- Rapid Manufacturing

CNC Machining Services in Pennsylvania

We manufacture high-accuracy components with fiber optic sensors that track thermal displacement and ensure dimensional stability. Upload your CAD file to get an instant quote and complete your order in just 5 minutes.

- Satisfied Overseas Customers

Excellence You Can Trust

Trusted by Fortune 500 companies for high-precision CNC machining, tight tolerances, and superior quality.

Our Clients

Trusted by Engineers and Purchasing Leaders

- Instant Quotes

Quote in Seconds - Parts in Days

We control spindle torque vectors to stabilize cutting engagement, reducing vibration-induced errors. This ensures consistent dimensions for parts delivered within 7 days

- Get instant quotes

- Get instant DFM feedback

- Online quote and order management

- Project Management

- Our Services

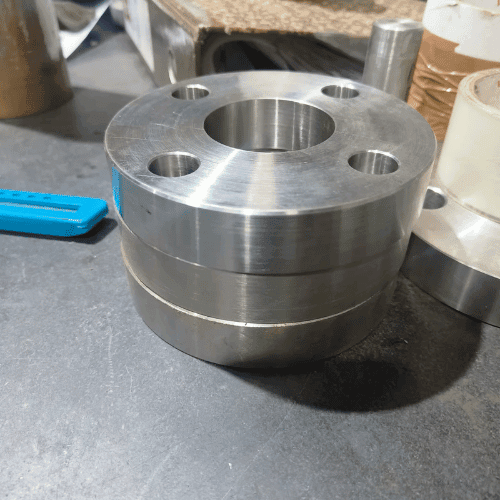

Online CNC Machining Service in Pennsylvania

Get high-precision CNC machined parts online with fast turnaround and cost-effective pricing.

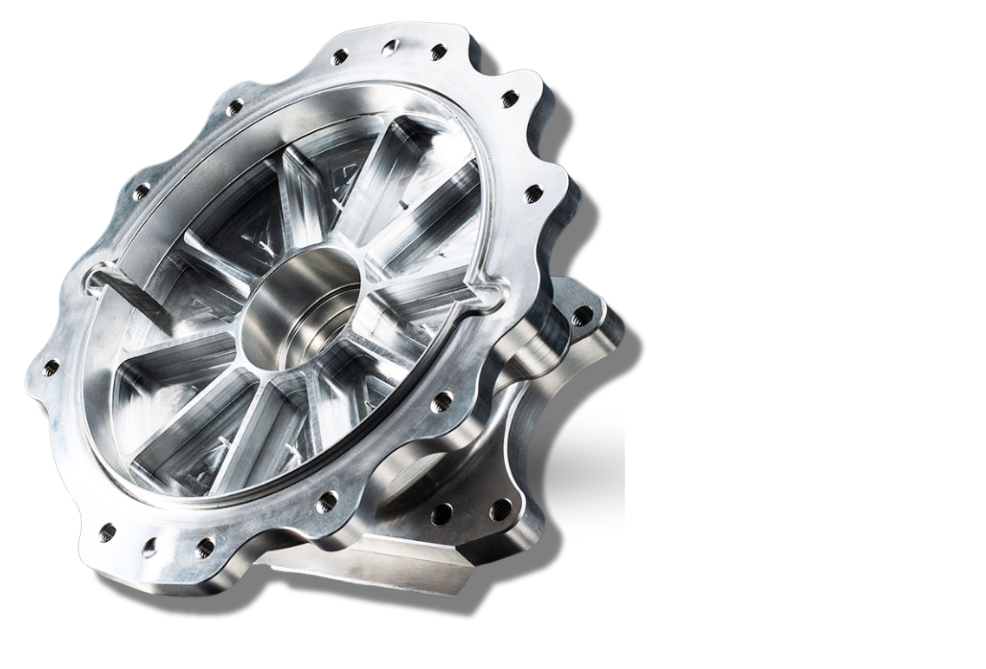

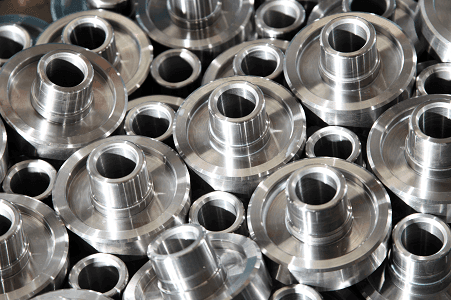

CNC Milling

Ultra-fine CNC milling employs adaptive feed rate modulation, low-pressure coolant delivery, and controlled chip evacuation to minimize surface defects.

- Handle tough materials with spindle power up to 30 kW

- Free design feedback with every quote

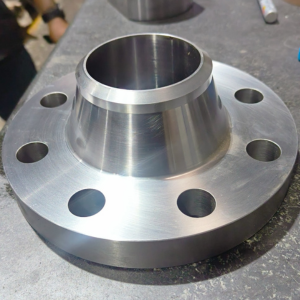

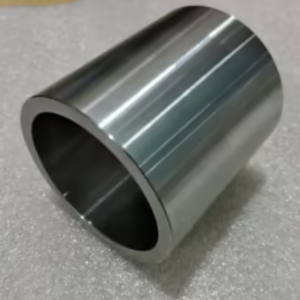

CNC Turning

High-stability CNC turning integrates torque-sensing spindles, active vibration damping, and multi-axis position tracking to ensure precise feature alignment.

- Complex cylindrical parts up to ⌀500mm

- Bar feeding feature for faster, continuous production

- Surface Finish

Flawless Finishes for CNC Machining Parts in Pennsylvania

We achieve superior surface finishes using deep cryogenic tempering, stabilized austenite conversion, and controlled polishing processes to reduce micro-cracks.

Anodizing

Give your aluminum parts a tough, corrosion-resistant shield with anodizing, reaching surface hardness up to HV 500, while enhancing electrical insulation and durability.

Mechanical Finishing

Smooth out imperfections and refine surfaces to Ra 0.2 µm or better with mechanical finishing techniques like grinding, polishing, and bead blasting.

Heat Treatment

Boost material strength and hardness by heat treating parts at temperatures up to 1100°C, ensuring they meet the mechanical demands of your application.

Electroplating

Add protective or functional metal coatings with electroplating, delivering consistent layers as precise as ±2 µm for improved corrosion resistance and conductivity.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

- We export to 12+ countries

Frigate’s Global Presence

Frigate takes pride in facilitating “Make in India for the globe“. As our global network of Frigaters provides virtually limitless capacity, and through our IoT enabled platform your parts go directly into production. By digitally and technologically enabling “the silent pillars of the economy” MSME and SME manufacturing industries, we are able to tap the huge potential for manufacturing to bring the best results for our clients.

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

- Transparent Pricing

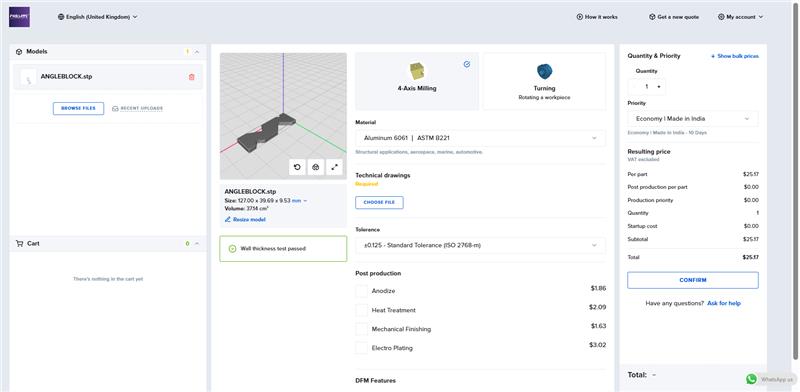

Instant Online Quote for CNC Machining Services

Our approach maps stress-strain responses and phase transformation behavior to enhance material performance predictions. These insights enable fast, data-driven cost calculations for CNC machining services.

- Price updates are made in real time as you change materials, machining methods, etc.

- No hidden costs. Our instant quotes are not just indications but the actual price and include shipping and customs up front.

- Quote to Delivery

Quick and Clear Steps to Your Order

Everything moves smoothly from pricing to shipment, so you get high-quality parts without delays.

Upload CAD File

Obtain a precise and competitive quote instantly to empower your decision-making.

- Detailed cost breakdown

- Various materials and finish choices

- Market-driven unbeatable pricing

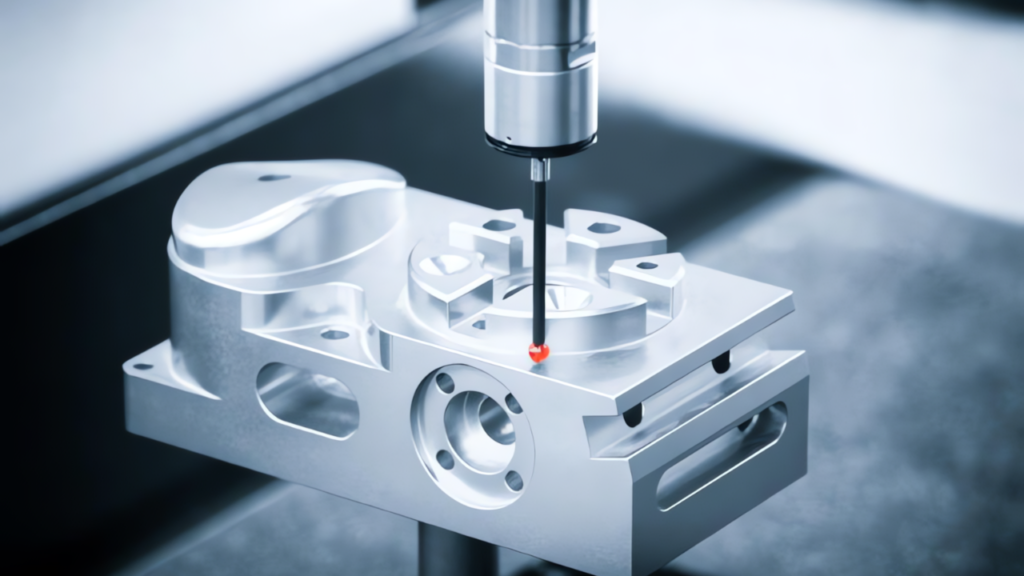

Manufacturing Begins

Transform your designs into reality with our state-of-the-art CNC production capabilities.

- Advanced machinery

- Scalable production support

- Live updates from the production floor

Thorough Inspection

Each part is checked to match exact specifications before moving forward.

- High-tech dimensional verification

- Surface finishing and coating checks

- Batch-wise documentation

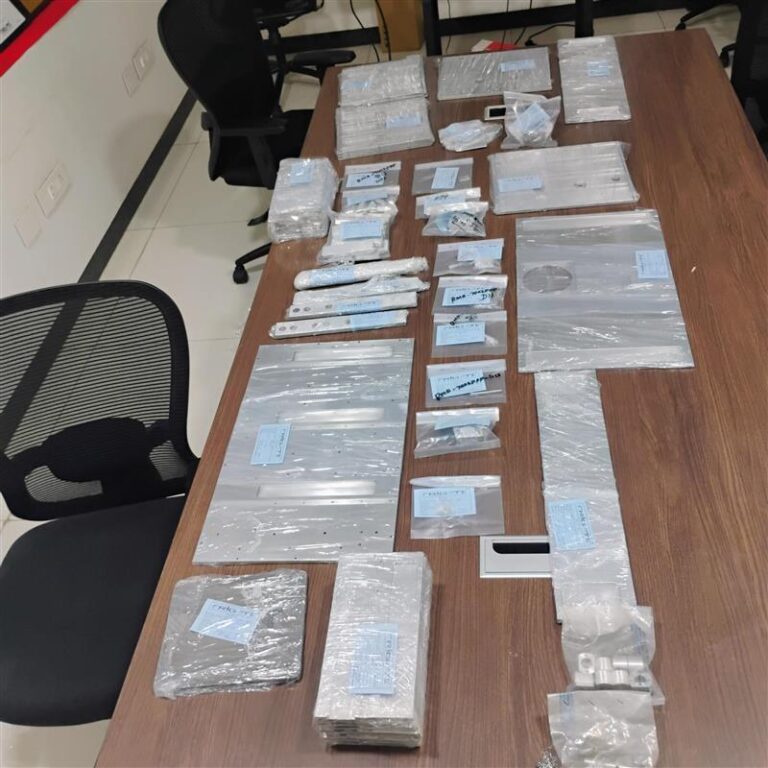

Safe & Timely Dispatch

Receive your machined parts promptly and in perfect condition.

- Multiple shipping options

- Secure packaging

- Real-time tracking during every transit

- Machining Materials

Different Materials for CNC Machining

We rely on high-efficiency vapor chambers and thermal interface materials to control heat distribution in aluminum and magnesium parts. Adaptive spindle positioning maintains dimensional accuracy in detailed designs.

Aluminum 6061

- Density - 2.7 g/cm³

- Tensile Strength - 310 MPa

- Yield Strength - 276 MPa

- Hardness (Brinell) - 95 HB

- Excellent corrosion resistance, good machinability, and heat treatable

Used in aerospace, automotive, and electronics for components like aircraft structures, bicycle frames, and heat sinks due to its lightweight and strength.

Aluminum 7075

- Density - 2.81 g/cm³

- Tensile Strength - 572 MPa

- Yield Strength - 503 MPa

- Hardness (Brinell) - 150 HB

- High fatigue resistance but limited weldability

Commonly used in aerospace, defense, and sporting goods for aircraft wings, firearm components, and high-performance bicycle parts requiring high strength.

Aluminum 7050

- Density - 2.81 g/cm³

- Tensile Strength - 572 MPa

- Yield Strength - 503 MPa

- Hardness (Brinell) - 150 HB

- High fatigue resistance but limited weldability

Commonly used in aerospace, defense, and sporting goods for aircraft wings, firearm components, and high-performance bicycle parts requiring high strength.

Stainless Steel 304

- Density - 8.0 g/cm³

- Tensile Strength - 515 MPa

- Yield Strength - 205 MPa

- Hardness (Brinell) - 201 HB

- High corrosion resistance, non-magnetic, and good formability

Preferred in food processing, medical, and chemical industries for tanks, surgical tools, and piping systems due to its hygiene and corrosion resistance.

Stainless Steel 440 - Carbon

- Density - 7.8 g/cm³

- Tensile Strength - 760 MPa

- Yield Strength - 450 MPa

- Hardness (Rockwell C) - 56-60 HRC

- High hardness, excellent wear resistance, and corrosion resistance

Used in cutting tools, bearings, valves, and surgical instruments where extreme hardness and durability are required.

Stainless Steel 416

- Density - 7.7 g/cm³

- Tensile Strength - 585 MPa

- Yield Strength - 275 MPa

- Hardness (Brinell) - 262 HB

- Free-machining stainless steel with good strength

Ideal for automotive, firearms, and industrial applications, including gears, bolts, and shafts requiring high machinability.

Steel 1018

- Density - 7.87 g/cm³

- Tensile Strength - 440 MPa

- Yield Strength - 370 MPa

- Hardness (Brinell) - 126 HB

- Excellent weldability and machinability

Used in automotive, machinery, and construction for shafts, pins, and fasteners where moderate strength and cost efficiency are key.

Steel 4140

- Density - 7.85 g/cm³

- Tensile Strength - 655 MPa

- Yield Strength - 415 MPa

- Hardness (Rockwell C) - 28-32 HRC

- High strength, toughness, and wear resistance

Widely used in oil & gas, aerospace, and automotive for gears, crankshafts, axles, and high-load machine components requiring extreme durability.

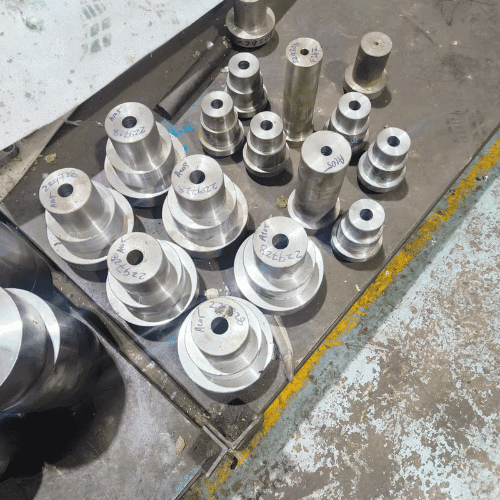

- CNC Machining Parts

CNC Machining Parts in Pennsylvania

We utilize flexure-guided stages, servo-driven actuators, and dynamic stabilization systems to ensure precise positioning. Browse our precision-crafted solutions for demanding manufacturing applications.

- One Stop Solution

End-to-End CNC Machining Solutions in Pennsylvania

Our system integrates magnetic levitation stages, fiber-optic encoders, and adaptive error compensation to reduce positional drift during multi-axis machining.

We assess cutting force variations, feed rate optimization data, and coolant flow efficiency to deliver instant online pricing for complex designs.

Our process uses digital holography, thermal wave analysis, and ultrasonic backscattering for high-accuracy defect identification.

- Optimized Workflow

From CNC Rapid Prototyping to Production in Pennsylvania

Frigate offers fast and precise CNC machining, from rapid prototyping to full-scale production, ensuring high-quality parts with quick turnaround times.

Rapid Prototyping

We apply plasma electrolytic oxidation alongside CNC machining to produce prototypes with dense oxide layers, improved hardness, and excellent thermal stability.

- Instant quotes

- Instant DFM feedback

- Online quote and order management

- Live delivery tracking

Our team examines crack initiation points, slip system activation, and lattice distortion effects to enhance component durability in demanding applications.

Production Orders

We enhance surface integrity in precision parts using electrochemical polishing with dynamic voltage modulation to manage material dissolution rates.

- Dedicated project managers in your time zone

- Application engineers focused on DFM cost optimizations

- First Article Inspection (FAI) for quality assurance

- Supply chain support for materials and on-time delivery

Our system combines AI-driven scheduling algorithms with real-time equipment status monitoring to maximize resource efficiency throughout production shifts.

- Trusted Solutions

CNC Machining Solutions in Pennsylvania that You Can Trust

Our system combines magnetic clamping with pressure-regulated vacuum stabilization to enhance part stability during machining. Optical profilometry assesses thin-film surface consistency.

- Ultra-Tight Tolerances (±0.005mm)

- 5-Axis Machining for Complex Designs

- High-Speed Spindles (Up to 60,000 RPM)

- Adaptive Feed Rate Optimization

- Rigid Fixturing & Workholding

- Manufacturing Optimization

Get Started with Our CNC Machining Services

Our solution employs white-light interferometry, infrared thermography, and profilometry to identify surface discontinuities and ensure dimensional accuracy in intricate components.

Cryogenic Cooling Systems

Liquid nitrogen cooling enhances tool life, suppresses heat buildup, and prevents thermal distortion in heat-sensitive materials.

Helical Tool Path Optimization

Adaptive toolpath strategies control chip load distribution, improving cutting efficiency and extending tool life.

Dual-Spindle Synchronization

Paired spindles operate in tandem to machine symmetrical parts simultaneously, improving production efficiency.

- FAQ

Having Doubts? Our FAQ

Check all our Frequently Asked Questions in CNC Machining

Frigate employs capacitance-based sensor feedback, thermal drift compensation, and adaptive axis calibration to achieve micron-level accuracy. These advanced systems ensure precise geometric alignment and minimal positional error in complex part profiles.

Frigate applies phase-change cooling materials, micro-channel heat exchangers, and vortex tube cooling to maintain stable temperatures. These methods control thermal gradients, reducing material distortion in high-precision components.

Frigate uses piezo-actuated tool holders, harmonic spindle balancing, and hydrostatic bearing systems to reduce vibration and maintain tool rigidity. This enhances cutting performance in challenging materials like Inconel, titanium, and hardened steels.

Frigate uses interferometric laser systems, atomic force microscopy, and pulse thermography to detect micro-surface deviations and dimensional inconsistencies. These techniques ensure parts meet exact specifications in aerospace, medical, and automotive applications.

Frigate applies toolpath optimization algorithms, dynamic feed rate modulation, and AI-driven cutting strategies to improve cycle times. These methods enhance accuracy while minimizing material waste in intricate designs.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany