CNC Aluminium Warping is a major concern in manufacturing workflows that demand tight dimensional control and surface integrity. In aluminum machining, even minor deviations can compromise assembly precision, increase rejection rates, and affect the functional reliability of end products.

According to industrial surveys, up to 25% of production delays in high-precision aluminum parts stem from warping-related failures. The implications go beyond scrap, including operational downtime, rework cycles, and customer dissatisfaction.

This guide provides a structured, process-driven approach to minimizing CNC Aluminium Warping. It focuses on critical process variables and how aligning machining practices with engineering principles can produce consistent, stable parts. Each method is explained in relation to how Frigate addresses the core technical challenges.

Methods to Avoid Warping in Aluminium CNC Machining

Warping is a critical issue in aluminum CNC machining that affects dimensional accuracy, part stability, and downstream performance. It often results from material stress, thermal imbalance, and suboptimal machining strategy.

Preventing CNC Aluminium Warping requires a controlled, data-driven approach—from raw material selection to in-process monitoring. The following methods outline how Frigate applies technical precision across each stage to minimize distortion and ensure consistent part quality.

Aligning Material Science with Machining Strategy

CNC Aluminium Warping often starts long before the first tool touches the part. One of the most overlooked causes of distortion is the mismatch between aluminum material selection and the machining strategy. Different aluminum alloys respond differently under stress. For example, 6061-T6, 7075-T6, and 2024 each carry varying residual stress levels based on how they were heat-treated and formed—whether extruded, rolled, or forged. If that residual stress is not identified and accounted for, removing material during machining can lead to internal tension releasing unevenly, bending the part.

Frigate solves this by tightly aligning material science with the machining plan. All raw materials go through a mechanical property review and certification check. Their mechanical history is verified to ensure material-grade-to-geometry compatibility. In addition, pre-machining stress relief is applied when necessary to relax internal stresses before cutting begins. Frigate ensures a stable starting point to avoid CNC Aluminium Warping by understanding how aluminum behaves at a microstructural level.

Simulation-Based Machining to Predict Stress Accumulation

Complex aluminum parts are at higher risk for distortion, especially those with thin walls, deep pockets, or curved profiles. Traditional toolpath planning can introduce uneven mechanical forces and heat, accumulating unexpected stress. This often results in CNC Aluminium Warping that only becomes visible after final machining. To prevent this, Frigate uses simulation-based machining strategies. Before cutting begins, the part geometry is digitally simulated using CAM software paired with Finite Element Analysis (FEA). These simulations show where heat, force, and material removal will affect structural balance.

Based on these insights, Frigate engineers adjust toolpath strategies, entry/exit angles, and cut depths to maximize stress distribution. The result is a machining process optimized not just for speed but for dimensional accuracy and surface flatness. This predictive approach eliminates guesswork, reduces trial-and-error, and greatly minimizes CNC Aluminium Warping, especially in high-precision applications.

Precision Workholding Systems to Prevent Clamping-Induced Distortion

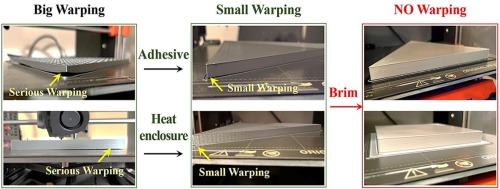

Even with perfect material and toolpaths, improper clamping can cause aluminum parts to warp. The clamping pressure can lock in internal stress when the part is tightly held in a fixture during machining. This stress escapes once the clamps are released, leading to bending or twisting. This is a common source of CNC Aluminium Warping in thin or asymmetric parts.

Frigate addresses this problem through engineered workholding systems tailored to each part. Depending on the part geometry and material type, Frigate designs hybrid fixtures combining vacuum and mechanical clamps. These fixtures apply the right amount of hold-down force evenly distributed across the surface. Thermal neutrality is also considered—fixtures are made from materials that won’t expand faster than the part itself. Before production, each fixture undergoes load analysis to ensure no unintended deformation is introduced. With this precision in fixturing, Frigate keeps the part balanced throughout the process, directly reducing warping risk.

Thermal Load Management During Machining

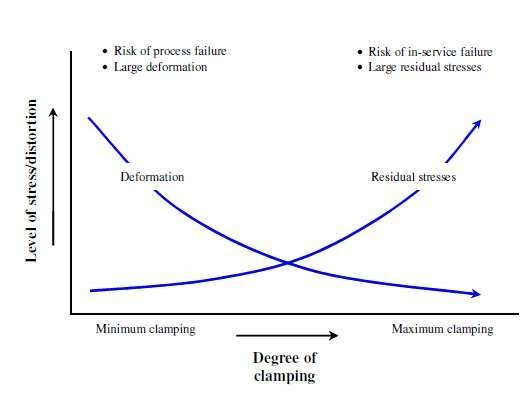

One of the biggest challenges in machining aluminum is heat. Aluminum machines quickly, but it also heats up fast. If heat is not managed properly, the part expands unevenly. When it cools, it shrinks—but not always back to the same shape. This uneven expansion and contraction are major causes of CNC Aluminium Warping. Frigate combats this with advanced thermal load control.

First, high-flow coolant systems carry heat away from the tool and part surface. The coolant is precisely delivered at critical engagement points to ensure balanced temperature zones. Second, toolpath strategies are optimized to avoid generating too much heat in one area before moving to the next. Based on sensor feedback, adaptive spindle speeds and feed rates are adjusted in real-time. Frigate even uses heat mapping tools to ensure the temperature remains uniform. All these actions help control the thermal behavior of the part, keeping it dimensionally stable throughout machining.

Post-Machining Stabilization and Stress Relief

Even after careful machining, aluminum parts can still hold hidden stress. This stress often causes delayed warping—meaning the part looks fine when it comes off the machine but bends days later during coating, storage, or assembly. This problem is especially common in large parts or parts with high aspect ratios. To eliminate this delayed CNC Aluminium Warping, Frigate includes post-machining stabilization as part of the workflow. Low-temperature heat treatment, thermal cycling, or cryogenic treatment may be used depending on the material and part geometry.

These methods help the part “settle” by slowly releasing internal tension without altering mechanical properties. For example, a controlled thermal cycle at 150°C for several hours can stabilize 7075-T6 aluminum without softening it. After treatment, each part is inspected again for flatness and profile accuracy using high-resolution, non-contact metrology tools. This ensures that the final part remains stable—even weeks after machining.

In-Process Metrology and Feedback Control

Waiting until the final Machining inspection to catch warping issues is risky and expensive. If a part has already warped, it often means the entire machining time is wasted. That’s why real-time feedback is essential to preventing CNC Aluminium Warping. Frigate incorporates in-process metrology during every critical phase of the machining cycle. Probing systems mounted on the CNC machine check for dimensional accuracy between toolpaths. 3D laser sensors continuously scan for warpage as the part is cut.

These tools feed data into a Statistical Process Control (SPC) system, which flags any dimensional drift immediately. When a deviation is detected, toolpaths or speeds are adjusted automatically. This feedback loop keeps the part on track and avoids the build-up of error. Instead of discovering warping after the fact, Frigate corrects issues in real-time, greatly reducing scrap rates and improving yield consistency.

Process Repeatability for Medium to High-Volume Production

Even small process variations can accumulate into bigger problems over time in batch production. Things like tool wear, ambient temperature changes, or operator handling can cause gradual shifts in accuracy. When machining aluminum at scale, these small changes can lead to increasing cases of CNC Aluminium Warping as production continues. Frigate prevents this with process standardization and repeatability. Every job has a tooling library calibrated for the specific aluminum alloy used.

Machine calibration is performed every 48 to 72 hours using laser alignment tools. The production environment is climate-controlled, with ambient temperature within a 1.5°C range to prevent thermal drift. Operators follow digital job workflows, including checklists, validation steps, and recorded inspections. Each production batch is reviewed using statistical data to catch early signs of variation. If a trend is detected, it’s corrected immediately across all machines. This disciplined control makes it possible to scale aluminum part production while keeping warping issues near zero.

Conclusion

CNC Aluminium Warping is not a simple problem. It doesn’t come from one cause—it’s the result of many small factors working together. Raw material stress, clamping forces, heat, tool pressure, and post-process movement affect the final shape. But warping isn’t inevitable. With the right strategy, every process stage can be optimized to prevent it.

Frigate offers a complete solution—from material inspection and predictive simulation to fixturing, thermal control, in-process feedback, and post-machining stabilization. Get Instant Quote for precision you can trust. Contact the engineering team today for a customized consultation.