Telecommunication networks depend heavily on the performance and reliability of their cable infrastructure. With growing demand for bandwidth and network reach, Aerial Cables for Telecommunication Networks have become a strategic asset for carriers and service providers. Effective cable procurement decisions influence deployment speed, operational costs, and long-term scalability.

Understanding the technical nuances of ADSS (All-Dielectric Self-Supporting) cables and other aerial cables for telecommunication networks is critical for achieving optimal network resilience and efficiency. This guide explores the core technical benefits of these cable types and highlights essential procurement considerations that address typical challenges encountered in large-scale telecom projects. Frigate’s expertise is woven into each key area to demonstrate best practices and solutions.

How ADSS & Aerial Cables Are Efficient for Telecommunication Networks?

Aerial cables for telecommunication networks, especially ADSS types, play a vital role by combining electrical insulation, mechanical strength, and environmental durability. Their design supports safe deployment near high-voltage lines, reduces infrastructure demands, and ensures long-term reliability. These efficiencies help optimize network performance, lower maintenance costs, and enable future scalability in diverse installation environments.

Electrically Insulative Design for High-Voltage Corridor Compatibility

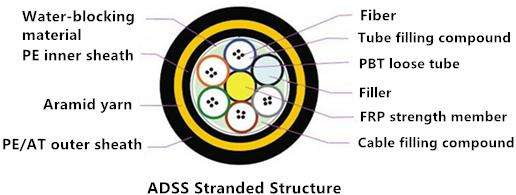

ADSS cables feature an all-dielectric construction, completely devoid of metallic components, thereby eliminating conductive pathways. This intrinsic electrical insulation prevents electromagnetic interference (EMI) and induced currents typically experienced by metallic aerial cables for telecommunication networks installed adjacent to high-voltage power lines.

These cables meet stringent dielectric strength specifications, allowing for safe deployment in energized corridors. Their robust insulation mitigates partial discharge phenomena and electrical tracking, substantially reducing the incidence of network faults and enhancing overall system reliability and operational safety.

Self-Supporting Structural Integrity for Optimized Infrastructure Utilization

The mechanical design of ADSS cables incorporates integrated tensile strength members, enabling the cable to be self-supporting over extended spans without requiring auxiliary support elements, such as messenger wires or steel strands. This capability reduces structural loading on support poles and towers, resulting in lower infrastructure capital expenditures and simplified civil works.

Long span performance facilitates route flexibility in diverse geographic and urban planning scenarios, accommodating wider pole spacing and minimizing the total number of support structures required. This contributes to faster deployment cycles and reduced maintenance complexity.

Enhanced Mechanical Robustness and Environmental Resistance

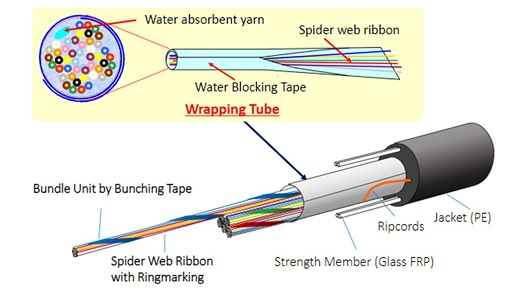

The outer sheath and strength members of aerial cables for telecommunication networks are engineered from high-performance polymers with superior mechanical and environmental properties. These materials are selected based on abrasion resistance, UV stabilization, hydrolytic stability, and coefficient of thermal expansion to withstand dynamic loading conditions such as wind-induced vibration, ice accretion, and temperature fluctuations.

Mechanical robustness ensures fiber microbending is minimized under dynamic stresses, preserving low optical attenuation and maintaining signal integrity across varying climatic and mechanical stressors.

High-Density Fiber Capacity for Future-Proof Network Scalability

Aerial cables for telecommunication networks are designed with a modular fiber architecture, including loose-tube and ribbon fiber configurations, to maximize fiber count within optimized cable diameters. This design strategy supports scalability, allowing network operators to accommodate exponential growth in bandwidth demand without necessitating additional cable installations.

Optimized fiber packing ratios, coupled with advanced fiber management techniques, facilitate efficient heat dissipation and mechanical protection, which are critical for maintaining fiber performance and durability in high-count cable assemblies.

Extended Operational Lifecycle with Reduced Maintenance Overhead

Employing advanced polymeric compounds and precision extrusion manufacturing processes results in aerial cables for telecommunication networks with operational lifespans exceeding 25 years. These materials exhibit superior resistance to environmental aging mechanisms, including UV degradation, moisture ingress, and thermal cycling.

Cable designs minimize microbending losses and tensile strain on the optical fibers through engineered strain-relief components and controlled cable geometry. This significantly lowers the frequency of fiber breaks and attenuation spikes, thereby reducing routine maintenance interventions and enabling rapid fault localization and restoration to maintain high network availability.

Things to Consider While Procuring ADSS & Aerial Cables

Effective procurement of ADSS and aerial cables for telecommunication networks demands a rigorous, multidimensional evaluation process. Decisions must integrate detailed technical criteria, infrastructure constraints, regulatory mandates, and total cost of ownership considerations. A methodical approach to procurement minimizes operational risks, ensures compliance, and aligns cable specifications with long-term strategic network goals. The following key factors serve as a framework to guide informed decision-making, optimize asset performance, and enhance the reliability and scalability of telecommunication networks.

Strategic Infrastructure Compatibility

The successful deployment of ADSS and aerial cables for telecommunication networks requires an exhaustive evaluation of physical infrastructure and environmental variables. Terrain topology, span distances, and existing support pole specifications determine mechanical design parameters, including tensile strength, modulus of elasticity, and allowable elongation limits. Underestimating these factors risks excessive cable sag, structural overloading, and accelerated mechanical fatigue, which can compromise the integrity of optical fibers and lead to premature service failures.

Frigate employs a systems engineering approach that integrates advanced mechanical modeling tools, including finite element analysis (FEA) and dynamic tension-sag simulations. These predictive models assess site-specific variables—such as wind load, ice accretion, thermal expansion, and support structure deflection—to engineer cable solutions that are precisely tailored to the physical route conditions. This rigorous methodology minimizes installation risk, optimizes cable lifespan, and enhances overall network resilience.

Balancing Capital Investment with Total Cost of Ownership (TCO)

A holistic procurement strategy extends beyond initial acquisition costs by considering the full lifecycle financial impact of aerial cable solutions. While lower upfront expenditures may appear attractive, inferior cable designs typically incur higher maintenance costs, increased fault rates, and higher operational expenditures, ultimately undermining network uptime and service-level agreements.

Frigate’s procurement philosophy prioritizes durability and operational efficiency through material science innovation and precision manufacturing. Selection of advanced polymeric sheaths with enhanced environmental resistance, coupled with robust strength member engineering, reduces maintenance frequency and extends mean time between failures (MTBF). This approach yields a favorable Total Cost of Ownership (TCO) profile by curtailing unplanned outages, reducing field intervention costs, and safeguarding revenue streams derived from consistent network availability.

Electrical Field and Tracking Resistance

ADSS cables installed within energized high-voltage corridors face complex dielectric stresses, including corona discharge and surface tracking phenomena, which jeopardize sheath integrity and fiber performance. Materials used in cable sheaths must exhibit exceptional tracking resistance, dielectric strength, and thermal stability to withstand prolonged exposure to electrical fields exceeding several kilovolts per meter.

Frigate utilizes proprietary compound formulations engineered for elevated electrical resistivity and minimal surface degradation under high-voltage stress. Comprehensive accelerated aging and electrical endurance testing—compliant with IEC 60587 and IEEE 1138 standards—ensures cables maintain their structural and electrical integrity throughout their operational life, thereby reducing network vulnerability and the need for costly maintenance interventions.

Compliance with International and Regulatory Standards

Compliance with prevailing international standards such as IEC 60794-1-2, IEEE 1138, ITU-T G.652/G.655, and relevant national codes is non-negotiable for regulatory acceptance, interoperability, and long-term operational assurance. Adhering to these standards assures mechanical, optical, and environmental performance under standardized test conditions, facilitating seamless integration with existing network elements.

Frigate’s stringent quality assurance protocols encompass detailed conformity assessments, third-party certifications, and continuous process audits. Delivering cables certified to global and country-specific standards ensures expedited approval processes and mitigates risks related to regulatory non-compliance, enabling accelerated project timelines and investment protection.

Tailored Engineering for Project-Specific Challenges

Standardized cable designs often fail to meet the nuanced demands of complex deployments. Factors such as atypical span lengths, extreme climate zones, corrosive environments, or stringent bend radius limitations necessitate custom engineering solutions. Advanced modeling—incorporating thermal stress analysis, mechanical load forecasting, and material degradation prediction—guides cable architecture modifications.

Frigate’s engineering team employs multi-physics simulation platforms to optimize cable geometry, strength member composition, and sheath formulation. These tailored designs accommodate site-specific loading scenarios, mitigate microbending-induced attenuation, and ensure long-term fiber performance even in the most demanding environmental conditions, preserving signal fidelity and operational stability.

Adaptability to Hybrid Deployment Scenarios

Telecommunication networks are increasingly incorporating hybrid deployment zones that blend dense urban infrastructure with remote rural expanses. Such diversity introduces variable mechanical loads, environmental stresses, and installation constraints.

Frigate delivers modular cable solutions with scalable mechanical reinforcement and adaptive sheath technologies engineered for heterogeneous deployment profiles. This flexibility ensures consistent performance and mechanical reliability irrespective of urban congestion, limited pole infrastructure, or exposure to extreme weather patterns, thereby simplifying inventory management and enhancing network scalability.

Supply Chain Optimization and Risk Mitigation for Timely Deployment

Supply chain disruptions pose significant risks to project timelines, capital allocation, and stakeholder commitments. Factors including raw material scarcity, geopolitical instability, and transportation bottlenecks necessitate strategic supply chain planning.

Frigate maintains a diversified manufacturing footprint and regional distribution centers to mitigate lead time volatility. Integrated demand forecasting, real-time inventory tracking, and agile logistics coordination ensure alignment of cable deliveries with project milestones, reducing downtime risk and preserving capital expenditure schedules critical to large-scale telecommunication rollouts.

Integration of Optical Monitoring Capabilities for Network Performance Management

Embedding diagnostic fibers compatible with OTDR and distributed sensing technologies within aerial cables for telecommunication networks enables real-time network condition assessment and proactive fault localization. Such capabilities are integral to modern intelligent network management systems, reducing mean time to repair (MTTR) and enhancing service reliability.

Frigate’s cable designs incorporate dedicated monitoring fiber elements with optimized routing and mechanical protection, facilitating seamless integration of optical performance monitoring tools without compromising cable robustness or optical transmission quality.

Rigorous Quality Assurance

Mechanical, environmental, and electrical performance verification underpins the reliable operation of cables. Testing regimens encompass tensile strength assessments, cyclic bending, thermal cycling, UV exposure, moisture ingress resistance, and electrical withstand evaluations.

Frigate’s state-of-the-art testing facilities replicate extreme field conditions to validate the robustness of cable designs and ensure manufacturing consistency. Continuous process monitoring and batch-level certification reinforce quality assurance, delivering cables that meet stringent client specifications and reduce field failure incidence.

Conclusion

The successful deployment of Aerial Cables for Telecommunication Networks hinges on an integrated approach that combines electrical safety, mechanical resilience, regulatory compliance, and lifecycle cost management. Precise engineering and supply chain strategies ensure infrastructure scalability and operational reliability.

Frigate delivers comprehensive solutions addressing these technical challenges through custom cable design, stringent quality control, and robust logistics. Selecting aerial cables for telecommunication networks aligned with project demands safeguards network performance today and supports expansion for tomorrow’s communication needs.

Engage with Frigate to access expert consultation and procure aerial cable solutions engineered for excellence and longevity.