CNC Machining Services for Dental & Orthodontics

Frigate manufactures precision-machined components for dental and orthodontic OEMs using high-speed, multi-axis CNC systems. Our parts meet demanding hygiene, dimensional, and surface quality standards required by global dental equipment suppliers.

Our Clients

- Production Efficiency

Advantages of Our CNC Machining Services

Our workflows support low-batch prototyping and high-volume production with consistent tolerance control across titanium and stainless grades.

Laser Micro-Engraving

We machine intricate ID marks and anti-counterfeit codes on implantable-grade components with sub-25 micron precision.

Micro-Machined Grooves

Tactile grip grooves for orthodontic pliers and scalers are machined with radial symmetry to improve handling during procedures.

Thermal Distortion Reduction

Material-specific compensation methods maintain dimensional accuracy during dry or coolant-assisted machining cycles.

- Machining Methodology

Our CNC Machining Process

We apply hybrid CAM strategies that combine high-speed tool paths, synchronized rotation, and in-cycle probing for precision across tight-tolerance dental features.

Advanced algorithms optimize tool paths, minimizing tool wear, reducing cycle times, and improving surface finishes. This involves strategically planning the sequence of movements and cuts to enhance efficiency.

Modern CNC machines often utilize 5-axis or even 6-axis capabilities, allowing for complex geometries and intricate shapes. This reduces the need to reposition the part, ensuring higher accuracy and a more refined finish.

CNC machines may integrate adaptive cutting strategies, where cutting conditions (speed, feed, depth of cut) adjust dynamically based on real-time sensor feedback or cutting force monitoring. This helps prevent tool breakage and ensures optimal material removal rates.

Specialized techniques like high-speed machining enable faster spindle speeds and advanced feed rates. This increases material removal rates while maintaining fine tolerances and reducing thermal distortion.

Some CNC setups incorporate in-process measuring systems (like laser scanners or probe-based systems) to check the part’s dimensions as it’s being machined. These systems can send real-time data back to the machine, allowing for automatic adjustments during production.

CNC machines with automated tool changers enhance efficiency by switching tools automatically without operator intervention. This allows for uninterrupted multi-operation machining without downtime, improving productivity in complex jobs with several cutting tools.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

- Surface Finish Expertise

Fine Surface Outcomes for Dental Machined Parts

We achieve ultra-smooth finishes critical for intraoral tools, ensuring biocompatibility and reducing microbial retention.

Anodizing

Give your aluminum parts a tough, corrosion-resistant shield with anodizing, reaching surface hardness up to HV 500, while enhancing electrical insulation and durability.

Mechanical Finishing

Smooth out imperfections and refine surfaces to Ra 0.2 µm or better with mechanical finishing techniques like grinding, polishing, and bead blasting.

Heat Treatment

Boost material strength and hardness by heat treating parts at temperatures up to 1100°C, ensuring they meet the mechanical demands of your application.

Electroplating

Add protective or functional metal coatings with electroplating, delivering consistent layers as precise as ±2 µm for improved corrosion resistance and conductivity.

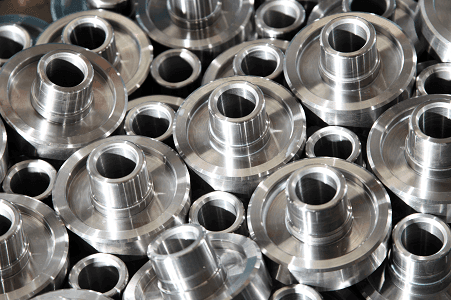

Our Machined Products

We support your production needs with CNC-machined parts, subassemblies, and performance-critical components.

- Our Capabilities

Digital CNC Machining for Dental Applications

Get machined parts with production-grade outcomes and access to cleanroom-compliant secondary operations.

CNC Milling

High-accuracy milling for crowns, bridges, abutments, and tray components using rigid setups and process-monitored paths.

- High feed rates maintained for zirconia and CoCr blanks

- Free manufacturability checks before quote confirmation

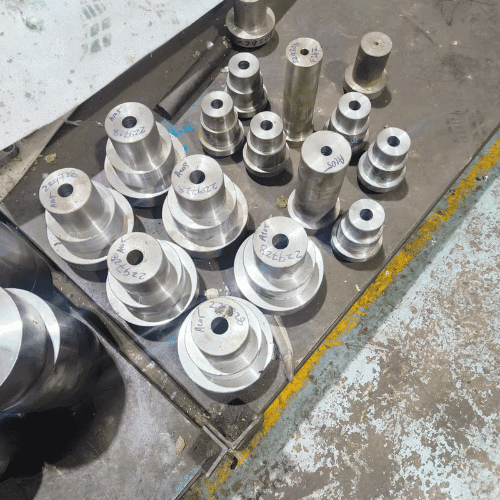

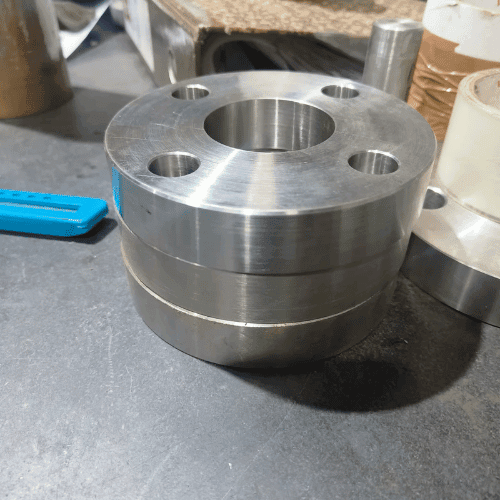

CNC Turning

We support turned components for dental implant systems, including screw-retained parts and mating connectors.

- Tight concentricity maintained on threaded shafts

- Tool changers calibrated for repetitive runs

- Material Focus

CNC Machining Materials for Dental Components

We work with medical-grade materials engineered for biocompatibility and cleanability. These materials suit both patient-facing and equipment-facing components.

- Medical-grade titanium Ti-6Al-4V used for abutments and root posts

- PEEK and PPSU used for lightweight intraoral instruments

- 316L stainless for reusable trays, syringes, and drill guides

A2 Tool Steel is a high-carbon, high-chromium steel known for its toughness and wear resistance. It’s ideal for producing durable, high-strength parts that can withstand heavy use.

Aluminum is a lightweight, corrosion-resistant metal with good machinability. Because of its strength-to-weight ratio, it’s commonly used in aerospace, automotive, and various industrial applications.

Brass is a copper-zinc alloy known for its machinability and corrosion resistance. It’s used for components requiring precise detailing and good mechanical properties.

Bronze is a copper-tin alloy with excellent wear resistance and strength. It’s often used for bushings, bearings, and other friction-prone components.

Cast Iron is known for its high wear resistance and machinability. It’s used in heavy-duty applications such as machinery parts and engine components.

Copper offers excellent thermal and electrical conductivity. It’s used in applications requiring heat dissipation or electrical conductivity, such as electronic components.

Steel is a versatile material known for its strength and durability. It’s used in various applications, from construction to automotive parts.

Titanium is a lightweight, high-strength metal with excellent corrosion resistance. It’s used in aerospace, medical implants, and high-performance engineering applications.

Stainless Steel offers high corrosion resistance and strength. It’s widely used in applications ranging from kitchen equipment to industrial machinery.

Zinc is a ductile and corrosion-resistant metal known for its excellent machinability, especially in its alloy forms. It's often used for components requiring intricate details, good surface finish, and precise dimensions, commonly found in automotive, hardware, and electrical applications.

- Process Integration

Key Execution Points

Our execution process supports accuracy, clean surface quality, and production repeatability from prototyping to regulated batch production.

- Serialized inspection traceability for implantable components

- Conformance-ready CAD-CAM loopback with revision control

- Dedicated process routing for ISO 13485 readiness

- Tool life monitoring tied to quality thresholds

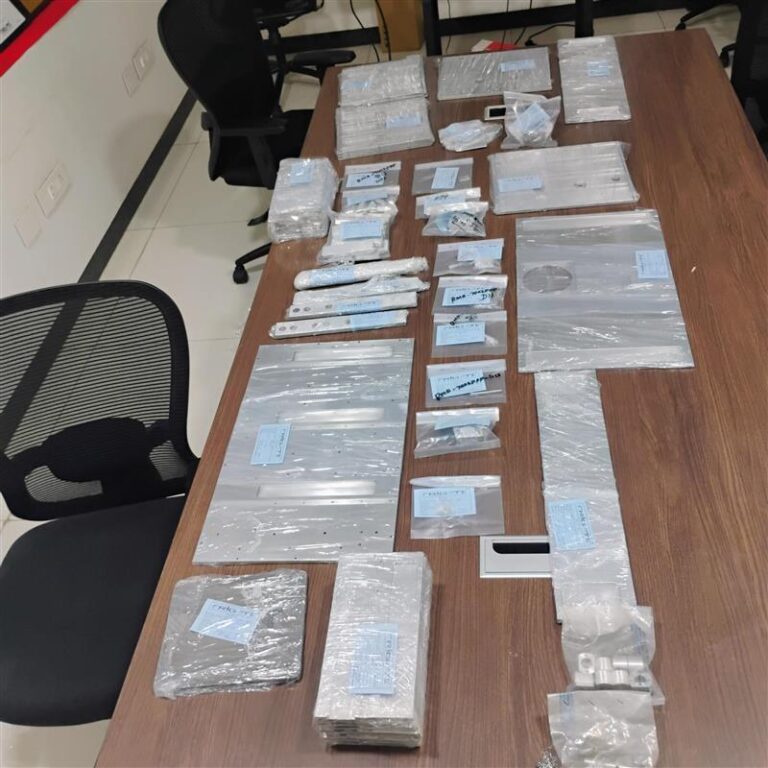

- Cleanroom-ready packaging options

- Compliance Readiness

Compliance Standards for Dental CNC Machining Service

Frigate’s dental part machining workflows meet strict industry and regulatory expectations for traceability, surface quality, and hygiene. Our compliance process follows ISO-aligned traceability, validated machining plans, and sterile handling preparation. All workflows support batch-based documentation and downstream cleanroom compatibility.

- Document control integrated with part routing

- Inspection templates matched to dental tolerance classes

- Audit logs available for supplier qualification

Machining aligned to medical device quality management requirements.

Processes structured to support QSR-compliant manufacturing.

All materials sourced comply with restricted substance regulations.

Supports CE-markable device part production under EU MDD/MDR.

General quality system applied across all machining workflows.

Machined components meet EU chemical safety requirements.

Electromechanical dental component safety documentation ready.

- We export to 12+ countries

Frigate’s Global Presence

Frigate takes pride in facilitating “Make in India for the globe“. As our global network of Frigaters provides virtually limitless capacity, and through our IoT enabled platform your parts go directly into production. By digitally and technologically enabling “the silent pillars of the economy” MSME and SME manufacturing industries, we are able to tap the huge potential for manufacturing to bring the best results for our clients.

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

- Testing & Metrology

Quality Testing Standards for Dental CNC Machining

To measure the roundness of cylindrical features, ensuring they meet tolerance requirements.

To check internal surfaces for flatness, critical for sealing and assembly purposes.

To identify burrs or sharp edges that may affect assembly or safety.

To ensure that complex profiles (e.g., contours, curves) conform to design specifications.

To check the topography and texture of the surface, ensuring it meets the required specifications for function or aesthetics.

To verify that the surface hardness depth meets the required specifications for wear resistance.

To measure internal stresses that could lead to deformation or failure during or after machining.

To verify grain structure, inclusions, and material consistency, ensuring the part meets performance requirements.

- Application Showcase

CNC Machining Parts

We maintain micron-grade accuracy using closed-loop machining, feedback-controlled spindles, and thermal drift monitoring. Explore actual dental components manufactured for high-cycle use and patient-facing reliability.

Other Industries We Serve

We deliver machining support across sectors that require consistency, material reliability, and tight dimensional control.

- Solid Progress

Our Manufacturing Metrics

Frigate brings stability, control, and predictable performance to your sourcing operations through a structured multi-vendor system.

2.8X

Sourcing Cycle Speed

Frigate’s pre-qualified network shortens decision time between RFQ and PO placement.

94%

On-Time Delivery Rate

Structured planning windows and logistics-linked schedules improve project-level delivery reliability.

4X

Multi-Part Consolidation

We enable part family batching across suppliers to reduce fragmentation.

22%

Quality Rejection Rate

Multi-level quality checks and fixed inspection plans lower non-conformities.

30%

Procurement Costs

Optimized supplier negotiations and bulk order strategies reduce your overall sourcing expenses.

20%

Manual Processing Time

Automation of sourcing and supplier management significantly reduces time spent on manual tasks.

Get Clarity with Our Manufacturing Insights

- FAQ

Having Doubts? Our FAQ

Check all our Frequently Asked Questions in CNC Machining

Frigate applies dry machining or coolant systems with medical-grade lubricants to prevent contamination during part production. We maintain dedicated tooling for titanium and stainless to avoid cross-material debris. Each machined part undergoes ultrasonic cleaning and Class 10,000 air-blow-off stations before packing. This prevents biofilm buildup and reduces reprocessing time for OEMs. Our workflow meets hygiene and cleanliness standards essential for patient-facing components.

Frigate uses synchronized CNC turning and helical interpolation for accurate thread profiles on titanium and stainless implants. We validate each thread pitch and angle using profile gauges and optical comparators. To prevent microburr formation, we apply minimum chip load cutting with multi-pass thread generation. As a result, the threads engage smoothly with mating parts while ensuring biocompatibility and repeat assembly integrity.

Frigate minimizes tool-to-part heat transfer by using high-speed, low-force cutting strategies and optimized spindle cooling. During extended runs, we use staged roughing and controlled finishing paths to stabilize temperatures. Materials like PPSU and zirconia receive shorter cycle passes with dwell time management. This ensures dimensional stability in features under 0.5 mm, commonly seen in scalers, tips, or brackets.

Frigate links each part with a unique traceability code embedded either through laser marking or QR labeling. Our MES (Manufacturing Execution System) records all parameters including material batches, tool paths, and inspection logs. Real-time syncing with quality records enables OEMs to retrieve any part’s data instantly. This system supports ISO 13485 traceability requirements and simplifies audit readiness for regulatory compliance.

Frigate performs multi-stage quality checks starting from in-process probing to post-machining CMM verification. We use optical vision systems to inspect submillimeter features and edge radii on dental tips or implant threads. Surface roughness is measured using contact and non-contact testers to meet Ra values under 0.4 µm. All inspections are logged against serialized part IDs, ensuring full quality documentation for each production lot.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany