Advanced Polymer Dielectric Insulation for Automotive OEM & Aftermarket Applications

Designed to maintain dielectric strength above 150°C, resist fluid ingress, and prevent failure modes like oxidation, micro-cracking, and electrical treeing in automotive assemblies.

Frigate Ensures Reliability Through Advanced Engineering Solutions

Real-Time Electrical Monitoring

Components incorporate embedded sensor ports for real-time force and vibration monitoring during CNC turning. This enables early detection of cutting anomalies and supports condition-based maintenance without compromising part dimensional accuracy or material properties.

Comprehensive EMI Shielding

Multi-layer shields of copper braid, aluminum foil, and conductive polymers suppress EMI across automotive frequencies. Optimized grounding and terminations prevent common-mode currents, preserving signal quality for critical vehicle systems.

Enhanced Mechanical Flexibility

Stranded conductors with elastomeric sheaths absorb vibration, bending, and torsion stresses typical in EVs and autonomous vehicles. This reduces fatigue cracks and abrasion, validated by accelerated mechanical endurance testing.

Our Clients

Trusted by Engineers and Purchasing Leaders

- Satisfied Overseas Customers

Excellence You Can Trust

Trusted by Fortune 500 companies for high-precision CNC machining, tight tolerances, and superior quality.

Achieve Real-Time Defect Prevention Through Precision Manufacturing

In-line optical and electrical inspection combined with AI-driven analytics enable immediate detection of deviations in conductor geometry, insulation thickness, and surface defects during production.

Deploy continuous real-time optical and electrical sensors that identify dimensional and surface anomalies instantly, ensuring early intervention before defects propagate.

Utilize AI-powered process monitoring to trigger corrective actions dynamically, maintaining strict dimensional and electrical consistency throughout production batches.

Maintain rigorous adherence to automotive industry standards by preventing latent defects and ensuring every unit meets exacting specifications.

Enable Seamless Integration in High-Density Electrical Architectures

Custom assemblies are engineered with precise impedance matching and connector compatibility to reduce signal reflection and insertion loss within confined spaces.

Tailor conductor layout and shielding to control impedance and minimize electromagnetic coupling in dense vehicle harness configurations.

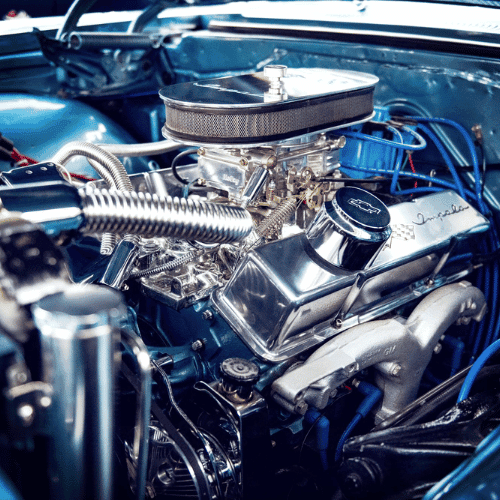

Design for bend radius constraints and retention forces to support easy installation in tight engine compartments and electronic modules.

Position coolant nozzles and optimize cutting parameters to dissipate heat effectively and preserve dimensional stability during high-speed CNC turning.

Ensure Compliance with High-Voltage and Cybersecurity Standards

Advanced dielectric barriers and extended creepage distances provide protection against high-voltage stresses and transient voltage spikes in EV systems.

Apply reinforced insulation and creepage design to withstand electrical stress typical of electric vehicle powertrains.

Integrate shielding and construction techniques to mitigate electromagnetic eavesdropping and cyber-physical tampering risks.

Meet emerging safety and cybersecurity requirements critical to autonomous and connected vehicle platforms.

Our Machined Products

We support your production needs with CNC-machined parts, subassemblies, and performance-critical components.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

- We export to 12+ countries

Frigate’s Global Presence

Frigate takes pride in facilitating “Make in India for the globe“. As our global network of Frigaters provides virtually limitless capacity, and through our IoT enabled platform your parts go directly into production. By digitally and technologically enabling “the silent pillars of the economy” MSME and SME manufacturing industries, we are able to tap the huge potential for manufacturing to bring the best results for our clients.

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

- Solid Progress

How You Benefit with Us

Frigate brings stability, control, and predictable performance to your sourcing operations through a structured multi-vendor system.

2.8X

Sourcing Cycle Speed

Frigate’s pre-qualified network shortens decision time between RFQ and PO placement.

94%

On-Time Delivery Rate

Structured planning windows and logistics-linked schedules improve project-level delivery reliability.

4X

Multi-Part Consolidation

We enable part family batching across suppliers to reduce fragmentation.

22%

Quality Rejection Rate

Multi-level quality checks and fixed inspection plans lower non-conformities.

30%

Procurement Costs

Optimized supplier negotiations and bulk order strategies reduce your overall sourcing expenses.

20%

Manual Processing Time

Automation of sourcing and supplier management significantly reduces time spent on manual tasks.

Other Industries We Serve

We deliver machining support across sectors that require consistency, material reliability, and tight dimensional control.

Get Clarity with Our Manufacturing Insights

Frigate follows a multi-layered approach to quality assurance that aligns with global standards like IATF 16949 and ISO 9001. Each production line is supported by real-time data collection, SPC (Statistical Process Control), and in-line visual inspection systems to detect deviations early. For mission-critical components like engine brackets or suspension mounts, Frigate uses advanced metrology tools, 3D scanning, and CMM inspection. Frigate also conducts PPAP submissions, first article inspections, and pilot lot approvals to ensure consistency from the first piece to the last.

Frigate maintains a structured ECN (Engineering Change Notice) process, supported by integrated CAD/CAM platforms and modular tooling design. Whether it’s a minor design tweak in a stamped bracket or a critical geometry update in a CNC-machined housing, Frigate reviews the impact across tooling, process flow, and downstream logistics before implementation. This prevents production halts and compliance issues. Frigate’s in-house engineering team collaborates closely with clients to simulate the effects of changes before rollout, ensuring validation and compliance checks are in place.

Frigate implements full digital traceability for every part it produces—starting from raw material heat numbers to finished component serialization. This is especially valuable for Tier 1 and Tier 2 suppliers needing to meet regulatory mandates in Europe, North America, and Asia. Frigate’s MES (Manufacturing Execution System) and ERP integration ensures part-level traceability through barcodes, QR codes, or laser-etched identifiers. In case of a recall or field failure, clients can instantly retrieve complete process, operator, and inspection history.

Frigate understands that not every business needs mass production. For aftermarket brands and niche vehicle platforms, Frigate offers hybrid production setups with dedicated flexible cells, quick-change tooling, and multi-process machines. This minimizes tooling costs and setup time, allowing short production runs without compromising quality or unit economics. Whether it's a discontinued model part or a regional variant with limited demand, Frigate supports customers with scalable production and just-in-time delivery.

Frigate operates under strict data protection and confidentiality protocols that safeguard customer intellectual property throughout the project lifecycle. From the moment CAD files or design documents are received, Frigate restricts access through secure, role-based controls and encrypted file handling systems. All employees involved in sensitive projects are bound by NDAs, and specific production areas are access-controlled to prevent data leakage. Additionally, Frigate does not subcontract without client approval, ensuring end-to-end control.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany