Although custom sheet metal fabrication is boring, it’s not flat at all. For ages, the craft of sheet metal fabrication has been revered. Ancient societies employed metalworking skills to make tools, armor, and weapons.

Today’s sheet metal fabricators are comparable to contemporary blacksmiths. They take raw resources and turn them into useful goods that people use daily.

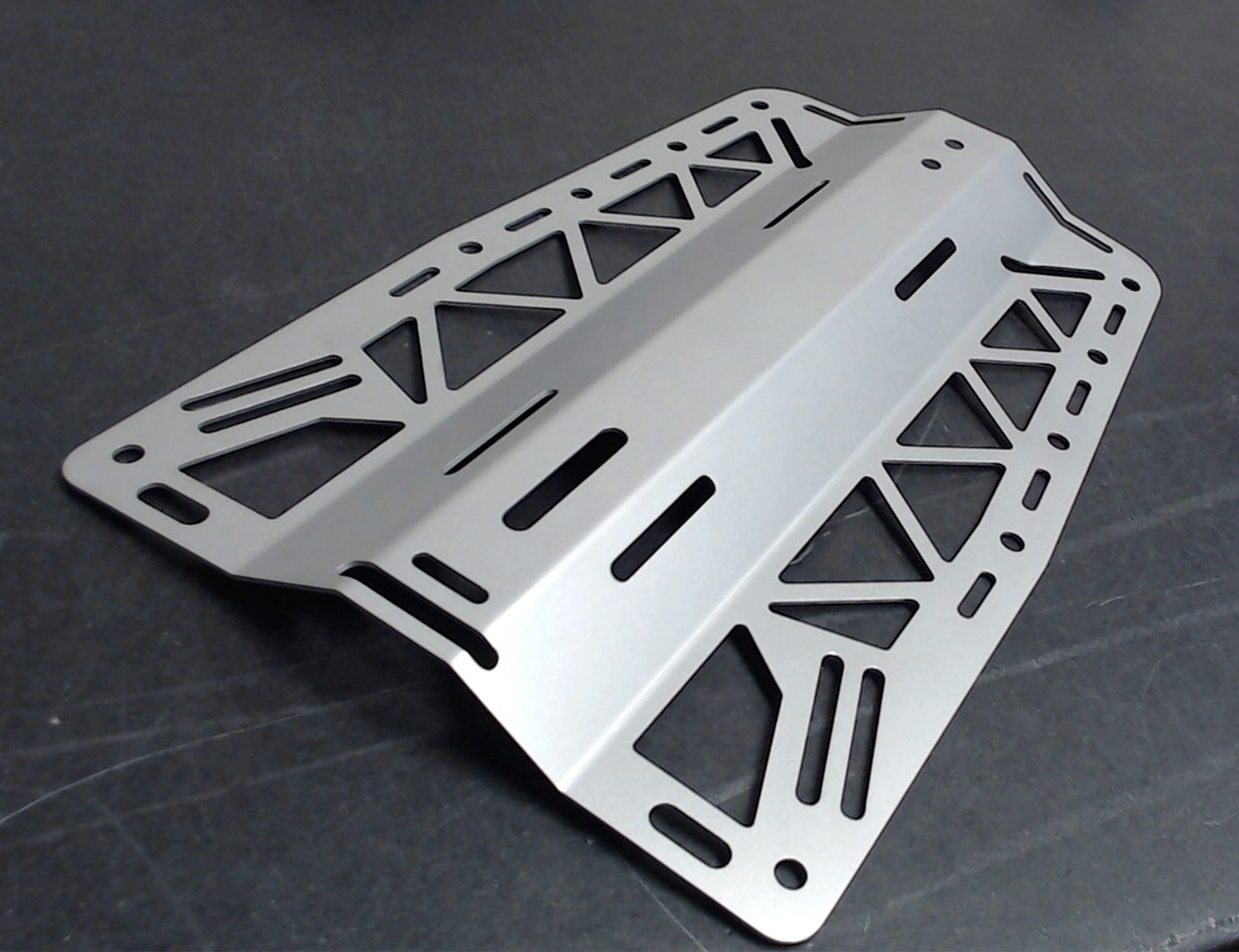

A thin, flat plate of metal is called sheet metal. It is commonly composed of steel, aluminum, brass, or copper and comes in various diameters and thicknesses. Custom sheet metal fabrication is widely used, adaptable, and essential to many different sectors.

What is custom sheet metal fabrication?

Sheet metal fabrication is cutting, folding, bending, and assembling flat metal sheets into the appropriate parts and products.

Various metal materials, such as brass, copper, zinc, stainless steel, aluminum, and steel, can be used for many different sheet metal fabrication procedures. The gauges for sheet metal thickness range from approximately 0.006 to 0.25 inches. While narrower gauges are more malleable, thicker gauges are better suited for heavy-duty applications.

Professional metal fabricators employ various methods to produce sheet metal parts following a comprehensive design phase that establishes product standards. The particular requirements of the finished product will determine which combination of techniques is used. Cutting, shaping, connecting, and finishing are the fundamental steps.

What are the advantages of custom sheet metal fabrication?

Fabricating sheet metal requires a number of methods and procedures. As a result, depending on the process selected, the advantages and restrictions change. The benefits of manufacturing sheet metal parts are highlighted in this section.

Efficiency and Accuracy

Recent advancements in sheet metal technologies have made it possible to produce goods more quickly and effectively. Prototypes can be produced more quickly and precisely than production runs. For example, laser beams can penetrate steel that is 1 mm thick at a pace of 18 m/min. Depending on your project, you can additionally optimize the nozzle’s power and speed.

A Wide Range of Techniques and Materials

To make an item made of sheet metal come to life, there are multiple methods utilised. Cutting, bending, punching, stamping, rolling, and other methods are among them. Every procedure has a unique goal for producing components in various sizes and forms. Every time a component needs more finishing, there are many of possibilities for surface finishing.

In a similar vein, there are numerous options available for sheet metal, such as copper, steel, aluminium, stainless steel, and other speciality metals. The final use of your product will determine the material you use.

Manufacture Lightweight Parts

For lightweight items, sheet metal fabrication is a great manufacturing method. Advanced materials and processes are used in sheet metal manufacturing by industries including aerospace and automotive. This manufacturing process contributes to the production of efficient parts that increase vehicle and aircraft fuel efficiency. The success of architecture, machine tools, and general engineering also depends on lightweight constructions made possible by sheet metal production.

Applications of custom steel metal fabrication

Many different businesses use custom sheet metal production, and each has its own special needs and difficulties. Let’s examine a few of these sectors and the particular instances of custom sheet metal items utilized in them:

Architecture and Construction

Custom sheet metal is essential to the production of iconic structures and useful building elements in the architectural and construction industries. Stainless steel is a common material for architectural applications because of its strength and aesthetic appeal. It is employed in the fabrication of handrails, decorative panels, facade cladding, and other structural components.

Electronics and Telecommunications

Custom sheet metal fabrication is used by the electronics and telecommunications industries to create enclosures, racks, chassis, and other parts for communication systems and electronic devices. Sensitive electronic equipment can operate smoothly because of the physical protection and electromagnetic shielding that these manufactured components offer.

Automotive and Aerospace

In the automotive and aerospace sectors, custom sheet metal fabrication is used to create various components, including engine parts, aircraft interiors, body panels, and structural supports. In these industries, where performance optimization and weight reduction are critical, the capacity to build robust, lightweight metal components through custom fabrication techniques is essential.

Food and Beverage

Custom sheet metal fabrication is essential in the food and beverage industry due to the need for hygienic, durable equipment, often made from stainless steel for its corrosion resistance and easy cleaning. This approach benefits various sectors, offering tailored designs and materials to optimize performance in applications like HVAC systems, architectural elements, and food production equipment.

Conclusion

It is a wise decision to think about custom sheet metal fabrication for manufacturing applications. In this article, we go over sheet metal fabrication to a great extent, including all the information you need to get started on your project.

We at Frigate are aware of the many opportunities and difficulties associated with industrial manufacturing. Please contact us for further details right now.