- Precision Power

Transformers for Medical Devices

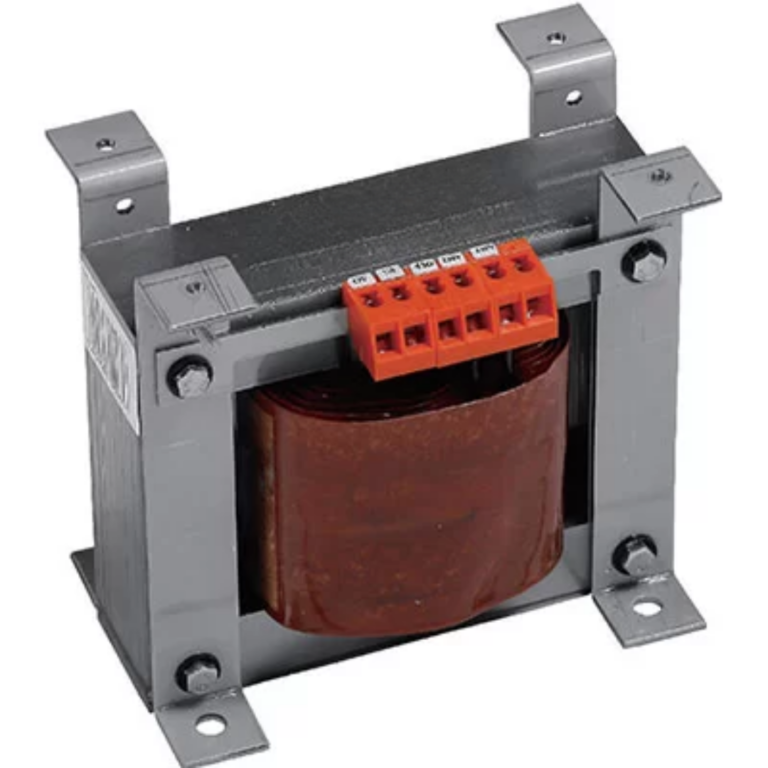

Frigate’s medical transformers ensure fail-safe performance with ultra-low leakage, high isolation, and thermal reliability for critical healthcare systems.

- Timely Dispatch

- Cost Efficiency

- Pre-Production Samples

- Stable Voltage Under Load

Designed for fluctuating loads, these transformers maintain voltage precision using low leakage inductance and optimized magnetic core coupling.

- Thermal Stability for 24/7 Use

Constructed with low-loss cores and Class F/H insulation to ensure safe, reliable thermal performance under continuous full-load operation.

- Compact Design with Isolation

High-density toroidal or planar cores deliver space efficiency while preserving creepage, clearance, and IEC 60601-1-compliant electrical separation.

- Global Trust

Our Clients

Preferred by OEMs and system designers for transformer sourcing

- Engineered Range

Our Products

Browse our transformer lineup built to support diverse voltage, insulation, and mounting needs across industries.

- Products Delivered

Feedback from Transformer Clients

Hear how procurement teams and engineering leads rate our transformer reliability, customization depth, and production consistency.

“Been using their dry-type units for the last 6 months. Build quality is solid. No overheating, no complaints.”

“Very smooth sourcing. Cords work fine. Packaging was neat also!”

“High frequency noise dropped significantly. We tested many suppliers but this part was very stable. Frigate team answered all specs questions quickly.”

“The units were delivered well-packed. Slight delay on customs but Frigate handled all communication quickly. Output stability is very reliable. Good value for money.”

“ Fire rating passed inspection, no trouble. Cables are flexible enough for tight runs. Cheers to Frigate.”

“We sourced this for an automotive application... Fitment exact. Thermal performance very clean. Price also reasonable. No issue so far! ”

“Cable is very tough... no crack during installation, even in outdoor condition. Shipment take 3 weeks, but product was good. We Source again sure.”

“ Frigate sent us samples Fast. The lamination is smooth, no burrs. Our assembly team had zero fitting issues.”

“ Delivery time was okay. The plastic molding finish on the plug could improve. But it works well. Good for bulk orders.”

“ We installed the busbars into our LV switchboards. Stable output readings and connection layout was compact. Better than our last supplier.”

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

- Medical Power

Transformer Integration in Medical Systems

Medical transformers are integral to systems requiring precise voltage control, electrical isolation, and EMC performance. We design our solutions to meet IEC 60601-1 standards, ensuring reliable operation in patient-critical environments.

Diagnostic Imaging Systems

Provides regulated power with minimal EMI, supporting high-frequency analog signal integrity and resolution in precision imaging subsystems.

Support & Monitoring Units

Ensures ultra-low leakage current and reinforced insulation, supporting BF/CF classification requirements in continuous-use, patient-contact medical equipment.

- Design Flexibility

Custom System-Level Transformer Integration

Frigate offers transformer solutions precisely tailored to your system’s mechanical and electrical integration needs, reducing design complexity and compliance risk.

Flexible Mechanical Configurations

We provide customizable mounting options, pin layouts, and termination styles to align with unique mechanical constraints in compact medical enclosures.

Designed for System Integration

Our transformers support seamless integration into SMPS circuits, analog isolation paths, or backup modules in both diagnostic and therapeutic platforms.

Full-Spectrum Transformer Solutions

Engineered for high-reliability environments, our Medical Devices transformers deliver precise voltage regulation, low leakage current, and superior EMI suppression.

- Healthcare Safety

Advanced Quality Assurance for Medical Device Transformers

Frigate ensures transformers for medical devices meet the highest standards of precision, reliability, and safety. Each unit undergoes rigorous evaluation to guarantee consistent performance in sensitive healthcare applications.

- Our Blogs

Insights from Transformer Manufacturing Experts

Read technical articles on transformer integration, compliance standards and sourcing strategies across industry-specific use cases.

Frigate engineers transformers with reinforced insulation and double MOPP (Means of Patient Protection) to meet Class CF standards. Leakage current is strictly controlled through optimized winding layout and shielding techniques. Design meets high dielectric strength and isolation distances. Each unit is tested to verify compliance with IEC 60601-1 for patient safety.

Frigate uses low-loss core materials, such as M6 or amorphous alloys, to reduce internal heating. High-temperature-rated insulation (Class F or H) prevents thermal breakdown. Thermal paths are optimized using potting compounds and open-frame ventilation. All designs are validated using thermal simulation and real-time temperature rise testing.

Frigate designs transformers with split-bobbin windings and embedded electrostatic shields to suppress conducted and radiated EMI. Core materials and winding orientation are selected to minimize magnetic field leakage. These techniques ensure compatibility with IEC 60601-1-2 EMC requirements. Every unit is validated under simulated interference environments.

Frigate offers custom mounting brackets, connector styles, and winding configurations to meet tight mechanical constraints. Electrical parameters such as turns ratio, regulation tolerance, and insulation class are configurable. Designs are optimized for space without compromising creepage and clearance. This enables direct integration into portable or embedded systems.

Each medical transformer is 100% tested for dielectric withstand, leakage current, and insulation resistance. Frigate uses automated hi-pot testing equipment calibrated to international safety standards. All results are documented for traceability and regulatory audits. Production follows ISO-compliant quality management systems suitable for medical device integration.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany