We offer standard 6000mm × 1000mm panels and support custom sizes like 4000mm × 1200mm for modular layouts. Using Q235, A36, or stainless steel, each panel is fusion-welded to ensure consistent bonding and low deflection under load.

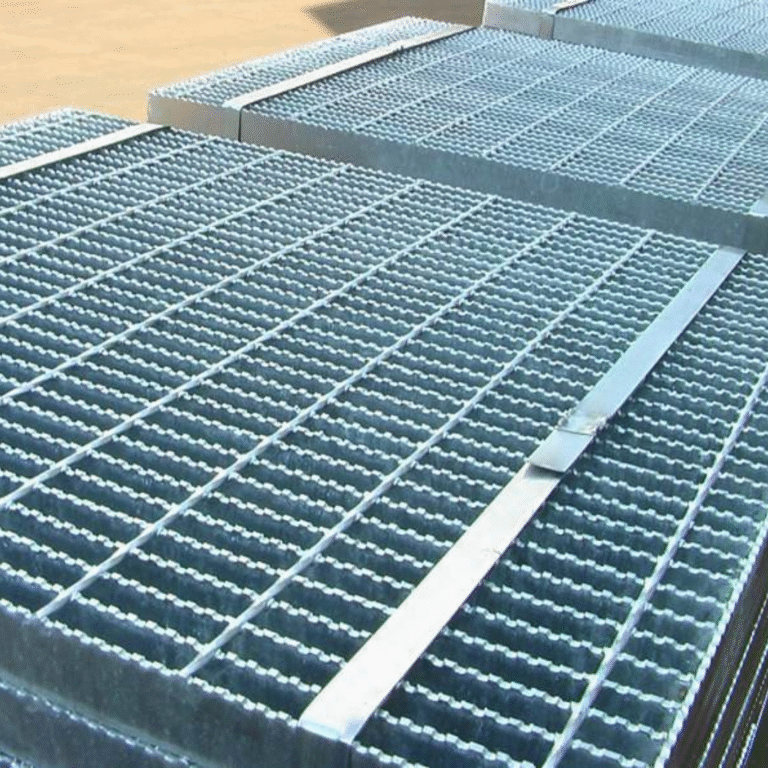

We weld each joint by electro-forging, which gives uniform crossbar lock without bending or shifting during transport. Standard bar depths range from 25mm to 50mm and are selectable by site load requirements and span design.

Panels are built using Q235 or A36 steel, with stainless options for high-humidity or food plant use. We offer hot-dip galvanizing per ISO 1461 and painted or mill finishes depending on use case or budget.

Need reliable Gratings for your next project? Get in touch with us today, and we’ll help you find exactly what you need!

Carries up to 5 Ton/m² live load with 30mm bar spacing to ensure stable access near tanks, mixers, or pumps.

Hot-dip galvanized panels resist corrosion near turbine rooms and boilers, holding firm against high ambient heat.

Custom 3000mm × 500mm units integrate with tight marine platforms while serrated edges boost slip protection.

Open area supports air and debris flow while 8mm bar thickness holds bulk hopper weights without deflection.

50mm × 50mm bar spacing meets drainage requirements while maintaining car wheel load support.

Meets AS 1657 for foot safety near servicing zones with optional banded edging and slip-resistant top surfaces.

Each grating ships with exact spacing, thickness, and edge profiles as per approved layout drawings. We match regional compliance codes like EN 1433 and AS 1657, and support ISO 9001 quality documentation.

For repeat orders, we provide batch-labeled panels with full weight, thickness, and coating data. You can also request bar layout drawings and surface test reports to support internal checks.

Check all our Frequently Asked Question

Yes, we can supply panels with varying lengths, bar depths, and spacing in one consolidated dispatch. You can combine 30mm, 40mm, and 50mm bar spacing based on usage zones. We tag and palletize each type separately to simplify onsite installation.

We share bar load tables and deflection charts specific to the depth, spacing, and thickness you choose. Each value is verified against lab results and standard span conditions. This helps you match grating to floor load zones during design review.

Yes, we use automated electro-forging which locks every crossbar at uniform pressure and temperature. Our QC team checks weld integrity with load-point testing across samples per ISO 9001 process. This ensures no panel deforms or weakens under site pressure.

Hot-dip galvanizing is the best option for long-term use and corrosion exposure. It adds upfront cost but reduces maintenance cycles by over 5 years compared to paint. For dry interiors, painted or bare finish works when budget is the key factor.

We store your grating specs, panel layouts, and finish types in our system for fast replication. You can reorder matching units even months later without new drawings. This helps avoid mismatches or redesigns during project phase two or expansion.

Submit the form below and our representative will be in touch shortly.

Our team is ready to provide the support and expertise you need.

Need reliable Gratings for your next project? Get in touch with us today, and we’ll help you find exactly what you need!

Need reliable Machining for your next project? Get in touch with us today, and we’ll help you find exactly what you need!

Need reliable wires and cables for your next project? Get in touch with us today, and we’ll help you find exactly what you need!