Before starting the manufacturing process, designers and engineers must validate and optimize the quality and perfection of the parts. Moreover, they must test the specific materials and their performance characteristics as a proof of concept. This is where prototype CNC machining services come into the spotlight.

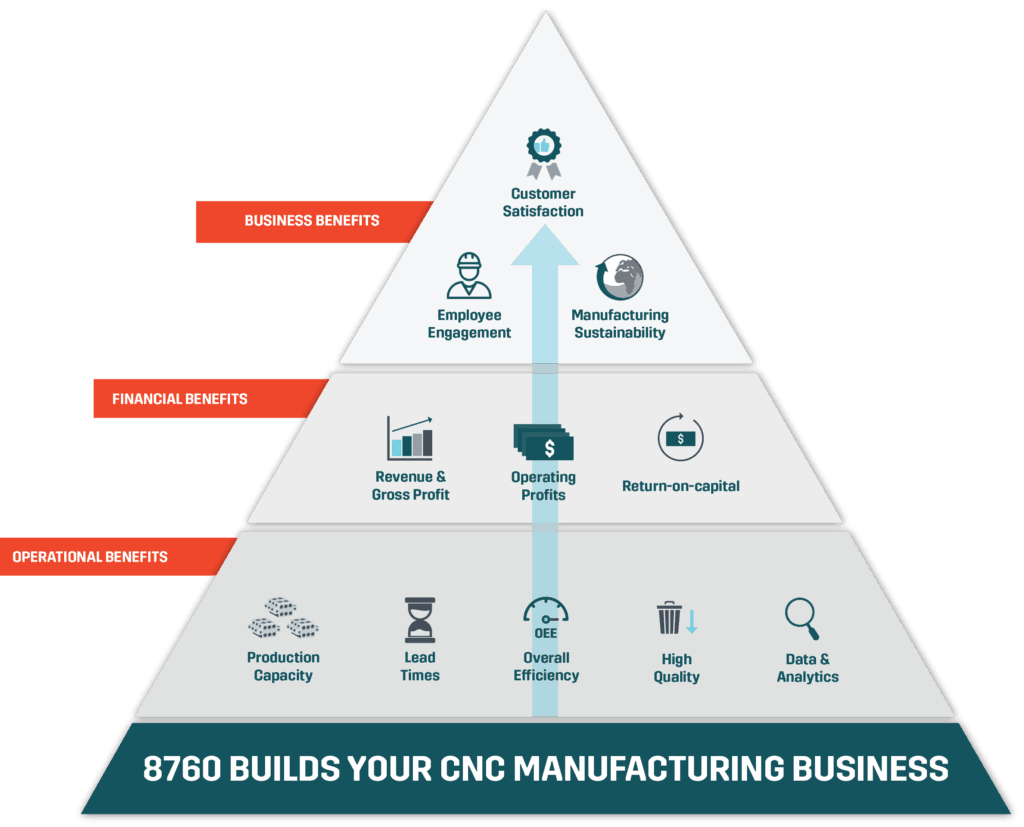

CNC Prototyping offers a host of benefits regardless of the application. It can significantly shorten the design cycle, optimize parts for end-use functionality, help product development teams anticipate challenges before they cause costly redesigns, and find cost-cutting opportunities. Ultimately, it makes production more efficient and cost-effective.

This article will discuss how Prototyping CNC machining can help you turn your ideas into reality with precision and cost-effectively.

Why is Prototype CNC Machining Services good for your business?

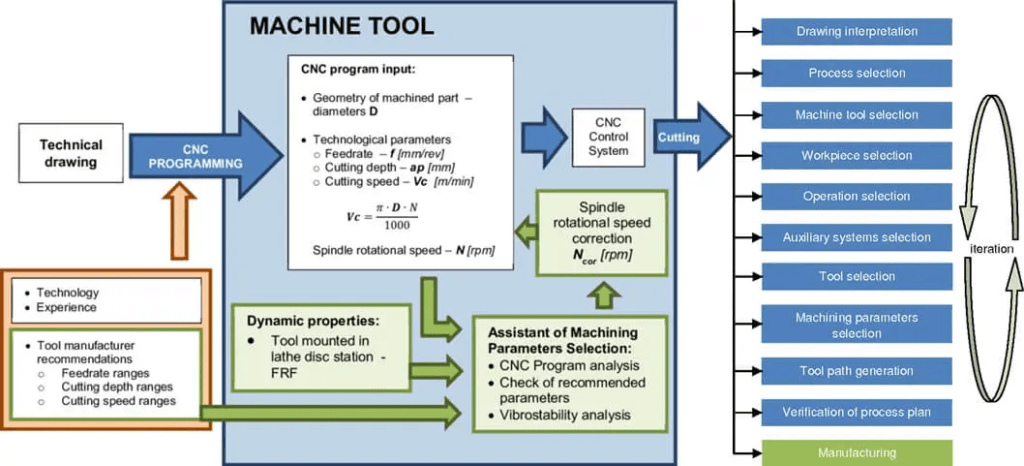

There are several reasons why CNC machining is your perfect method for prototyping. First, it is very accurate and precise. This is because CNC machines use computers to control the movement of the workpiece and the cutting tool. These computers follow your design exactly, ensuring the prototype is an exact copy.

Another reason prototype CNC machining services are great for prototyping is their speed. Unlike methods like injection molding, where you might have to wait months for the molds to be ready, CNC machining is much faster.

With the CNC process, you create a 3D model of your product on a computer. This model is then turned into CAM files, like instructions for the CNC machine. These files contain the G Code, which tells the machine how to move and cut during prototyping. This way, you get your prototype quickly and accurately.

Advantages of using CNC Machining for prototypes

When choosing prototype CNC machining services for your prototypes, consider some of the advantages of this process. Here are some of the benefits of making CNC machining your first choice for prototyping:

High Accuracy and Precision

CNC machining helps make prototypes with very high precision and accuracy. This is because the cutting tools are controlled by computers, which makes everything very precise.

Since the machining process is so accurate, any mistakes or problems with the prototype usually come from the design itself, not the machining.

Cost Effective

CNC for rapid prototyping is done in small batches so the manufacturer can visually and functionally check the product. Making small batches is a safe way to protect the manufacturer or product developer from losing money. If a defect is found during the assessment, the loss would be small compared to finding a defect after making many products.

Consistency and Repeatability

Prototype CNC machining services are great because they can make the same thing repeatedly without mistakes. You’ll get an exact copy using the same design and process every time.

Unlike other methods like injection molding, where the mold wears out after a while and changes the design a bit, CNC prototyping machines stay accurate. They can keep making perfect copies of your design no matter how often they do it.

Material Versatility

While there is a limit to the number of materials manufacturing and machining processes like 3D printing and injection molding can work with, CNC prototyping offers more versatility. With CNC prototyping, various materials, ranging from plastics and wood to the strongest metal prototype, can be machined.

Material options for prototype CNC machining services include plastics such as HDPE, PS, LDPE, PC, POM, PP, PMMA, PCGF, ABS, PAGF, and Teflon. Metals and metal alloys ideal for CNC prototype machining include aluminum, steel, stainless steel, magnesium, titanium, zinc, copper, bronze, and brass.

Time Saving Process

Creating prototypes with CNC machines is quick because molds or other special tools are not needed first. If you need to change the design, it’s easy: update the CAD and CAM files and then make the prototype again with the CNC machine. This makes it fast to adjust and perfect your design.

Applications of Prototype CNC Machining Services

CNC prototype machining is a popular way to make prototypes that are used in many industries. Some industries rely on this process more than others. Here are a few examples of these industries:

Automotive Industry

The automotive industry needs parts and models that are very precise and fit perfectly. This includes important components like brakes, gears, suspension parts, and wheels. These parts must meet very tight tolerances to ensure the safety of vehicles.

Manufacturers create prototypes using CNC machining before making many of these parts real. They test these prototypes in vehicles to make sure they fit and work correctly. CNC prototype machining services would make it easier to consistently make automotive parts that meet exact specifications.

Aerospace Industry

CNC prototyping technology is used mainly in the aerospace industry for two essential purposes. First, it helps create parts with very high precision and accuracy. This means the parts are made as planned, ensuring they fit and function perfectly. Second, CNC prototyping tests these parts to ensure they work well and don’t fail when an aircraft is flying. Standard aircraft parts made using CNC prototyping include:

- Manifolds (which help control the flow of fluids).

- Bushings (which support rotating parts).

- Airfoils (which are crucial for aerodynamics).

Defense

The Research and Development (R&D) department often uses CNC prototype machining in defense. This technology is crucial for quickly making parts for vehicles, aircraft, and other military equipment. CNC machining is preferred because it can produce parts quickly, no matter how tough the material is. This allows the military to develop and test new equipment efficiently.

Frigate Offers Prototype CNC Machining Services For Rapid Prototyping

Frigate combines advanced technology with over a decade of CNC prototyping experience to turn your CAD models into high-quality prototypes. We offer a full range of CNC machining services, from precision prototyping to complete production runs.

No matter your industry, our extensive experience ensures we can create prototypes that meet your exact specifications. Just upload your CAD files, and we’ll provide you with Design for Manufacturing (DfM) feedback and a quote.