- EMC Control

Electrical Equipment

for Automotive

Frigate’s multi-shielded automotive cables with controlled impedance and precision twist ratios ensure robust EMC performance by minimizing crosstalk and emissions in high-density ADAS and ECU networks.

- Timely Dispatch

- Cost Efficiency

- Pre-Production Samples

- High-Temp Thermal Stability

Cross-linked ETFE and PEEK insulations maintain dielectric strength up to 200°C, ensuring performance under extreme engine and inverter temperatures.

- Lightweight Cable Design

Finely stranded copper and CCA conductors with thin-wall fluoropolymer jackets reduce harness mass while preserving ampacity and thermal reliability.

- Vibration-Resistant Assemblies

Strain-relieved terminations, braided sheathing, and elastomeric overmolding prevent fatigue, fretting, and disconnection under ISO 16750-3 vibration conditions.

- Industrial Power

Future-Ready Electrical Solutions

Partner with Frigate to implement advanced electrical technologies enabling high-voltage endurance system reliability and future-ready industrial power architectures.

- Broad Product Range

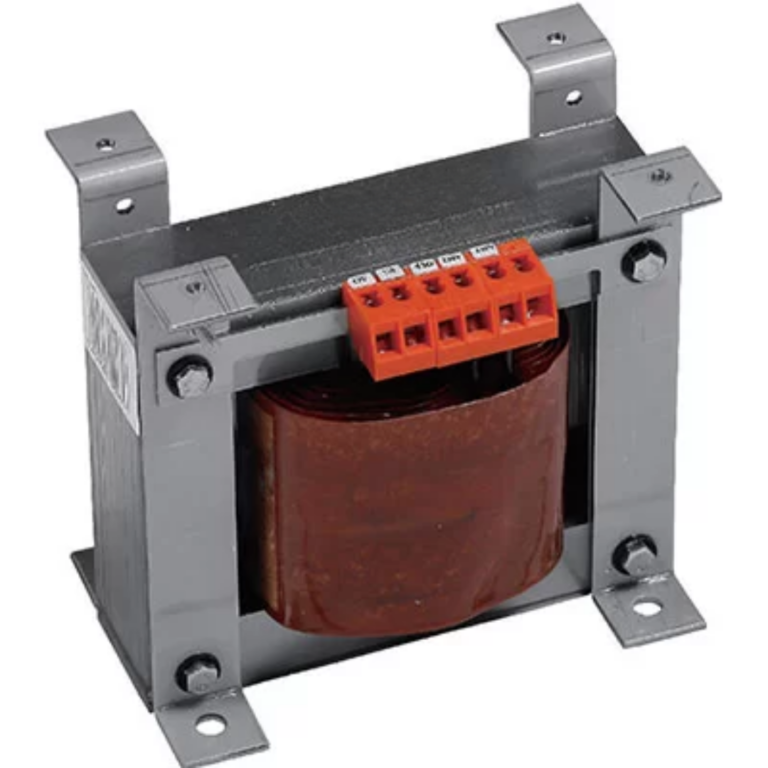

Electrical Components We Manufacture

From Cables & Wires to Transformers, Our Electrical Products power your projects across industries. Browse below to find what suits your needs.

- Shared Experience

In Their Words

Endorsed by industry decision makers who value our streamlined procurement and efficient execution.

“Been using their dry-type units for the last 6 months. Build quality is solid. No overheating, no complaints.”

“Very smooth sourcing. Cords work fine. Packaging was neat also!”

“High frequency noise dropped significantly. We tested many suppliers but this part was very stable. Frigate team answered all specs questions quickly.”

“The units were delivered well-packed. Slight delay on customs but Frigate handled all communication quickly. Output stability is very reliable. Good value for money.”

“ Fire rating passed inspection, no trouble. Cables are flexible enough for tight runs. Cheers to Frigate.”

“We sourced this for an automotive application... Fitment exact. Thermal performance very clean. Price also reasonable. No issue so far! ”

“Cable is very tough... no crack during installation, even in outdoor condition. Shipment take 3 weeks, but product was good. We Source again sure.”

“ Frigate sent us samples Fast. The lamination is smooth, no burrs. Our assembly team had zero fitting issues.”

“ Delivery time was okay. The plastic molding finish on the plug could improve. But it works well. Good for bulk orders.”

“ We installed the busbars into our LV switchboards. Stable output readings and connection layout was compact. Better than our last supplier.”

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

- Electrical Domains

Core Electrical Interfaces in Modern Automotive Engineering

Electrical components in the automotive sector are designed to meet stringent mechanical, thermal, and electromagnetic requirements across complex vehicle subsystems. Their performance directly influences vehicle safety, reliability, and functionality under varying load and environmental conditions.

High-Voltage Electric Drivetrain Integration

Used for battery-to-inverter and inverter-to-motor connections, supporting up to 800V with low partial discharge and EMI suppression characteristics.

Advanced Driver Assistance Systems

Facilitates low-latency, high-bandwidth data transmission in sensor fusion networks using shielded twisted pairs with controlled impedance and minimal crosstalk.

- Thermal Shielding

High-Voltage Isolation

Triple-extruded HV cables with XLPE and semi-conductive layers withstand >800 VDC and maintain partial discharge levels below 5 pC per IEC 60270. Shielding effectiveness exceeds 90 dB from 1–30 MHz to suppress EMI in inverter circuits.

Fluid and Chemical Resistance

Jackets made from PVDF, FEP, and PA12 provide robust resistance to oils, coolants, fuels, and salt spray. Chemical stability is validated through ISO 6722-1 and LV112, maintaining tensile strength and dielectric integrity under prolonged exposure to corrosive environments.

Harness Modularity and Diagnostics

Pre-engineered harnesses include smart routing paths, diagnostic-capable terminals, and LIN-based junctions for modular assembly and maintenance. DFA-compliant design enables robotic installation, connector keying, and predictive maintenance support across ICE and BEV systems.

Precision Electrical Systems for Every Industry

Built for demanding sectors, our electric products offer accurate voltage regulation, thermal stability, and EMI shielding—customized for automotive applications.

- Power Precision

Automotive Transformers Engineered for Extreme Road Conditions

Frigate develops automotive transformers engineered for uncompromising voltage accuracy, minimal electrical noise, and thermal resilience under sustained high-load and fluctuating driving conditions.

- Energy Reliability

Electrical Market Insights

Explore how advanced insulation and dielectric technologies are redefining reliability in modern industrial power systems.

Frigate validates connectors using ISO 16750-3 thermal/vibration cycles combined with USCAR-2 performance testing. Each connector is tested for retention force, contact resistance, and fretting wear under temperature swings and multi-axis vibration. Overmolded strain reliefs and anti-backout locks are used in critical zones. These designs ensure stable electrical contact over the entire vehicle lifecycle.

Frigate uses braid-over-foil (BOF) and foil-over-braid (FOB) shielding combinations, optimized by frequency domain analysis. These designs achieve >90 dB attenuation across 1–30 MHz, suitable for inverter switching and CAN FD signals. Shield terminations include 360° bonded terminations to ensure low-impedance grounding. This minimizes radiated emissions and ensures EMC compliance per CISPR 25 Class 5.

Frigate uses cables with reduced bend radius, thin-wall insulation, and high-flexibility Class 6 conductors for tight spaces. Routing channels are pre-designed in CAD models with minimum clearance tolerances validated through digital mock-ups. Cable routing includes heat shielding and abrasion protection layers for thermal and mechanical protection. Pre-terminated assemblies reduce on-site handling and connector misalignment risks.

Frigate applies triple-extrusion with XLPE and semi-conductive shielding to balance field strength across insulation layers. All HV cables are tested to IEC 60270 to confirm partial discharge stays below 5 pC. Cable ends are terminated with shield breakouts that eliminate corona-prone air gaps. Geometric optimization of conductor diameter and insulation wall thickness is also applied.

Frigate selects jackets like PA12, FEP, and PVDF based on ISO 6722-1 chemical soak tests. Cables are immersed in transmission oil, brake fluid, and coolants at elevated temperatures and monitored for physical degradation. Post-test insulation resistance, elongation, and dielectric strength are re-verified. This ensures material stability across long-term exposure to real vehicle environments.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany