CNC Turning Services for Food Processing Machinery

Frigate delivers precision-turned components for food processing equipment using high-performance CNC turning centers. Our turning capabilities meet stringent hygiene, dimensional, and repeatability standards across batch and volume production.

Our Clients

- Process Efficiency

Advantages of Our CNC Turning Service

Our turning operations meet industry-grade precision using close-tolerance live tooling, high-pressure coolant delivery, and dual-spindle configurations.

Thread Integrity in Sanitary Joints

We machine burr-free threads that maintain seal quality and reduce microbial contamination in CIP-compliant piping assemblies.

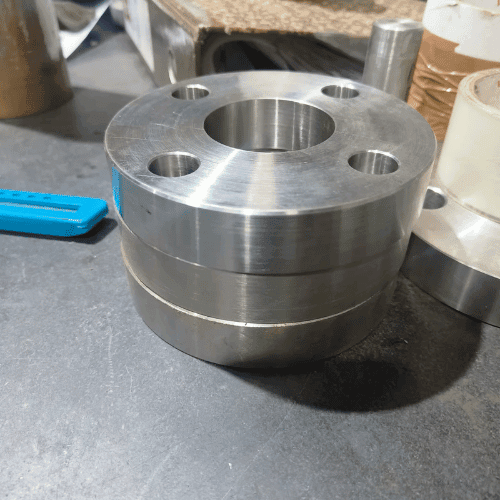

Bore Alignment for Shaft-Fit Parts

Precision turning helps align concentric bores and shoulders critical for augers, drums, and motor housings in food-grade assemblies.

Toolpath Strategies for Thin-Walled Forms

Our programs reduce vibration and tool wear while maintaining shape control for components like filter housings and pump shells.

- Process

Our CNC Turning Process

We apply controlled feed rates, high-speed chucking, and real-time tool offset adjustments to maintain consistent surface finish and dimensional control.

Our team designs the part in CAD software with focus on radial symmetry and tool clearance.

CAM software generates toolpaths based on spindle speeds, feed rates, and material hardness.

Operators load the raw bar stock and calibrate live tooling attachments, ensuring optimal alignment.

The part spins while stationary or live tools shape it via precision radial and axial cuts. Also, Our machines track spindle load and thermal drift in real time.

We perform part-off, facing, and secondary polishing before moving to the inspection stage.

Every part undergoes inspection using CMMs and profile projectors to verify dimensional and geometrical tolerances.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

- Surface Finish

Precision Surfaces for Turned Components

Our turning process supports Ra values under 0.8 μm, helping reduce friction and residue buildup in moving parts and fluid channels.

Anodizing

Give your aluminum parts a tough, corrosion-resistant shield with anodizing, reaching surface hardness up to HV 500, while enhancing electrical insulation and durability.

Mechanical Finishing

Smooth out imperfections and refine surfaces to Ra 0.2 µm or better with mechanical finishing techniques like grinding, polishing, and bead blasting.

Heat Treatment

Boost material strength and hardness by heat treating parts at temperatures up to 1100°C, ensuring they meet the mechanical demands of your application.

Electroplating

Add protective or functional metal coatings with electroplating, delivering consistent layers as precise as ±2 µm for improved corrosion resistance and conductivity.

Our Machined Products

We support your production needs with CNC-machined parts, subassemblies, and performance-critical components.

- Material Capabilities

Turned Part Materials for Food Equipment

We turn various stainless steel grades and FDA-approved polymers based on the hygiene and wear requirements of each application. Every material is selected for its machinability and long-term contact safety.

- Improve corrosion resistance with food-grade 316 and 304 stainless steels

- Enable FDA-compliant polymer components

- Maintain dimensional integrity in long runs using stabilized bar stock

A2 Tool Steel is a high-carbon, high-chromium steel known for its toughness and wear resistance. It’s ideal for producing durable, high-strength parts that can withstand heavy use.

Aluminum is a lightweight, corrosion-resistant metal with good machinability. Because of its strength-to-weight ratio, it’s commonly used in aerospace, automotive, and various industrial applications.

Brass is a copper-zinc alloy known for its machinability and corrosion resistance. It’s used for components requiring precise detailing and good mechanical properties.

Bronze is a copper-tin alloy with excellent wear resistance and strength. It’s often used for bushings, bearings, and other friction-prone components.

Cast Iron is known for its high wear resistance and machinability. It’s used in heavy-duty applications such as machinery parts and engine components.

Copper offers excellent thermal and electrical conductivity. It’s used in applications requiring heat dissipation or electrical conductivity, such as electronic components.

Steel is a versatile material known for its strength and durability. It’s used in various applications, from construction to automotive parts.

Titanium is a lightweight, high-strength metal with excellent corrosion resistance. It’s used in aerospace, medical implants, and high-performance engineering applications.

Stainless Steel offers high corrosion resistance and strength. It’s widely used in applications ranging from kitchen equipment to industrial machinery.

Zinc is a ductile and corrosion-resistant metal known for its excellent machinability, especially in its alloy forms. It's often used for components requiring intricate details, good surface finish, and precise dimensions, commonly found in automotive, hardware, and electrical applications.

- Process Control Integration

Key Highlights

Our structured production process keeps quality checkpoints, helping avoid rework and delays in high-volume food machinery builds. This consistency supports scalable batch production with traceability and tolerance adherence.

- Minimize production disruptions with consistent first-pass yield across turned part batches

- Maintain packaging timelines by syncing delivery schedules with your build slots

- Avoid tooling delays with upfront part complexity analysis and clear fixturing plans

- Improve vendor traceability through serialized batch tracking and digital delivery logs

- Reduce NCRs with verified tolerance reports linked to in-process checkpoints

- Regulatory Compliance

Compliance for CNC Turning in Food Processing Equipment

Frigate’s CNC Turning operations meet global safety, hygiene, and traceability mandates for food processing environments. Our process flows follow current industry practices, audits, and documentation requirements across regulated markets.

- Support hygiene audits with material certificates and contact-safe surface specs

- Simplify export documentation with format-ready inspection and compliance records

- Align with industry audits through validated setup sheets and job-specific process logs

Demonstrates adherence to quality management standards for turned component production.

Supports food-safe handling protocols in production environments.

Allows use of FDA-grade materials in contact surfaces.

Aligns with sanitary design for food equipment components.

Supports compliance with chemical safety and reporting norms.

Enables compliance for turned parts in EU food processing lines.

We provide documentation support to help customers secure UL certification for assemblies using our turned components.

- We export to 12+ countries

Frigate’s Global Presence

Frigate takes pride in facilitating “Make in India for the globe“. As our global network of Frigaters provides virtually limitless capacity, and through our IoT enabled platform your parts go directly into production. By digitally and technologically enabling “the silent pillars of the economy” MSME and SME manufacturing industries, we are able to tap the huge potential for manufacturing to bring the best results for our clients.

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

- Quality Testing

Quality Testing Standards for CNC Turning Services

To measure the roundness of cylindrical features, ensuring they meet tolerance requirements.

To check internal surfaces for flatness, critical for sealing and assembly purposes.

To identify burrs or sharp edges that may affect assembly or safety.

To ensure that complex profiles (e.g., contours, curves) conform to design specifications.

To check the topography and texture of the surface, ensuring it meets the required specifications for function or aesthetics.

To verify that the surface hardness depth meets the required specifications for wear resistance.

To measure internal stresses that could lead to deformation or failure during or after machining.

To verify grain structure, inclusions, and material consistency, ensuring the part meets performance requirements.

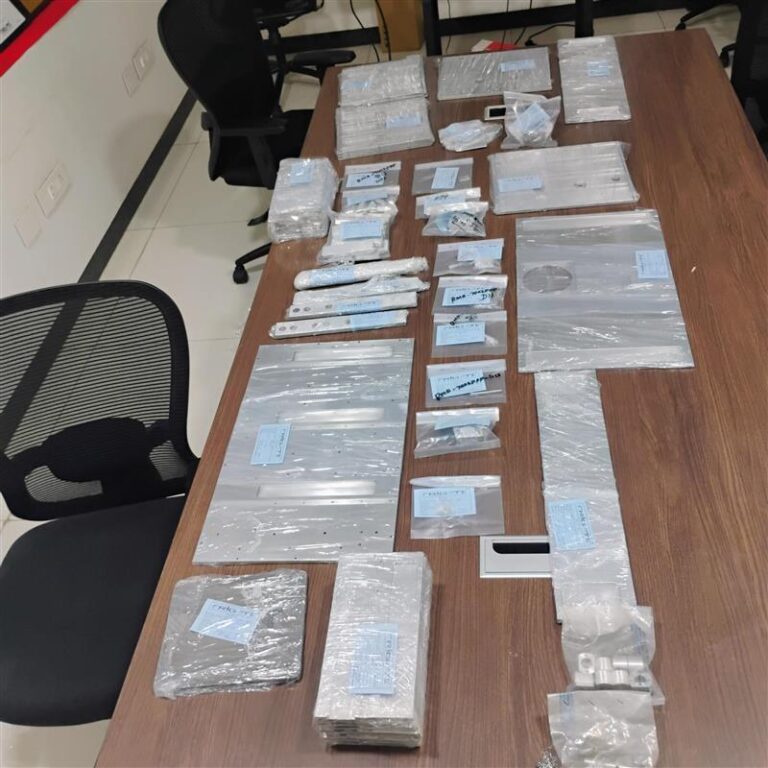

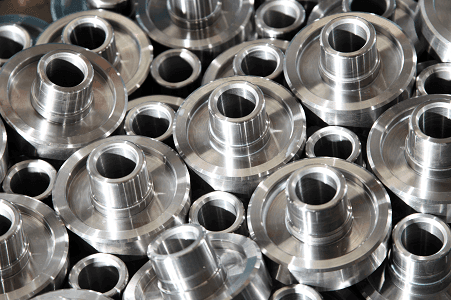

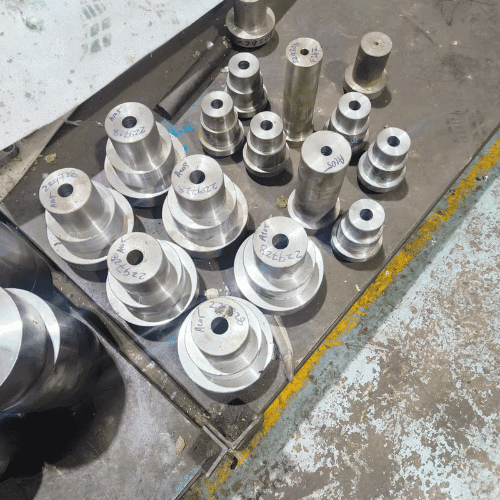

- Product Gallery

Turned CNC Parts for Food Processing

We produce close-tolerance shafts, couplings, flanges, and threaded fittings tailored for sanitary assemblies. Explore samples engineered for performance in mixers, conveyors, and filling systems.

Other Industries We Serve

We deliver machining support across sectors that require consistency, material reliability, and tight dimensional control.

- Solid Progress

Our Manufacturing Metrics

Frigate brings stability, control, and predictable performance to your sourcing operations through a structured multi-vendor system.

2.8X

Sourcing Cycle Speed

Frigate’s pre-qualified network shortens decision time between RFQ and PO placement.

94%

On-Time Delivery Rate

Structured planning windows and logistics-linked schedules improve project-level delivery reliability.

4X

Multi-Part Consolidation

We enable part family batching across suppliers to reduce fragmentation.

22%

Quality Rejection Rate

Multi-level quality checks and fixed inspection plans lower non-conformities.

30%

Procurement Costs

Optimized supplier negotiations and bulk order strategies reduce your overall sourcing expenses.

20%

Manual Processing Time

Automation of sourcing and supplier management significantly reduces time spent on manual tasks.

Get Clarity with Our Manufacturing Insights

- FAQ

Having Doubts? Our FAQ

Check all our Frequently Asked Questions in CNC Turning

Frigate uses synchronized chucking with low-pressure clamping to avoid distortion during turning of thin-walled parts like filter sleeves and drum inserts. Tool paths are optimized with shallow depth passes and radial spring passes to stabilize geometry. Real-time probing confirms wall thickness along critical zones, and every pass is monitored using torque and deflection parameters. This process ensures concentricity and roundness even on high-aspect-ratio forms with minimal wall support.

For parts like pump sleeves, pipe connectors, and valve bodies, Frigate applies finish turning using wiper inserts and high-speed contouring cycles. We achieve Ra values below 0.8 µm using controlled feed rates, verified insert geometry, and minimal coolant contamination. Surface profilometers validate smoothness, especially on contact surfaces that must resist microbial buildup. This helps ensure food safety while supporting compliance with 3-A and FDA guidelines.

Frigate sets machine-level repeatability through closed-loop tool offset correction, pre-set tool life tracking, and automated part ejection. Turned parts like spindles, fasteners, and auger connectors are measured with in-line gauging to confirm OD and bore tolerances. Part drift data is logged across shifts, and machines receive auto-calibration after cycle counts. This guarantees dimensional stability in bulk orders for OEM food lines and filling systems.

Frigate integrates checkpoints during rough and finish turning to inspect groove depth, chamfer consistency, and thread finish. Areas exposed to product flow, like sealing grooves and mating faces, are validated using shadow graph comparators and surface gauges. Operators follow setup sheets with clear QA hold points tied to drawing tolerances. Every part with a sealing or contact surface gets visual and dimensional approval before final packing.

Frigate ties raw material batches to finished parts using part ID labels and barcoded job sheets. Stainless and polymer stocks come with heat numbers, compliance tags (like RoHS or EC 1935/2004), and supplier documentation. These records are stored with each part program and inspection file. Customers receive a full material trace file that includes origin, mechanical properties, and food contact compliance. This supports downstream audits and regulatory checks in global food markets.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Global Sales Office

818, Preakness lane, Coppell, Texas, USA – 75019

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- Texas, USA