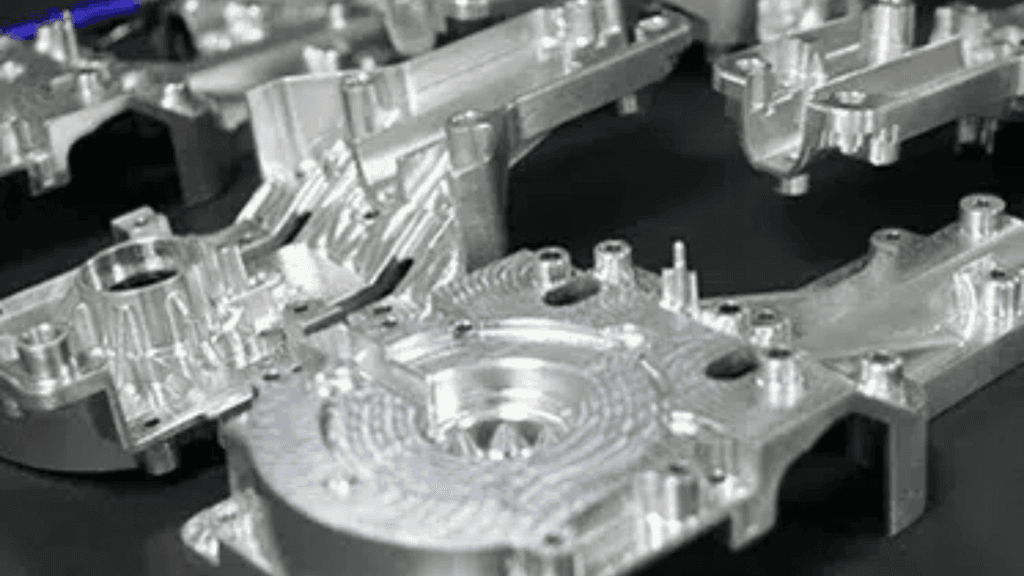

Rapid Prototyping Casting Services

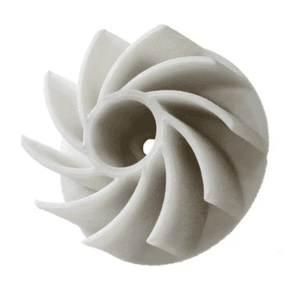

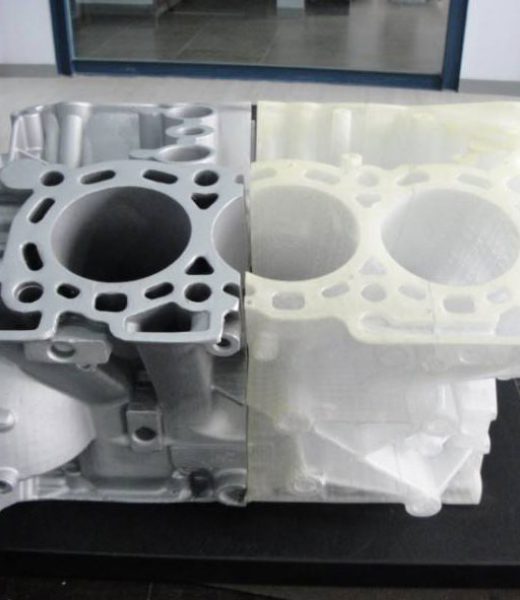

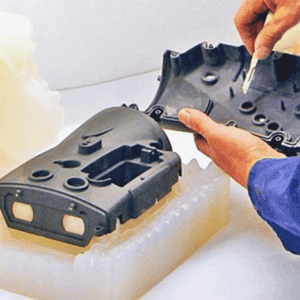

Frigate offers quick-turnaround rapid prototyping castings to help you test part designs without needing expensive, complex tooling. We can also directly print 3D plastic patterns from your 3D CAD files using advanced rapid prototyping technology. This lets you validate your designs faster and more efficiently, ensuring the final product meets your specifications.

Our Clients

Advantages of Rapid Prototyping Casting Services

On-Demand Manufacturing

Get low-volume manufacturing when you need it. We offer help with product design, development, prototyping, and production, making the process smooth and efficient from start to finish.

Heat Tempering

Our skilled engineers can guide you in choosing the right heat-treating process for your casting. This ensures that your project meets the highest standards for strength and durability. Let us help you get the best results.

Product Development

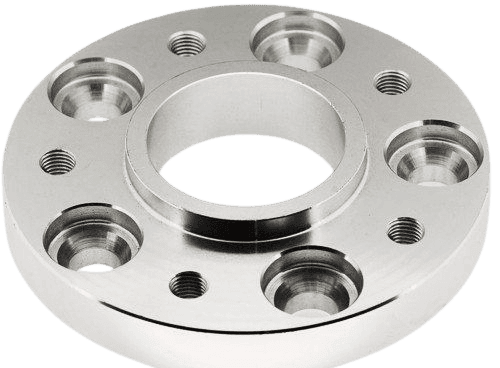

Our team of experts in metal casting and CNC machining will assist you in designing cost-effective, easy-to-produce products and parts in low volumes. We optimize the design for efficiency while maintaining high quality throughout the process.

Early Detection of Design Flaws

Rapid prototyping helps identify and fix design flaws early, minimizing risks during final production. This early detection allows necessary changes to be made before moving to full-scale production, reducing the likelihood of costly errors later.

Quick turn Investment Castings Capabilities of Frigate

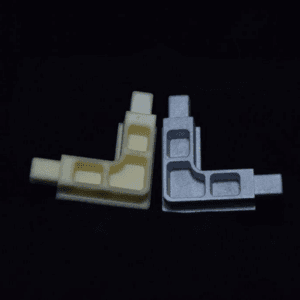

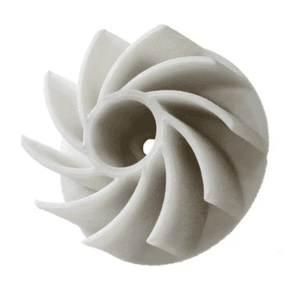

Our prototyping experts and CP wax printers can quickly turn your CAD designs into 3D-printed prototype patterns. Once the castings are complete, we handle secondary processes like heat treatment, non-destructive testing, and machining. We ensure the parts meet tight dimensional tolerances and can create complex shapes with undercuts. Our team is experienced with rapid prototype patterns, including QuickCast and 3D CP wax patterns, using advanced in-house ProJet printers to deliver high-quality results.

Get Your Quote Now

- Instant Quotation

- On-Time Delivery

- Affordable Cost

Our Rapid Prototyping Casting Process

Start with a digital product design, often created using computer-aided design (CAD) software.

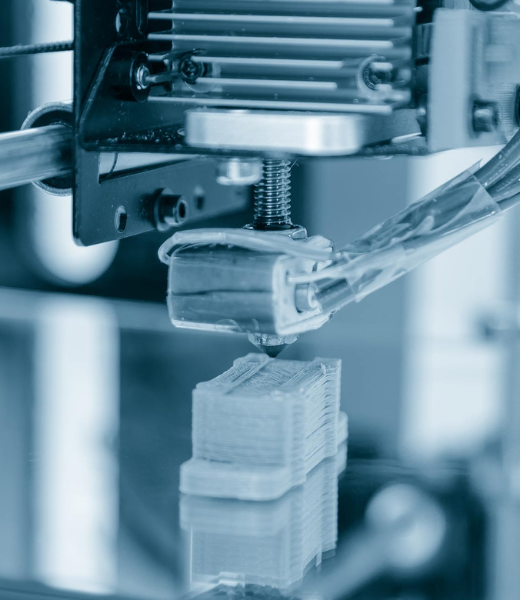

Use methods like 3D printing or CNC machining to build the prototype based on the digital design. These techniques can quickly turn a design into a physical object.

The prototype is tested to check its functionality, durability, and performance. This helps identify any issues before mass production.

Based on the testing results, adjustments are made to the design to improve the product.

Post-Processing in Rapid Prototype Casting

Rapid prototype casting requires precise post-processing to enhance surface quality, durability, and performance. Various finishing techniques like heat treatment, anodizing, CNC machining, and polishing refine cast components for aerospace, automotive, and medical applications.

Aerospace (turbine blades), Automotive (engine parts)

Hardness: 40 - 65 HRC

Automotive (gear housings), Aerospace (structural components)

Hardness: 200 - 500 HV

Electronics (heat sinks), Aerospace (aircraft parts)

Conductivity: 0.1 - 0.6 Ω·mm²/m

Automotive (connectors), Medical (surgical instruments)

Adhesion: 5B (ASTM D3359)

Industrial (machine components), Consumer Goods (appliance parts)

Pressure: 3 - 7 bar

Aerospace (landing gear), Automotive (chassis components)

Depth: 10-50 µm

Medical (implants), Consumer Goods (wearable devices)

Surface Ra: 0.4 µm

Automotive (engine brackets), Aerospace (sensor housings)

Removal: 0.01 - 0.1 mm

Jewelry, Medical (prosthetics)

Gloss: 60 - 90 GU (gloss units)

Consumer Electronics (casings), Industrial (pump housings)

Methoding in Rapid Prototype Casting

Aerospace (thin-wall structures), Automotive (engine blocks)

Industrial (gear housings), Energy (turbine blades)

Electronics (heat sinks), Medical (surgical tools)

Automotive (aluminum components), Defense (armor casings)

Heavy Machinery (pump housings), Aerospace (structural parts)

Automotive (cylinder heads), Energy (wind turbine hubs)

Industrial (valves, manifolds), Aerospace (aircraft brackets)

Electronics (micro-components), Automotive (chassis parts)

Medical (implants), Consumer Goods (ergonomic casings)

Aerospace (turbine vanes), Defense (missile components)

Rapid Prototyping Casting Materials

We deliver high-quality rapid prototyping casting services using various advanced materials. Our expertise ensures that your designs are brought to life with precision and speed, no matter how complex the requirements.

Lightweight and strong, aluminum is often used for automotive, aerospace, and electronics parts. It offers excellent heat resistance and is easy to machine.

It is known for its corrosion resistance and durability. This material is ideal for parts that withstand harsh environments or high-stress applications.

Zinc is a versatile material with good strength. It's commonly used for small, complex parts and is also known for its ability to create detailed and precise prototypes.

Brass is valued for its corrosion resistance and is often used in plumbing, electrical, and decorative applications. It is also good at machinability and durability.

Magnesium is one of the lightest metals available and is often used in aerospace and automotive industries where weight reduction is crucial. It's also strong and offers good heat dissipation.

Plastic resins can be used for lower-strength prototypes. These materials are easier to mold and are cost-effective for early design testing.

A Fusion of Tradition and Innovation

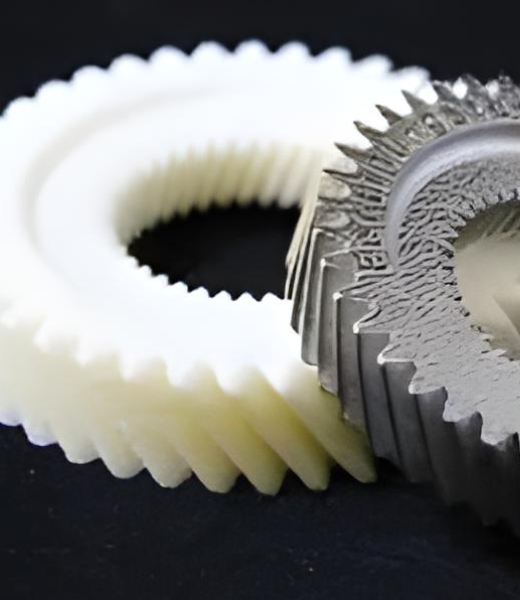

Frigate Die Casting Services blends 3D printing with precision machining to create high-quality prototypes. This approach ensures that each prototype is not just a basic model but a nearly exact version of the final product. Frigate can meet strict quality standards using both technologies, allowing prototypes to be fully tested for real-world applications. Combining 3D printing’s design flexibility and machining accuracy results in reliable, detailed prototypes ready for rigorous evaluations. This process helps ensure the final product performs as expected in real-life conditions.

Compliance for Rapid Prototyping Casting Services

Frigate’s Lost-Foam Casting services fully comply with industry-specific regulations and standards, ensuring superior quality and reliability. We integrate advanced quality control systems and adhere to stringent environmental and safety protocols. Our services are designed to meet the precise needs of each project while maintaining the highest standards in material integrity and production efficiency. Every aspect of our casting process is thoroughly documented, ensuring all products comply with relevant certifications and regulations.

Key Compliance Certifications

Ensures rigorous quality management across all stages of production.

Specifies material requirements for high-performance die castings.

Ensures chemical safety in materials used for prototyping.

Guarantees the exclusion of hazardous substances in manufacturing processes.

Automotive industry standard for quality management in rapid prototyping.

Confirms thread standards and fit for mechanical components.

Certification for environmental management, ensuring sustainability in prototyping practices.

Tonnage / Capacity in Rapid Prototype Casting

Rapid prototype casting requires precise tonnage selection based on material flow, mold filling, thermal contraction, and structural integrity. Optimal capacity ensures dimensional accuracy, minimal porosity, and uniform solidification for high-performance applications.

Automotive (engine blocks), Aerospace (structural parts)

Industrial (pumps, housings), Medical (implants)

Aerospace (thin-wall structures), Electronics (heat sinks)

Automotive (gear housings), Defense (armor casings)

Heavy Machinery (engine components), Consumer Goods

Aerospace (lightweight parts), Electronics (enclosures)

Automotive (precision gears), Medical (surgical tools)

Industrial (valves, manifolds), Energy (turbine blades)

Automotive (cylinder heads), Aerospace (structural panels)

Electronics (connectors), Medical (prosthetics)

Dimensions in Rapid Prototype Casting

Dimensional accuracy in rapid prototype casting is crucial for tolerance control, geometric stability, and mechanical fit, ensuring precise assembly, minimal deformation, and optimal structural performance across applications.

Aerospace (structural components), Automotive (engine blocks)

Electronics (heat sinks), Automotive (lightweight casings)

Medical (implants), Industrial (precision gears)

Aerospace (aero-structures), Automotive (chassis parts)

Heavy Machinery (engine housings), Energy (turbine blades)

Consumer Goods (plastic enclosures), Automotive (body panels)

Industrial (valves, manifolds), Aerospace (aircraft fittings)

Electronics (thin-walled casings), Aerospace (cooling fins)

Medical (micro-components), Automotive (sensor housings)

Industrial (gear housings), Consumer Goods (appliance parts)

Tolerance for Rapid Prototyping Casting Services

Ensures that the overall dimensions of the prototype match design specifications.

Tolerance on the thickness of walls to ensure structural integrity and fit.

The smoothness of the surface, important for aesthetic quality and performance.

Ensures that features like holes, slots, and threads are accurately formed.

Tolerance on the diameter of holes to maintain functionality and fit.

Ensures surfaces remain flat for assembly and fitment of components.

Tolerance for the angles between surfaces, critical for proper alignment.

Ensures circular features, like holes or shafts, are within tolerance.

Quality Testing Standards for Rapid Prototyping Casting Services

Determines the material's ability to withstand pulling forces without breaking.

Measures the hardness of the material to ensure it meets performance requirements.

Detects any internal voids or air pockets that could compromise the part’s strength.

Verifies if the prototype fits within assembly components and operates correctly.

Measures how well the material performs under different thermal conditions.

Checks for visible defects such as cracks, leaks, or misalignments on the surface.

Inspection Techniques in Rapid Prototype Casting

Value/Range - 0.1 mm - 2 mm defect size

Aerospace (turbine blades), Automotive (cylinder heads)

Resolution: 5 µm - 100 µm

Medical (implants), Electronics (sensor housings)

Value/Range - 0.5 mm - 50 mm penetration depth

Energy (nuclear components), Industrial (gear housings)

Crack size: 0.01 mm - 2 mm

Defense (armor plates), Aerospace (airframe parts)

Detection depth: Up to 6 mm

Automotive (engine blocks), Industrial (shafts, gears)

Value/Range - ± 0.005 mm - ± 0.1 mm

Aerospace (aircraft brackets), Medical (prosthetics)

Accuracy: ± 0.01 mm - ± 0.05 mm

Consumer Goods (appliance casings), Automotive (body panels)

Value/Range - 20 - 700 HV (Vickers Hardness)

Heavy Machinery (pump casings), Automotive (brake components)

Elemental accuracy: ± 0.01% - ± 0.1%

Energy (turbine alloys), Industrial (high-strength castings)

Magnification: 50x - 1000x

Medical (bio-grade alloys), Aerospace (high-strength materials)

Industry Applications of Rapid Prototype Casting

Turbine blades, jet engine housings, satellite components

Cylinder heads, EV motor housings, suspension arms

Titanium implants, dental prosthetics, orthopedic tools

Micro heat sinks, semiconductor casings, sensor enclosures

UAV frames, missile guidance systems, armor plating

Wind turbine hubs, nuclear reactor components, fuel cells

Gear housings, hydraulic valve bodies, pump casings

Smart wearables, high-performance sports gear, power tools

Advanced Rapid Prototyping Solutions for Aerospace Engineering

Frigate’s rapid prototyping services are essential for the aerospace industry. We use cutting-edge technologies like 3D printing and precision machining to create prototypes quickly and accurately. This allows aerospace engineers to test and refine designs swiftly, ensuring that each component meets rigorous safety and performance standards.

Our prototypes provide a near-exact replica of the final product, enabling thorough testing and validation before full-scale production. With our rapid prototyping, aerospace companies can reduce development time, lower costs, and achieve high-quality results that meet their industry’s demanding requirements.

Industries We Serve

- Solid Progress

What You Gain with Us

We make your profitability and operations easier with practical approach.

↓ 7-8%

OPS COST

↓ 2-3%

COGM

3X

Aggregation

↑ 25%

Machinery Utilisation

↓ 50%

Expedition

↑ 30%

Frigater Revenue

Reduce Costs and Lead Time Using Rapid Prototype

At Frigate, we deliver aerospace-grade rapid prototype castings directly from your CAD files (.STEP, X_T, STL, and other formats). Our streamlined process allows us to produce high-quality prototypes in as little as five weeks. We cater to various designs—from single-piece oil and gas prototypes to full production runs for aerospace components.

Our rapid prototype castings are crafted from the same superior materials used in our investment castings, ensuring consistent quality and performance. Leveraging advanced 3D printing technology, we offer a variety of material options to suit your project’s specific needs, effectively balancing cost and quality. At Frigate, we aim to support your innovation with precision-engineered prototypes that meet the highest industry standards.

Check Out Our Blogs

What Our Customers Say about Frigate

21%

Faster Manufacturing

Having Doubts? Our FAQ

Check all our Frequently Asked Question

Rapid prototyping can use various materials, including resin, metal, and plastic. Each material has its properties. For example, metal prototypes are strong and durable, while resin prototypes are great for detailed designs. Choosing the right material depends on the final product's requirements.

In rapid prototyping, 3D printing creates a mold for casting. The quality of the 3D-printed mold directly impacts the final casting. The casted part will have better accuracy and finish if the mold has fine details and smooth surfaces. This ensures a high-quality final product that meets specifications.

Yes, rapid prototyping significantly cuts down lead times. By quickly creating prototypes, manufacturers can test designs and make adjustments before the final casting. This speeds up the overall production process, allowing for faster delivery of the final product.

Advanced techniques like laser scanning and computer numerical control (CNC) machining are used to ensure dimensional accuracy. These methods precisely measure and adjust the prototypes, ensuring they match the design specifications. This accuracy is crucial for successful casting.

Rapid prototyping allows for creating complex geometries that traditional methods may struggle with. It enables the design of intricate shapes and features that enhance product functionality. This flexibility helps innovate new designs without traditional casting processes' constraints.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Global Sales Office

818, Preakness lane, Coppell, Texas, USA – 75019

Registered Office

23, 6th West Street, Balaji Nagar, Kattur, Pappakuruchi, Tiruchirappalli-620019, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ