- Precision Power

Transformers for Control Panels & Switchgear

Frigate transformers ensure precise voltage regulation and galvanic isolation for stable control signal performance in high-interference industrial environments.

- Timely Dispatch

- Cost Efficiency

- Pre-Production Samples

- Voltage Stability

Ensures accurate low-voltage supply for PLCs and relays with minimal deviation during load changes and switching transients.

- Electrical Isolation

Prevents interference between control and power circuits using high-dielectric insulation and safe creepage/clearance design.

- Thermal Reliability

Operates efficiently under heat stress with low-loss cores, Class F/H insulation, and improved heat dissipation design.

- Global Trust

Our Clients

Preferred by OEMs and system designers for transformer sourcing

- Engineered Range

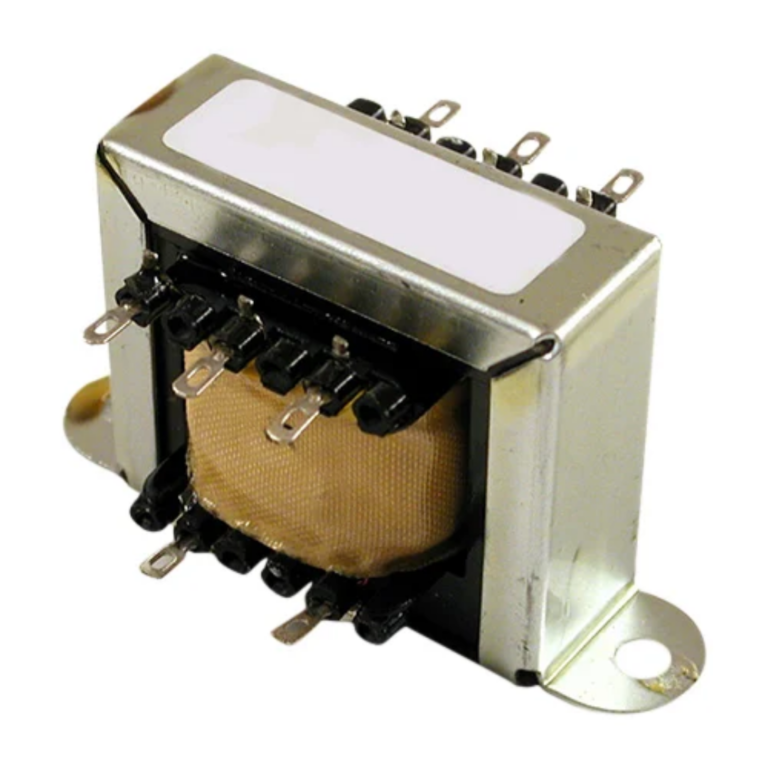

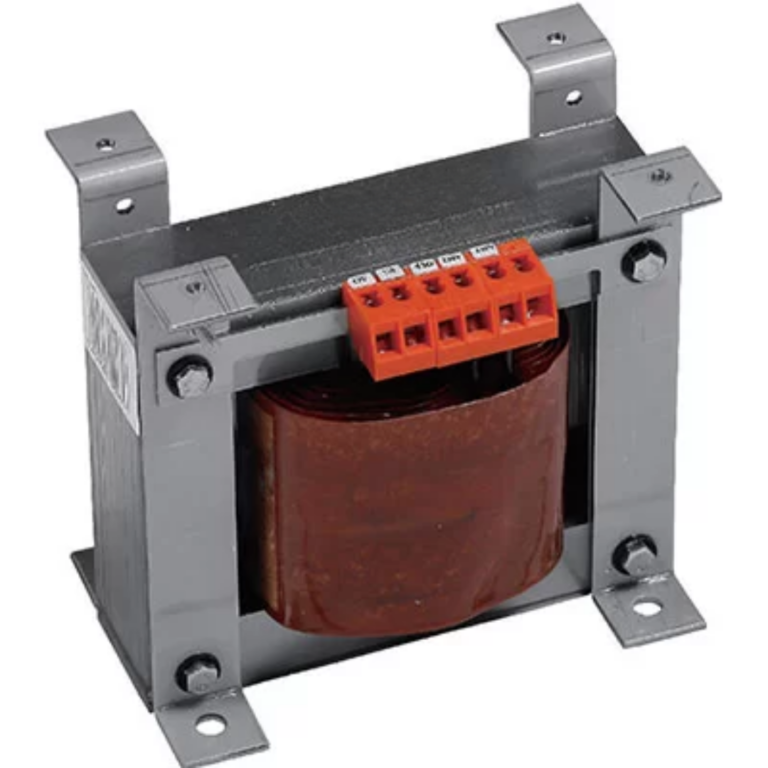

Our Products

Browse our transformer lineup built to support diverse voltage, insulation, and mounting needs across industries.

- Products Delivered

Feedback from Transformer Clients

Hear how procurement teams and engineering leads rate our transformer reliability, customization depth, and production consistency.

“Been using their dry-type units for the last 6 months. Build quality is solid. No overheating, no complaints.”

“Very smooth sourcing. Cords work fine. Packaging was neat also!”

“High frequency noise dropped significantly. We tested many suppliers but this part was very stable. Frigate team answered all specs questions quickly.”

“The units were delivered well-packed. Slight delay on customs but Frigate handled all communication quickly. Output stability is very reliable. Good value for money.”

“ Fire rating passed inspection, no trouble. Cables are flexible enough for tight runs. Cheers to Frigate.”

“We sourced this for an automotive application... Fitment exact. Thermal performance very clean. Price also reasonable. No issue so far! ”

“Cable is very tough... no crack during installation, even in outdoor condition. Shipment take 3 weeks, but product was good. We Source again sure.”

“ Frigate sent us samples Fast. The lamination is smooth, no burrs. Our assembly team had zero fitting issues.”

“ Delivery time was okay. The plastic molding finish on the plug could improve. But it works well. Good for bulk orders.”

“ We installed the busbars into our LV switchboards. Stable output readings and connection layout was compact. Better than our last supplier.”

- Real Impact

Words from Clients

See how global OEMs and sourcing heads describe their experience with our scalable execution.

“Quick turnaround and solid quality.”

“The instant quote tool saved us time, and the parts were spot-on. Highly recommend Frigate!”

“I would strongly recommend Frigate to anyone who wants to do Rapid Prototyping, and take their ideas to manufacturing. One firm doing all kinds of Product Development!”

“Great service, fair price, and the parts worked perfectly in our assembly.”

“Top-notch machining and fast shipping. Very satisfied with the results.”

“The next disruption is happening in Prototyping & Manufacturing on-demand and Frigate is leading the way! I personally believe the Frigate's way of IIOT enabled cloud platform with Al.”

“Frigate delivered high-quality parts at a competitive price. The instant quote tool is a huge plus for us!”

“We appreciate the precision and quality of the machined components in the recent delivery—they meet our specifications perfectly and demonstrate Frigate’s capability for excellent workmanship.”

“Flawless execution from quote to delivery.”

“I am absolutely happy to work with supplier like Frigate who were quite proactive & result oriented . Frigate has high willingness team who has strong know how & their passion towards the products & process were absolutely thrilling.”

“The precision on these parts is impressive, and they arrived ahead of schedule. Frigate’s process really stands out!”

“Parts were exactly as spec’d, and the instant quote made budgeting a breeze.”

“Good value for the money.”

“The finish was perfect, and the team was easy to work with.”

“Working with Frigate has been great. Their proactive, results-driven approach and expertise shine through in every project. It's been a pleasure collaborating with them.”

"We are highly satisfied with the timely delivery and quality of the MIG Welding Cable from Frigate. Their attention to detail, secure packaging, and quick responsiveness stood out. We confidently recommend Frigate Engineering Services Pvt. Ltd. as a reliable manufacturing partner."

- Grid Flexibility

Critical Use Cases in Control and Protection Circuitry

Transformers integrated within control panels and switchgear assemblies perform essential electrical functions, including galvanic isolation, step-down voltage conversion, transient suppression, and low-noise power delivery.

Programmable Logic Control and Actuation Systems

Delivers regulated secondary voltage to drive PLC input/output modules, contactors, and field interface devices with high load stability.

Protective Relay and Auxiliary Trip Circuits

Provides isolated control power to relays and breaker tripping units, ensuring signal integrity during high-voltage switching and fault conditions.

- Grid Flexibility

Multi-Voltage Compatibility

Frigate designs control transformers to support a wide range of global voltage inputs through multi-tap primary windings from 208 V to 480 V.

Frequency Agnostic Operation

Magnetic cores are selected for stable performance at both 50 Hz and 60 Hz, ensuring consistent efficiency without frequency-specific tuning.

Harmonic Tolerance

Transformers are engineered with low core loss and high linearity to handle harmonic distortion from non-linear loads without excessive heating.

Full-Spectrum Transformer Solutions

Engineered for high-reliability environments, our Control Panels & Switchgear transformers deliver precise voltage regulation, low leakage current, and superior EMI suppression.

- Power Assurance

Performance and Safety Testing for Control Systems

Frigate engineers transformers for control panels and switchgear with precise voltage regulation, high dielectric strength, and thermal resilience in demanding electrical networks. Advanced testing protocols validate performance, safety, and lifecycle stability in mission-critical power distribution and control applications.

- Our Blogs

Insights from Transformer Manufacturing Experts

Read technical articles on transformer integration, compliance standards and sourcing strategies across industry-specific use cases.

Frigate designs its control transformers with low leakage reactance and optimized core geometry to maintain constant secondary voltage under varying loads. Load regulation is tightly controlled to prevent signal disruption in logic circuits. Laminated silicon steel cores with precise stacking reduce magnetic hysteresis. This ensures the transformer response remains linear even under sudden switching operations.

Frigate employs sectionalized windings and electrostatic shields between primary and secondary coils to block high-frequency interference. This construction reduces capacitive coupling and mitigates EMI propagation across circuits. Twisted pair winding for low-voltage outputs is also used to suppress radiated noise. The result is improved signal integrity in high-density control systems.

Frigate uses Class H insulation systems with vacuum pressure impregnation (VPI) to improve thermal endurance of windings. Heat is evenly distributed across the coil stack using thermal conduction paths and resin-soaked windings. These designs prevent local hotspots during high-duty operation cycles. Insulation aging is minimized even in enclosed, poorly ventilated switchgear compartments.

Frigate specifies copper windings with reinforced mechanical bracing to withstand short-circuit forces. Core clamps and terminal blocks are secured to resist axial displacement during fault events. Designs are tested per IEC 60076-5 for thermal and mechanical withstand. This ensures reliable operation during downstream breaker or relay failures.

Multi-tap primary windings are integrated to allow direct operation from 208 V, 240 V, 415 V, or 480 V supplies. Frigate designs ensure uniform flux density across taps to avoid efficiency loss. Dual-frequency (50/60 Hz) support is achieved using low-loss, frequency-tolerant core materials. This allows seamless deployment without hardware modification.

We'd love to Manufacture for you!

Submit the form below and our representative will be in touch shortly.

LOCATIONS

Registered Office

10-A, First Floor, V.V Complex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, India.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti, Coimbatore-641035, Tamil Nadu, India. ㅤ

Other Locations

- Bhilai

- Chennai

- USA

- Germany