- Energy Control

Transformers for LED Lighting Systems

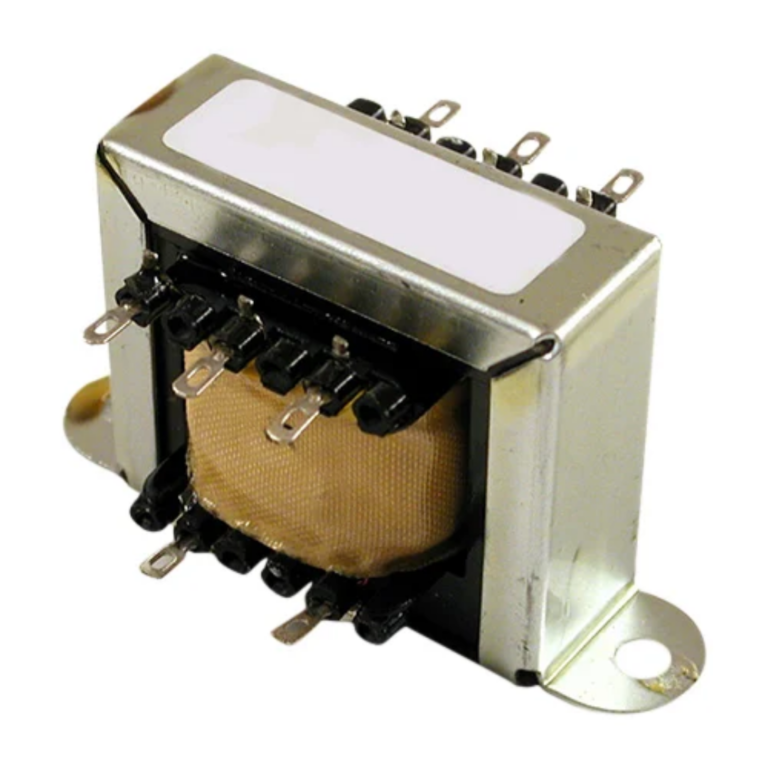

Frigate’s transformers for LED lighting ensure stable voltage delivery, thermal efficiency, and EMI compliance across architectural and industrial lighting platforms.

- Timely Dispatch

- Cost Efficiency

- Pre-Production Samples

- Stable Output Across Voltage Variations

Built for wide input conditions, these transformers support consistent voltage delivery using optimized core construction and controlled magnetic flux distribution.

- Continuous Performance with Thermal Control

Low-loss core materials and Class B/F insulation allow operation in enclosed lighting housings without overheating, even during extended usage.

- Space-Efficient with Safety Isolation

Compact toroidal and laminated cores fit restricted lighting spaces while maintaining electrical separation as per IEC 61558 safety distance rules.

- Global Trust

Our Clients

Preferred by OEMs and system designers for transformer sourcing

- Engineered Range

Our Products

Browse our transformer lineup built to support diverse voltage, insulation, and mounting needs across industries.

- Products Delivered

Feedback from Transformer Clients

Hear how procurement teams and engineering leads rate our transformer reliability, customization depth, and production consistency.

“Been using their dry-type units for the last 6 months. Build quality is solid. No overheating, no complaints.”

“Very smooth sourcing. Cords work fine. Packaging was neat also!”

“High frequency noise dropped significantly. We tested many suppliers but this part was very stable. Frigate team answered all specs questions quickly.”

“The units were delivered well-packed. Slight delay on customs but Frigate handled all communication quickly. Output stability is very reliable. Good value for money.”

“ Fire rating passed inspection, no trouble. Cables are flexible enough for tight runs. Cheers to Frigate.”

“We sourced this for an automotive application... Fitment exact. Thermal performance very clean. Price also reasonable. No issue so far! ”

“Cable is very tough... no crack during installation, even in outdoor condition. Shipment take 3 weeks, but product was good. We Source again sure.”

“ Frigate sent us samples Fast. The lamination is smooth, no burrs. Our assembly team had zero fitting issues.”

“ Delivery time was okay. The plastic molding finish on the plug could improve. But it works well. Good for bulk orders.”

“ We installed the busbars into our LV switchboards. Stable output readings and connection layout was compact. Better than our last supplier.”

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

- Lighting Power

Transformer Use in LED Lighting Systems

LED lighting transformers are critical for powering drivers, dimmers, and converters that require consistent voltage and insulation. We build each unit to support system efficiency, EMI control, and power factor requirements in indoor and outdoor lighting installations.

Architectural Lighting Units

Delivers regulated voltage with minimal ripple, supporting LED drivers in commercial and decorative lighting with high lumen stability.

Industrial Lighting Fixtures

Supports thermal and electrical durability in harsh environments, including high-bay and floodlight installations where constant output is essential.

- Design Flexibility

Custom Transformer Integration for LED Systems

Frigate supplies transformers customized for mechanical formats and electrical interfaces, minimizing integration time for LED driver and lighting OEMs.

Flexible Mounting & Termination Options

We provide vertical or horizontal mount designs, wire-lead or terminal-block connections, and footprint adjustments to fit enclosure needs.

Supports Driver Circuit Integration

Our transformers work within PFC pre-regulation, isolated driver stages, or EMI filter paths in both constant current and constant voltage applications.

Full-Spectrum Transformer Solutions

Engineered for high-reliability environments, our LED Lighting Systems transformers deliver precise voltage regulation, low leakage current, and superior EMI suppression.

- Verified for Performance

Power Components That Meet Testing Standards

Frigate produces transformers for LED lighting systems that undergo rigorous quality testing to confirm safety, durability, and consistent electrical performance. Each unit is tested to meet application-specific demands for efficiency, heat tolerance, and long operational life.

- Our Blogs

Insights from Transformer Manufacturing Experts

Read technical articles on transformer integration, compliance standards and sourcing strategies across industry-specific use cases.

Frigate selects low-loss core materials to limit heat generation in compact lighting housings. Class B or F insulation ensures safety under sustained thermal loading. Windings are configured to minimize internal resistance and reduce temperature rise. Each design undergoes thermal modeling and load testing under typical enclosure conditions.

Frigate integrates shielding layers and interwinding insulation to control EMI in low-voltage lighting transformers. Toroidal cores with balanced winding layouts reduce magnetic field leakage. Design geometry minimizes coupling capacitance and noise propagation. Every unit is validated for conducted and radiated emissions under lighting-specific EMC parameters.

Frigate supports vertical and horizontal mounting formats for driver circuit integration. Electrical specifications such as regulation tolerance, winding topology, and saturation current are tailored to application needs. Housing constraints are addressed through custom bobbin shapes and terminal types. Each configuration is built for compatibility with dimming and constant current stages.

Frigate uses precision core materials and tight winding tolerances to reduce voltage drop during load shifts. The magnetic design is tuned to avoid flux imbalance and minimize output ripple. Transformers are tested under fluctuating loads to confirm voltage consistency. This supports stable LED brightness across dynamic operating conditions.

Each transformer is tested for insulation resistance, dielectric withstand, and leakage current based on IEC 61558 and UL 5085 protocols. Frigate applies hi-pot and surge testing calibrated to safety thresholds. Test results are recorded for batch-level traceability. Manufacturing processes follow documented quality systems to support third-party certification audits.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany