonically-induced heating—key for systems driven by VFDs, switch-mode supplies, or high-crest-factor loads.

Mechanical resonance is suppressed using rigid core frame assemblies with vibration isolation pads to eliminate acoustic noise and physical fatigue. This level of resilience directly reduces total system degradation and extends transformer life, which is especially crucial in process-intensive industries like oil & gas, semiconductor fabrication, and smart manufacturing.

Supply Chain Scale with Manufacturing Precision

Frigate’s transformer platforms are supported by digital twin-enabled manufacturing at multiple ISO 9001-certified facilities worldwide. Standardized build protocols, automated winding lines, and batch-level material tracking enable consistent quality regardless of volume scale.

For OEMs, this means zero ramp-up risk from pilot to production. Volume flexibility ensures on-time delivery during unpredictable demand spikes or new product introductions. CXOs benefit from stable procurement strategies, minimized supply chain disruptions, and long-term sourcing partnerships built on predictable quality and fulfillment precision.

Smart Transformers with Embedded Telemetry

Frigate offers embedded digital twin models and supports sensor integration for voltage, current, thermal stress, and core saturation tracking in real time. This creates a bridge between traditional transformer behavior and next-gen predictive maintenance systems.

Data from field-deployed transformers can be streamed to OEM SCADA or IoT platforms, enabling diagnostics, anomaly detection, and failure forecasting at the transformer level. This transforms what was once a passive electrical component into a smart node in the OEM’s larger reliability and analytics strategy.

Conclusion

Choosing the right transformer is critical. EI Transformers for steady load applications offer a unique combination of efficiency, reliability, and cost-effectiveness. Their laminated core design reduces energy losses and improves thermal management, making them ideal for continuous operation.

OEMs prioritize these transformers because they help reduce downtime, optimize total lifecycle costs, and ensure compliance with global standards. The ability to customize and scale production adds to their appeal. Strong manufacturing capabilities, such as those offered by Frigate, provide OEMs with the quality and consistency needed to succeed.

Partner with Frigate today to integrate high-performance EI transformers for steady load applications, long-term efficiency, and seamless OEM alignment.