CNC Machining Services

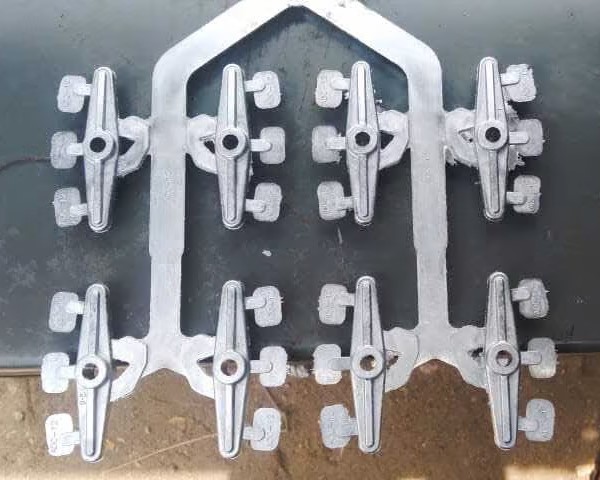

We rely on CNC machining to achieve the tight tolerances necessary for your projects. This advanced computer-assisted technology has transformed manufacturing, empowering human workers by utilizing pre-programmed software to operate machinery with unparalleled precision. Discover how CNC machining can automate the production of precision parts by contacting us at Frigate today.

What We Do

Our CNC Machining Offerings

Frigate is your expert partner in metalworking and CNC machining. Since our inception, we’ve been committed to delivering outstanding quality and customer-focused engineering solutions.

Get Your Quote Now

- Instant Quotation

- On-Time Delivery

- Affordable Cost

Advanced expertise with exceptional delivery

Beyond CNC Machining - Expertise You Can Trust

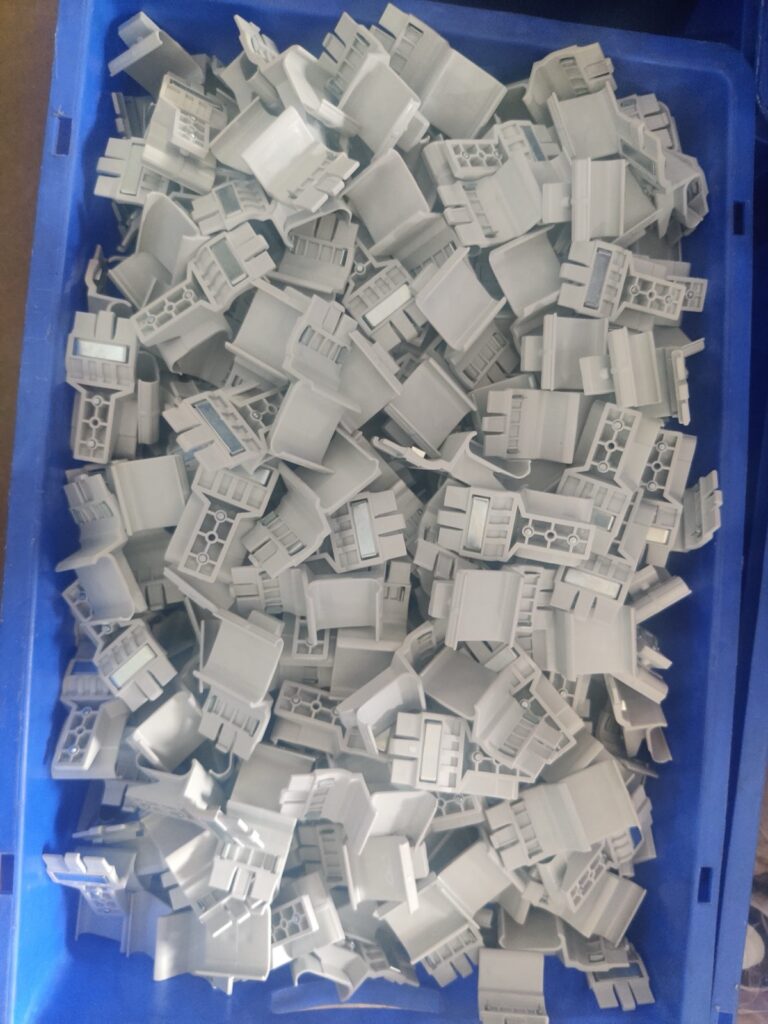

Frigate prides itself on delivering world-class CNC machining services through our team of expert Frigaters. With CNC machines primed and ready to tackle your unique manufacturing needs, we specialize in meeting tight tolerances and handling complex geometries efficiently and on time. Utilizing production-grade materials and leveraging the expertise of our reliable Frigaters, we ensure top-notch results that exceed expectations.

From laser cutting to wood routing and 3D printing, our range of CNC machines covers nearly every commercially utilized manufacturing process and application. Before commencing the manufacturing process, we conduct thorough Design for Manufacturability (DFM) assessments to ensure seamless production. We streamline the manufacturing process and optimize cost-effectiveness by defining various tolerances, rules, and common manufacturing checks.

CNC machining delivers micron precision and tight tolerances for complex geometry.

Our Clients

Our Business Verticals

Aerospace

Automotive

Healthcare

Electrical

Defense

Construction

Energy Sector

Oil & Gas

Precision Engineering for Demanding Applications

We specialize in delivering precision-engineered parts tailored to meet the most demanding specifications. With the capability to work with tight tolerances and complex geometries, we ensure that every component we produce aligns perfectly with your requirements. Whether you need standard or non-standard materials, our expert team is equipped to deliver excellence. All our parts adhere to the highest industry standards, following ISO/EN/DE guidelines, and are verified by our trusted NABL accredited testing lab partners.

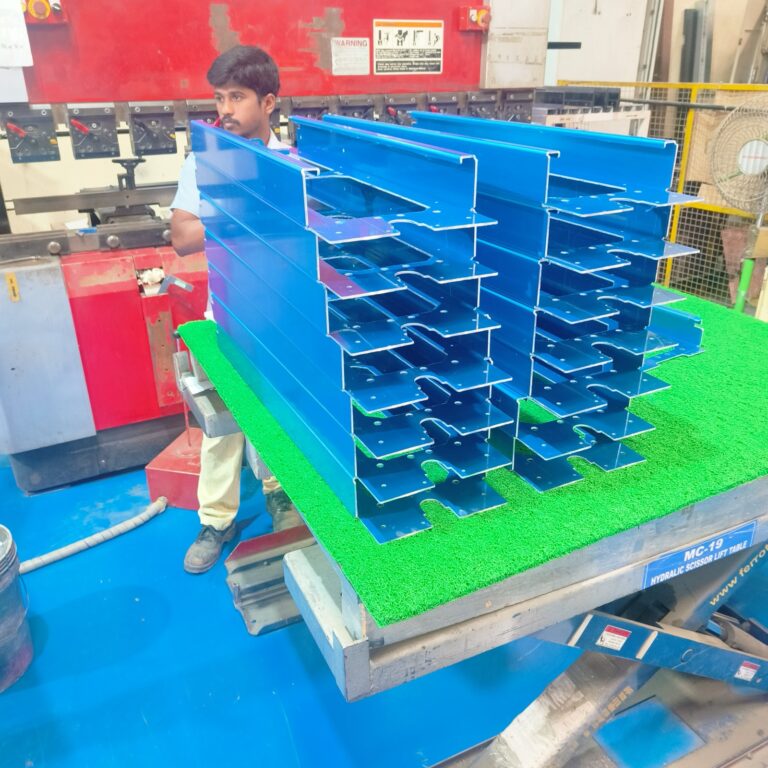

Exquisite Finishing for Impeccable Results

We understand the importance of flawless finishing to achieve impeccable results. At Frigate, we go the extra mile to ensure that every part meets your exacting standards. From cylindrical grinding to lapping and buffing, we offer a comprehensive range of surface finishing options. Additionally, we provide secondary operations such as surface treatment, heat treatment, anodization, and electroplating to further enhance the quality and durability of your components. Our specialized packaging protocols guarantee that your parts are shipped with the utmost care, ensuring they arrive safely and securely, whether by air, sea, or land freight.

Efficient Execution with Real-Time Monitoring

We leverage cutting-edge technology to streamline our manufacturing processes and enhance efficiency. With our AI platform, we provide real-time updates on the progress of each part, from material procurement to final packaging. This transparent approach ensures that you are always informed about the status of your production schedule. Additionally, we implement pre and post-machining processes to maintain the highest quality standards and meet the unique needs of our clients.

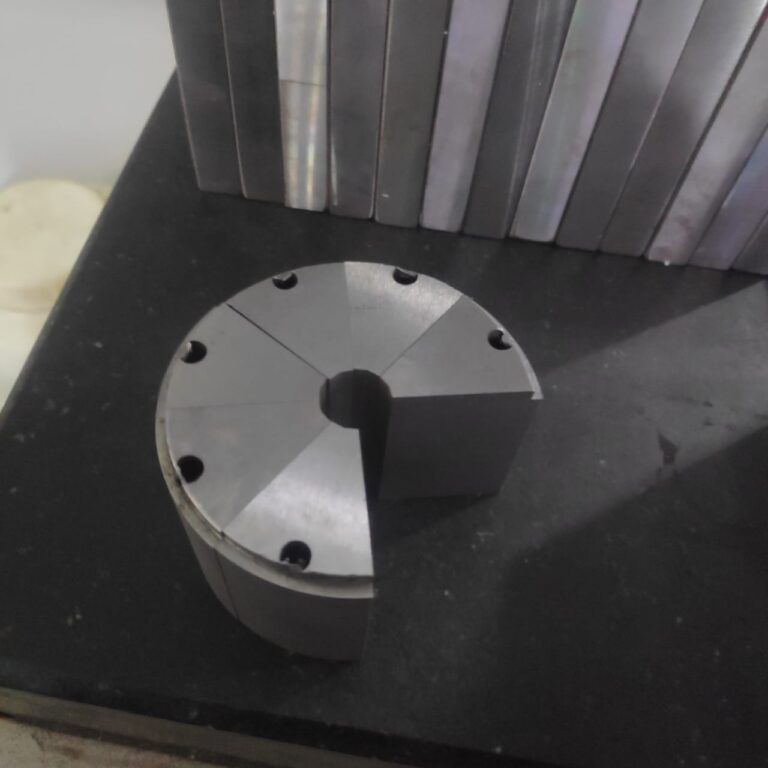

Advanced Finishing Expertise

At Frigate, we boast advanced finishing capabilities to ensure that your parts meet the highest standards of precision and quality. Our skilled technicians specialize in cylindrical, surface, and profile grinding techniques, allowing us to achieve the exact specifications required for your components. Additionally, our honing and lapping processes guarantee exceptional surface finishes, enhancing the performance and longevity of your parts. With our comprehensive range of finishing services, we can meet even the most demanding requirements with precision and efficiency.

State-of-the-Art Inspection Facilities

At Frigate, quality is our top priority, which is why we invest in state-of-the-art inspection facilities to guarantee the integrity of every part we produce. Equipped with cutting-edge technology, including Coordinate Measuring Machines (CMM), gauging systems, Non-Destructive Testing (NDT) equipment, and Counter Profiling tools, we meticulously inspect every component to ensure it meets your exact specifications. Our rigorous inspection processes enable us to maintain the highest levels of accuracy and consistency, providing you with peace of mind and confidence in the quality of our work.

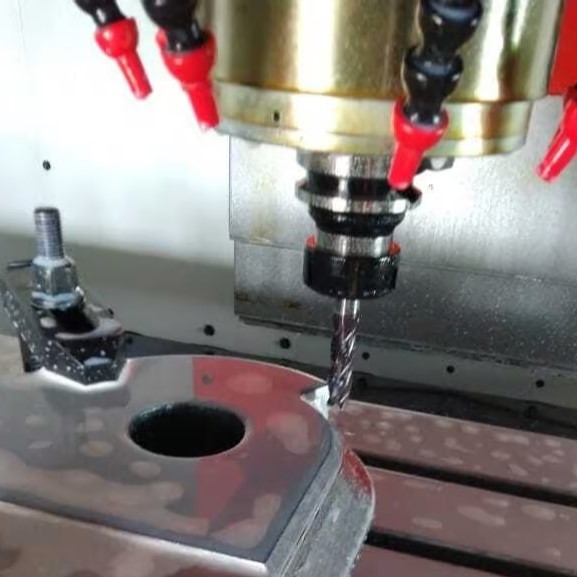

Efficient CAM Programming Solutions

At Frigate, we leverage advanced Computer-Aided Manufacturing (CAM) programming to optimize the efficiency and precision of our machining processes. Our experienced programmers utilize the latest software tools to generate efficient toolpaths and machining strategies tailored to your specific requirements. By automating and optimizing the manufacturing process, we can minimize lead times, reduce waste, and enhance overall productivity. With our CAM programming expertise, we ensure that your parts are manufactured with the highest level of accuracy and efficiency, meeting your deadlines and exceeding your expectations.

Our CNC Machining Process

Advanced algorithms optimize tool paths, minimizing tool wear, reducing cycle times, and improving surface finishes. This involves strategically planning the sequence of movements and cuts to enhance efficiency.

Modern CNC machines often utilize 5-axis or even 6-axis capabilities, allowing for complex geometries and intricate shapes. This reduces the need to reposition the part, ensuring higher accuracy and a more refined finish.

CNC machines may integrate adaptive cutting strategies, where cutting conditions (speed, feed, depth of cut) adjust dynamically based on real-time sensor feedback or cutting force monitoring. This helps prevent tool breakage and ensures optimal material removal rates.

Specialized techniques like high-speed machining enable faster spindle speeds and advanced feed rates. This increases material removal rates while maintaining fine tolerances and reducing thermal distortion.

Some CNC setups incorporate in-process measuring systems (like laser scanners or probe-based systems) to check the part’s dimensions as it’s being machined. These systems can send real-time data back to the machine, allowing for automatic adjustments during production.

CNC machines with automated tool changers enhance efficiency by switching tools automatically without operator intervention. This allows for uninterrupted multi-operation machining without downtime, improving productivity in complex jobs with several cutting tools.

CNC Machining Materials

Whether it’s taming the ferocious strength of steel or harnessing the versatility of aluminum, our CNC machining services are equipped to handle both ferrous and non-ferrous metals with precision, efficiency, and ferocious attention to detail.

Metal CNC Machining Materials

Aluminum 6061

Aluminum 5052

Aluminum 2024

Aluminum 6063

Aluminum 7050

Aluminum 7075

Aluminum MIC-6

Copper 101

Copper C110

Copper C932

Copper 260

Copper 360

Nitronic 60 (218 SS)

Stainless Steel 15-5

Stainless Steel 17-4

Stainless Steel 18-8

Stainless Steel 303

Stainless Steel 316/316L

Stainless Steel 416

Stainless Steel 410

Stainless Steel 420

Stainless Steel 440C

Steel 1018

Steel 1215

Steel 4130

Steel 4140

Steel 4140PH

Steel 4340

A2 Tool Steel

O1 Tool Steel

Titanium (Grade 2)

Titanium (Grade 5)

Zinc Alloy

Plastic CNC Machining Materials

High-strength engineering plastic used for many commercial products.

A clear glass-like plastic. Reasonable wear and tear properties. Great for outdoor use.

Acetal

Delrin 150

Delrin 100

Resin with good moisture resistance, high wear resistance, and low friction.

Garolite G10 (FR4)

Garolite G10 (non-FR)

Garolite G11 (FR5)

Constructed of an epoxy resin with fiberglass fabric reinforcement, also called epoxy-grade industrial laminate and phenolic, this material offers high strength and low moisture absorption.

High-density polyethylene is a moisture and chemical-resistant plastic with good impact strength. The material is outstanding for outdoor applications as well as watertight containers or seals.

Offers increased mechanical strength, rigidity, good stability under heat and/or chemical resistance.

With almost twice the tensile strength of ABS, polycarbonate has superior mechanical and structural properties. It is widely used in automotive, aerospace, and other applications that require durability and stability.

PEEK

PEEK (USP Class VI TECAPEEK)

PEEK GF30

Offering excellent tensile strength, PEEK is often used as a lightweight substitute for metal parts in high-temperature, high-stress applications. PEEK resists chemicals, wear, and moisture.

Has excellent electrical properties and little or no moisture absorption. It carries light loads for a long period in widely varying temperatures. It can be machined into parts requiring chemical or corrosion resistance.

This material surpasses most plastics when it comes to chemical resistance and performance in extreme temperatures. It resists most solvents and is an excellent electrical insulator.

Ultra-high molecular weight polyethylene. A general-purpose material. It offers a unique combination of wear and corrosion resistance, low surface friction, high impact strength, high chemical resistance, and does not absorb moisture.

Polyvinyl chloride (Type 1) is a highly chemical-resistant synthetic plastic, PVC is commonly in environments exposed to liquids or requires electrical insulation.

ULTEM 1000

ULTEM 2300

ULTEM (Polyetherimide) is a stiff, robust, performance-grade thermoplastic that can operate continuously in high-temperature environments (up to 340°F). It has one of the highest dielectric strengths of commercially available thermoplastics, making it an excellent electric insulator. Since ULTEM is also resistant to chemicals, easily cleaned, and does not absorb moisture, it is often used for medical applications.

CNC Machining Finishes

The finish option with the quickest turnaround. Machined parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. CNC machining surface finish is comparable to 125 uin Ra finish.

The part surface is left with a smooth, matte appearance.

This is a batch-based process that tumbles vibrating media to remove sharp edges and burrs on CNC parts. Tumbling can remove machine marks on exterior surfaces. Parts over 8” may require a manual review.

Type II (MIL-A-8625, Type II) creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and are usually associated with aluminum. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

A surface finish for titanium per AMS-2488 Type 2 specification. Also called Tiodize, this finish increases fatigue strength and the wear resistance of a part. Titanium anodized parts are common in aerospace and medical device manufacturing. Non-pigmented titanium anodize finishes will dull shine.

A hard coat anodize process that embeds PTFE to create a self-lubricating, dry contact surface with Type 3 hard coat’s protective properties. This finish can be used on aluminum alloys or titanium and increases the service life of the product. This finish conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed).

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint. Can leave surface yellow/gold. Adds very little thickness, about 0.00001”-0.00004”. Chem film will conform to MIL-DTL-5541, TYPE I/II.

Improves corrosion resistance for 200 and 300 series and precipitation hardened corrosion-resistant steels. Thickness is negligible, about 0.0000001”. Conforms to ASTM A967, AMS-QQ-P-35, MIL-STD-171, ASTM A380, or AMS 2700.

This process is where powdered paint is sprayed onto a part and baked in an oven. This creates a strong, wear- and corrosion-resistant, more durable layer than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

An electrochemical process cleans steel parts to reduce corrosion and improve appearance, by making the metal brighter. Removes about 0.0001”-0.0025” of the metal. Conforms to ASTM B912-02.

Provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. The finished part will be brighter. Thickness starts at .0001”. Conforms to MIL-C-26074.

Silver offers high solderability and electrical conductivity but is susceptible to tarnish. Conforms to AMS QQ-S-365D. Thickness is about 0.00002” - 0.0003.”

Gold Plating provides good corrosion and tarnish resistance with excellent solderability. Default application specification is MIL-G-45204 and ASTM B488, CLASS 00, 0, OR 1. Thickness is about 0.00002" - 0.00005."

Provides uniform zinc coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. Conforms to ASTM B633-15.

Frigate Approach

Achieve Production Goals with Frigate's CNC Machining

Transform your manufacturing processes with Frigate’s industry-leading CNC machining expertise. Leveraging cutting-edge technology and a team of dedicated professionals, we deliver unmatched precision, efficiency, and quality control. Contact us today to discuss your project requirements and unlock the full potential of your business.

Compliance for CNC Machining Services

We prioritize strict compliance with industry standards and regulations to ensure the highest quality and precision in our CNC machining services. Our commitment to compliance spans multiple areas, including safety, environmental impact, and material handling, all to meet the specific needs of our clients while adhering to the latest advancements in manufacturing practices.

Key Compliance Areas

Adherence to global quality standards, ensuring consistency, precision, and traceability throughout the machining process.

Meeting rigorous aerospace industry requirements for quality assurance and risk management.

Ensuring all materials and components are free from hazardous substances to meet environmental safety standards.

Safeguarding customer information in line with GDPR for privacy and security.

Complying with European Union regulations for manufacturing safety, health, and environmental protection requirements.

Commitment to sustainable practices and minimizing environmental impact in machining operations.

Tolerance for CNC Machining Services

Fine tolerances for precise measurements in small components.

Includes features like flatness, parallelism, and perpendicularity.

Dependent on machining method and tool selection.

Precision achieved using reaming or honing for tight fits.

Depends on the type of thread (e.g., ISO, NPT).

Ensures proper alignment of holes and features in assembled parts.

Critical for parts requiring rotating or moving components.

Ensures parts are balanced and rotate smoothly in their assemblies.

Quality Testing Standards for CNC Machining Services

To measure the roundness of cylindrical features, ensuring they meet tolerance requirements.

To check internal surfaces for flatness, critical for sealing and assembly purposes.

To identify burrs or sharp edges that may affect assembly or safety.

To ensure that complex profiles (e.g., contours, curves) conform to design specifications.

To verify that the surface hardness depth meets the required specifications for wear resistance.

To test the material's resistance to tension, ensuring it meets required mechanical properties.

To assess the toughness of materials, particularly important for high-stress applications.

To test the ability of parts to withstand cyclic loading without failure.

To measure deflection under load, ensuring parts maintain structural integrity under operating conditions.

To ensure complex shapes, such as curves or non-linear features, meet strict design requirements.

To evaluate the effects of heat treatment on material properties and ensure desired characteristics like strength and toughness.

To verify grain structure, inclusions, and material consistency, ensuring the part meets performance requirements.

To measure internal stresses that could lead to deformation or failure during or after machining.

To check the topography and texture of the surface, ensuring it meets the required specifications for function or aesthetics.

To measure hardness across different depths, ensuring a consistent surface hardness profile for wear resistance.

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

Having Doubts? Our FAQ

Check all our Frequently Asked Question

For milling Frigate supports parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm) & for Lathe machining, we support parts up to 62” (1,575 mm) length and 32” (813 mm) diameter.

In VMC, we have 600mm*600mm*600mm table capacity when it comes to 5 axis and up to 3 meters when it comes to 3 axis machining & up to 1 meter when it comes to 4 axis.

Tolerances as per ISO 2768 unless otherwise specified. Maximum tolerance for plastics and composites will be +/- 0.010”.

The standard finish is as-machined: 125 Ra or better. However, Frigate would be happy to support requests of any specific surface finish. Please let us know what type of surface finish would meet your requirements when asking for our quote.

Frigate can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review.

All kinds of metals & non-metals, woods, acrylics, foams, Delrin, nylon, PTFE(Teflon) and other thermoplastic materials.

Manufacturing Capability/Capacity

Ferrous casting

Mold size(max): 1m X 1m

Weight Range: 1 KG ~ 30 KGS

Mold size(max): 1.5m X 1.5m

Weight Range: 30 KG ~ 150 KGS

Mold size(max): 3m X 3m

Weight Range: 100 KG ~ 1000 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.250 KG ~ 20 KGS

Mold size(max): 500 MM X 500 MM

Weight Range: 0.100 KG X 20 KGS

Non-ferrous casting

Capacity: 5000 MT/a

Range of weight: 100 gm to 20 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Mold size(max): 1 M X 1 M

Weight Range: 0.5 KG X 50 KGS

Forging

Capacity: 20,000 Tons per Annum

Range of weight: 300 KG to 1 Ton

Hammering: 5 Ton

Range of weight: 0.2 KG to 200 KGS

Hammering: 1600 Ton Hydraulic press

Ring size: 350 MM OD to 3000 MM OD

Range of weight: 15 KGS to 3200 KGS

Materials

Carbon Steel, Stainless Steel (AUSTENITE), Alloy Steel, Stainless Steel (MARTENSITE), etc.

Machining

1 to 1000 MM

1 to 1000 MM

1 to 1000 MM

Materials

Steel, Aluminum, Brass, Copper, Titanium, Nickel Alloys, Tungsten Carbide, etc.

Plastics

Materials

1250 X 1250 MM

Within 10 microns

Engineering Plastics, Polyethylene, Polypropylene, Polyvinyl chloride, Polyethylene terephthalate, Bioplastics, etc.

Rubber

Materials

Natural rubber, Styrene-Butadiene Rubber, Nitrile Butadiene Rubber, Silicone Rubber, Fluorocarbon Rubber, Recycled Rubber, etc.

Heavy Fabrication

24000 MT/a

Materials

CS / MS, Alloy steel, Stainless Steel, etc.

Sheet Metal Fabrication

0.8 to 25 mm

Materials

Mild Steel, Stainless Steel, Aluminum, Brass, Copper, etc.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Global Sales Office

818, Preakness lane, Coppell, Texas, USA – 75019

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- Texas, USA