CNC Machining for Renewable Energy (Wind & Solar)

Frigate machines wind turbine components like main shafts, yaw gear assemblies, and rotor hubs using spindle-synchronized probing and multi-station fixturing to maintain ≤0.01 mm circular runout. CMM validation in thermalized inspection cells ensures dimensional uniformity across 5-meter-class batch lengths.

Our Clients

- Precision at Every Stage

CNC Machining for Critical Wind Turbine Components

Frigate delivers ≤0.01 mm circular runout on main shafts, yaw gears, and hubs using spindle-synced probing and CMM-verified multi-axis machining.

Fatigue-Resistant Finishing

Surface roughness of Ra ≤ 0.4 µm is achieved using low-force cutting, cryogenic cooling, and optimized toolpaths, followed by residual stress checks to prevent fatigue crack initiation.

Alloy-Specific Machining

Duplex stainless, 6000/7000-series aluminum, and Ni-Cr-Mo alloys are machined with material-specific parameters to suppress galling, phase shifts, and anisotropic deviations impacting structural and bolted joint performance.

Precision Across Solar Tracker Assemblies

Positional repeatability across 30-meter tracker assemblies is maintained using in-field constraint simulation during machining, ensuring angular alignment, consistent actuator loads, and resistance to seasonal thermally induced creep.

- Step-by-Step Machining Approach

Our CNC Machining Process

The process integrates multi-axis toolpath simulation, real-time spindle feedback, and closed-loop metrology to maintain dimensional integrity in large-diameter and asymmetrical wind turbine parts.

Advanced algorithms optimize tool paths, minimizing tool wear, reducing cycle times, and improving surface finishes. This involves strategically planning the sequence of movements and cuts to enhance efficiency.

Modern CNC machines often utilize 5-axis or even 6-axis capabilities, allowing for complex geometries and intricate shapes. This reduces the need to reposition the part, ensuring higher accuracy and a more refined finish.

CNC machines may integrate adaptive cutting strategies, where cutting conditions (speed, feed, depth of cut) adjust dynamically based on real-time sensor feedback or cutting force monitoring. This helps prevent tool breakage and ensures optimal material removal rates.

Specialized techniques like high-speed machining enable faster spindle speeds and advanced feed rates. This increases material removal rates while maintaining fine tolerances and reducing thermal distortion.

Some CNC setups incorporate in-process measuring systems (like laser scanners or probe-based systems) to check the part’s dimensions as it’s being machined. These systems can send real-time data back to the machine, allowing for automatic adjustments during production.

CNC machines with automated tool changers enhance efficiency by switching tools automatically without operator intervention. This allows for uninterrupted multi-operation machining without downtime, improving productivity in complex jobs with several cutting tools.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

- Surface Finish

Flawless Finishes for CNC Machining Parts

Programmable deburring, adaptive feed-rate milling, and controlled abrasive flow machining are used to maintain Ra and Rz within turbine-grade thresholds. These methods reduce surface stress concentrations and enhance high-cycle fatigue resistance in rotating components.

Anodizing

Give your aluminum parts a tough, corrosion-resistant shield with anodizing, reaching surface hardness up to HV 500, while enhancing electrical insulation and durability.

Mechanical Finishing

Smooth out imperfections and refine surfaces to Ra 0.2 µm or better with mechanical finishing techniques like grinding, polishing, and bead blasting.

Heat Treatment

Boost material strength and hardness by heat treating parts at temperatures up to 1100°C, ensuring they meet the mechanical demands of your application.

Electroplating

Add protective or functional metal coatings with electroplating, delivering consistent layers as precise as ±2 µm for improved corrosion resistance and conductivity.

Our Machined Products

We support your production needs with CNC-machined parts, subassemblies, and performance-critical components.

- Machining Capabilities

Multi-Axis Machining for Complex Renewable Energy Components

Advanced machining for hub plates, turbine shafts, and high-strength alloys using adaptive feed and live tooling capabilities.

CNC Milling

We support hub plate and nacelle component milling with adaptive feed control, multi-axis contouring, and high aspect-ratio cavity generation.

- Spindle setup up to 30 kW with high-pressure through-spindle coolant for carbide tooling.

- Milling of duplex stainless steels and structural alloys like 17-4 PH and Inconel 625.

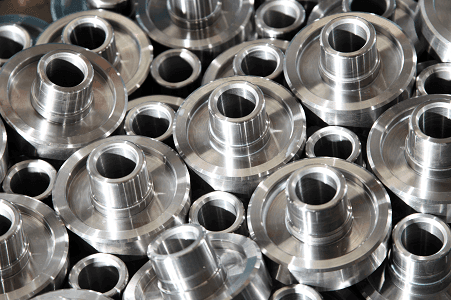

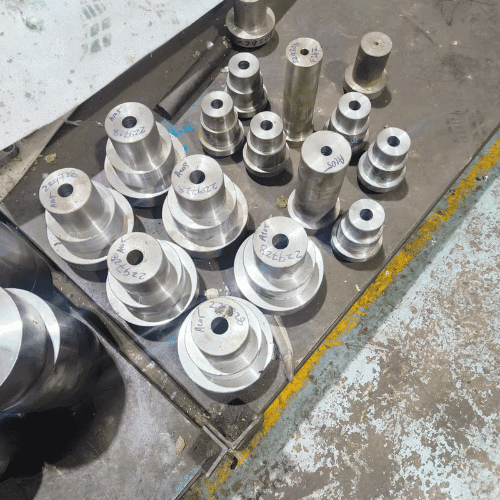

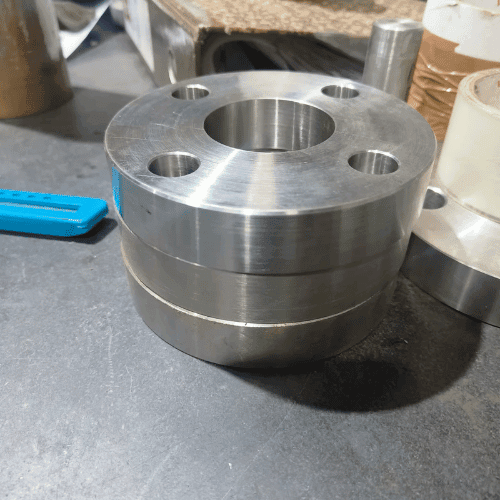

CNC Turning

We machine turbine shaft collars, locking bushings, and solar tracker pivots with advanced CNC turning cycles for critical L/D geometries.

- Turning for diameters from 10 mm to 800 mm.

- Live tooling enables orthogonal slotting, keyways, and angled drilling without secondary operations.

- Material Compatibility

High-Strength Alloys for Demanding Renewable Energy Applications

Turbine hubs, nacelle housings, and solar mountings require metals with high fatigue resistance, thermal stability, and corrosion tolerance. Materials selected for CNC-machined wind and solar parts must endure extreme load variations, UV exposure, and coastal environments.

- Tensile strength over 500 MPa ideal for yaw drives and blade root interfaces

- Thermal expansion coefficient below 15 µm/m°C prevents warping in solar tracking arms

- Machinability rating over 60% reduces tool wear during contour profiling

- Corrosion rate below 0.01 mm/year ensures 20+ years of outdoor performance

A2 Tool Steel is a high-carbon, high-chromium steel known for its toughness and wear resistance. It’s ideal for producing durable, high-strength parts that can withstand heavy use.

Aluminum is a lightweight, corrosion-resistant metal with good machinability. Because of its strength-to-weight ratio, it’s commonly used in aerospace, automotive, and various industrial applications.

Brass is a copper-zinc alloy known for its machinability and corrosion resistance. It’s used for components requiring precise detailing and good mechanical properties.

Bronze is a copper-tin alloy with excellent wear resistance and strength. It’s often used for bushings, bearings, and other friction-prone components.

Cast Iron is known for its high wear resistance and machinability. It’s used in heavy-duty applications such as machinery parts and engine components.

Copper offers excellent thermal and electrical conductivity. It’s used in applications requiring heat dissipation or electrical conductivity, such as electronic components.

Steel is a versatile material known for its strength and durability. It’s used in various applications, from construction to automotive parts.

Titanium is a lightweight, high-strength metal with excellent corrosion resistance. It’s used in aerospace, medical implants, and high-performance engineering applications.

Stainless Steel offers high corrosion resistance and strength. It’s widely used in applications ranging from kitchen equipment to industrial machinery.

Zinc is a ductile and corrosion-resistant metal known for its excellent machinability, especially in its alloy forms. It's often used for components requiring intricate details, good surface finish, and precise dimensions, commonly found in automotive, hardware, and electrical applications.

- Thermal Stability

Key Highlights

CNC machining enables scalable, high-tolerance part production essential for wind turbines and solar equipment. With 5-axis control and micron-level feed rates, it supports both structural and motion-critical parts.

- Machined surface flatness up to 0.01 mm for torque interface reliability

- Supports shaft lengths exceeding 1,200 mm without bending deviation

- Enables tight-fit hole tolerances of ±0.005 mm in high-load areas

- Accommodates low-waste batch runs for blades and inverter housings

- Regulatory Alignment

Compliance and Certification for Renewable CNC Machining

CNC machining for wind and solar energy must meet strict industry-specific standards. These ensure material performance, process control, and environmental responsibility.

- Adheres to sector-specific regulatory frameworks for clean energy hardware production.

- Implements detailed process documentation for traceability and conformity.

- Validates material composition and mechanical properties through batch-level inspections.

- Ensures sustainable practices via routine audits and quality assurance protocols.

We are certified to this international quality management standard, ensuring rigorous control over all machining processes for consistent, high-quality components.

Our machining processes for wind turbine components strictly adhere to this series, covering design, safety, and testing requirements for structural integrity.

We meticulously select and machine materials to relevant ASTM standards, guaranteeing precise chemical composition and mechanical performance for durability.

We meet the detailed dimensional and surface finish specifications critical for specific wind turbine elements, ensuring optimal function.

Our machining operations prioritize GD&T specifications, ensuring precise component fit, assembly, and interchangeability, crucial for complex renewable systems.

We integrate NDT methods like magnetic particle or liquid penetrant inspection to detect internal and surface flaws, ensuring component reliability.

We achieve specified surface finishes during machining, crucial for reducing friction, improving fatigue resistance, and enhancing component longevity in dynamic environments.

- We export to 12+ countries

Frigate’s Global Presence

Frigate takes pride in facilitating “Make in India for the globe“. As our global network of Frigaters provides virtually limitless capacity, and through our IoT enabled platform your parts go directly into production. By digitally and technologically enabling “the silent pillars of the economy” MSME and SME manufacturing industries, we are able to tap the huge potential for manufacturing to bring the best results for our clients.

100,000+

Parts Manufactured

250+

Frigaters

2000+

Machines

450+

Materials

25+

Manufacturing Process

- Quality Standards

Quality Testing for Mold Machining Projects

To measure the roundness of cylindrical features, ensuring they meet tolerance requirements.

To check internal surfaces for flatness, critical for sealing and assembly purposes.

To identify burrs or sharp edges that may affect assembly or safety.

To ensure that complex profiles (e.g., contours, curves) conform to design specifications.

To check the topography and texture of the surface, ensuring it meets the required specifications for function or aesthetics.

To verify that the surface hardness depth meets the required specifications for wear resistance.

To measure internal stresses that could lead to deformation or failure during or after machining.

To verify grain structure, inclusions, and material consistency, ensuring the part meets performance requirements.

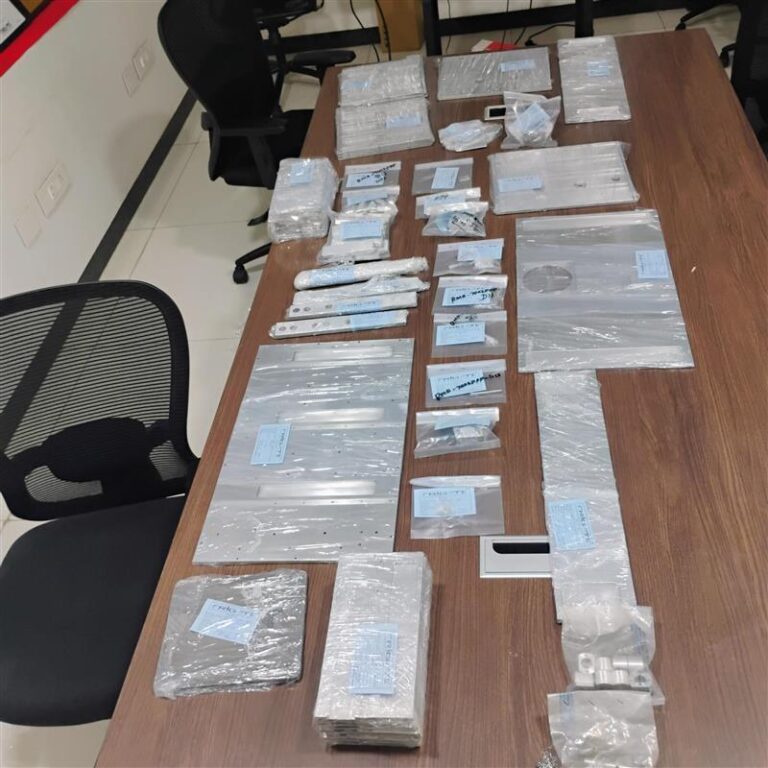

- Machined Component Showcase

CNC Machining Parts

We maintain stringent dimensional consistency through high-resolution spindle encoders, thermal drift compensation, and ultra-fine servo motor tuning. Delivering components engineered to withstand extreme mechanical stresses and fluctuating thermal environments.

Other Industries We Serve

We deliver machining support across sectors that require consistency, material reliability, and tight dimensional control.

- Solid Progress

Our Manufacturing Metrics

Frigate brings stability, control, and predictable performance to your sourcing operations through a structured multi-vendor system.

2.8X

Sourcing Cycle Speed

Frigate’s pre-qualified network shortens decision time between RFQ and PO placement.

94%

On-Time Delivery Rate

Structured planning windows and logistics-linked schedules improve project-level delivery reliability.

4X

Multi-Part Consolidation

We enable part family batching across suppliers to reduce fragmentation.

22%

Quality Rejection Rate

Multi-level quality checks and fixed inspection plans lower non-conformities.

30%

Procurement Costs

Optimized supplier negotiations and bulk order strategies reduce your overall sourcing expenses.

20%

Manual Processing Time

Automation of sourcing and supplier management significantly reduces time spent on manual tasks.

Get Clarity with Our Manufacturing Insights

- FAQ

Having Doubts? Our FAQ

Check all our Frequently Asked Questions in CNC Machining

Frigate uses real-time tool path monitoring and dynamic load compensation during machining. This maintains uniform stress distribution and avoids microfractures in critical load-bearing areas. High-speed probing checks the concentricity and web thickness in each cycle. Final inspection includes ultrasonic flaw detection to ensure structural reliability under cyclic loads.

Frigate uses vacuum clamping combined with precision surface milling to maintain flatness over wide surfaces. Thermal expansion during machining is controlled using chilled coolant and cycle time segmentation. A CMM scan verifies parallelism across multiple datum points. This ensures stable panel alignment and load resistance in outdoor installations.

Frigate uses harmonic analysis to tune spindle RPMs and feed rates to avoid chatter in thin-walled sections. Tool engagement angles are customized to distribute cutting forces evenly. Adaptive toolpaths reduce back pressure and edge deflection. All parameters are verified through dry runs and accelerometer feedback loops.

Yes, Frigate uses segmented tooling strategies and tool change synchronization to machine dissimilar materials in a single setup. RPM and torque profiles are adjusted at material transition zones. Tool coatings are selected to prevent delamination or bimetallic wear. This allows precise machining of mixed-material components used in high-performance assemblies.

Frigate machines oversized shafts using synchronized dual-head gantry systems to reduce bending and deflection. Inline laser tracking monitors Z-axis drift during tool travel. Compensatory offsets are applied in real time to maintain length and roundness tolerances. Final parts are tested on rotating inspection beds to simulate in-field shaft alignment.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany