- Mechanical Stability

Electrical Equipments for Railway

Frigate’s vibration-endurance wiring, built with Class 6 fine-stranded conductors and cross-linked elastomer insulation, ensures long-term mechanical stability under IEC 61373 Category 1B conditions in underfloor and bogie-mounted railway systems.

- Timely Dispatch

- Cost Efficiency

- Pre-Production Samples

- Impedance Stability and EMI Shielding

Dual-shielded construction with controlled dielectric geometry ensures signal integrity and suppresses EMI across high-frequency railway communication networks.

- Flame-Rated Halogen-Free Insulation

LSZH materials limit smoke, flame spread, and corrosive gases, meeting EN 45545-2 HL3 and IEC 60332-3-24 fire safety standards.

- High-Temperature Power Endurance

Cross-linked elastomer insulation enables reliable power delivery under +150°C surges, maintaining dielectric performance in propulsion and auxiliary systems.

- Industrial Power

Future-Ready Electrical Solutions

Partner with Frigate to implement advanced electrical technologies enabling high-voltage endurance system reliability and future-ready industrial power architectures.

- Broad Product Range

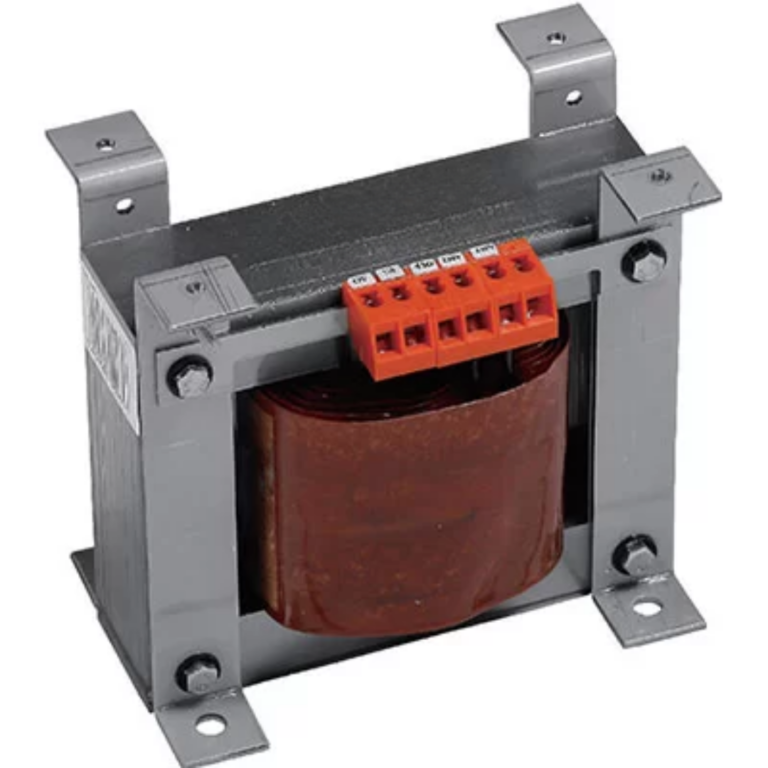

Electrical Components We Manufacture

From Cables & Wires to Transformers, Our Electrical Products power your projects across industries. Browse below to find what suits your needs.

- Shared Experience

In Their Words

Endorsed by industry decision makers who value our streamlined procurement and efficient execution.

“Been using their dry-type units for the last 6 months. Build quality is solid. No overheating, no complaints.”

“Very smooth sourcing. Cords work fine. Packaging was neat also!”

“High frequency noise dropped significantly. We tested many suppliers but this part was very stable. Frigate team answered all specs questions quickly.”

“The units were delivered well-packed. Slight delay on customs but Frigate handled all communication quickly. Output stability is very reliable. Good value for money.”

“ Fire rating passed inspection, no trouble. Cables are flexible enough for tight runs. Cheers to Frigate.”

“We sourced this for an automotive application... Fitment exact. Thermal performance very clean. Price also reasonable. No issue so far! ”

“Cable is very tough... no crack during installation, even in outdoor condition. Shipment take 3 weeks, but product was good. We Source again sure.”

“ Frigate sent us samples Fast. The lamination is smooth, no burrs. Our assembly team had zero fitting issues.”

“ Delivery time was okay. The plastic molding finish on the plug could improve. But it works well. Good for bulk orders.”

“ We installed the busbars into our LV switchboards. Stable output readings and connection layout was compact. Better than our last supplier.”

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

- Reliable Rail Performance

Ensuring Signal and Power Integrity in Rail

Railway electrical systems are engineered for compliance with IEC, EN, and UIC standards under high vibration, thermal load, and EMI exposure. These systems support traction, signaling, and auxiliary functions while maintaining operational stability across diverse rolling stock and fixed infrastructure environments.

Rolling Stock Electrical Integration

Supports propulsion, control, and auxiliary systems using heat-resistant, vibration-tolerant wiring with Class 6 conductors and EN 45545-2 compliant insulation.

Signaling and Trackside Equipment

Enables safe interlocking, power distribution, and communication using shielded, moisture-resistant cables with stable impedance and high EMI immunity.

- Modular Integration

Modular Harness Integration

Pre-engineered harness systems with rail-approved terminations and EN 50343 compliance ensure repeatable routing and reduced variability across modular rolling stock platforms.

Environmental Sealing and Contact Reliability

Ingress-resistant designs using IP66/IP67-rated housings and corrosion-resistant alloys maintain electrical performance under high salinity, humidity, and particulate exposure.

System-Level Compatibility and Standards

Electrical components meet IEC, EN, UIC, and RDSO standards, ensuring dielectric, mechanical, and electromagnetic compatibility across new and legacy rail systems.

Precision Electrical Systems for Every Industry

Built for demanding sectors, our electric products offer accurate voltage regulation, thermal stability, and EMI shielding—customized for Railways applications.

- Rail Power

Next-Generation Testing for Traction Transformers

Railway transformers must sustain continuous load variations, mechanical vibrations, and environmental stress.

Analysis

Testing

- Energy Reliability

Electrical Market Insights

Explore how advanced insulation and dielectric technologies are redefining reliability in modern industrial power systems.

Frigate uses pre-assembled harnesses with IP67-rated connectors designed for dynamic flex zones between coaches. Each connector is tested for mechanical locking, vibration endurance, and sealing under EN 61373 and IEC 60529. Cable assemblies include anti-wicking barriers to prevent moisture migration. This ensures stable electrical continuity despite constant movement and mechanical shock.

Frigate designs cables with dual shielding: an aluminum-polyester tape and a high-coverage copper braid. Shield terminations are 360° bonded to prevent EMI leakage at joints. Impedance is controlled through consistent insulation geometry, especially for Ethernet and CAN lines. These cables are tested for EMC behavior under EN 50121-3-2.

Frigate uses halogen-free flame-retardant compounds that comply with EN 45545-2 (HL3 for R22 and R23). Cables are tested for smoke density, acid gas release, and flame propagation under IEC 60332 and EN 61034. Materials maintain insulation resistance after flame exposure. This protects both passengers and equipment during thermal events.

Frigate cables are rated for 300V, 600V, or 1000V depending on the network design and insulation thickness. Voltage surge and fluctuation tolerance is tested per IEC 60502-1. Insulation and conductor spacing are calculated to prevent dielectric breakdown under transient overload. This enables safe operation across traction, auxiliary, and control systems.

Frigate uses terminal enclosures made from stainless steel 316 or nickel-plated brass to resist salt fog and dust. All contact surfaces are treated for low resistance and corrosion resistance using tin or silver plating. Enclosures are IP66/IP67 rated and tested per ISO 9227 salt spray conditions. These prevent oxidation and electrical degradation over time.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany