Extrusion Services

Frigate excels in the precision extrusion of thermoplastic and thermoset materials. Our advanced technology ensures consistent accuracy and high-performance characteristics.

Holen Sie Sich Ihr Angebot Jetzt

- Instant Zitat

- Auf-Zeit Lieferung

- Erschwingliche Kosten

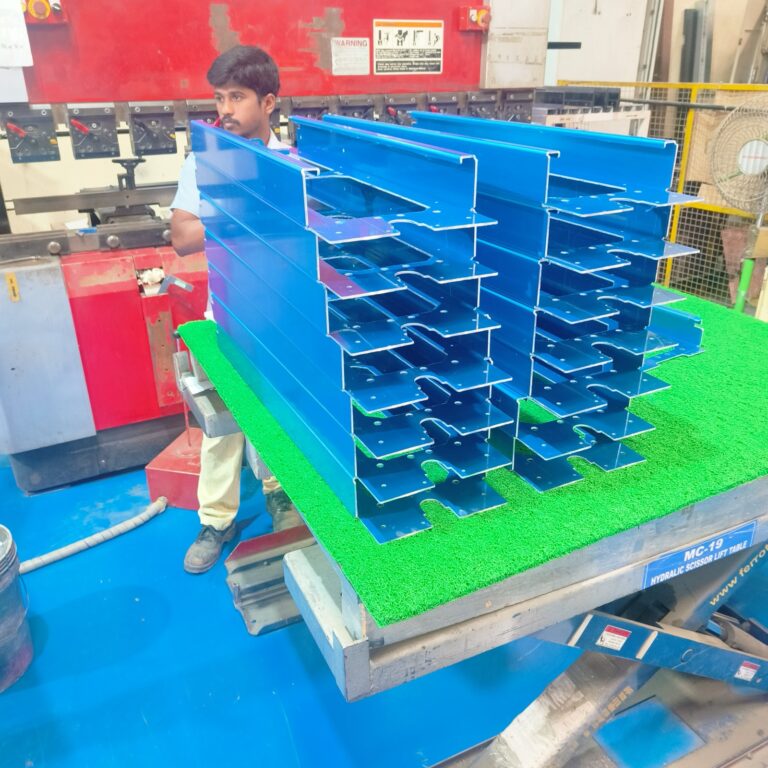

Custom Extrusions Tailored to Your Needs

Custom extrusions are tailored to meet specific user requirements. This process involves creating precise shapes for various applications across industries. Frigate is a leading provider of custom extrusions, offering expert guidance and personalized services.

Our team ensures your designs are reusable and optimized for their intended environments. With decades of experience, Frigate meets all your custom extrusion needs with exceptional care and quality.

Minimize Lead Time Challenges

Utilizing a streamlined production schedule helps optimize workflow and minimize delays. This ensures efficient resource use and better alignment with customer timelines.

Implementing effective inventory management practices ensures the availability of essential materials. This reduces lead times by streamlining the procurement process and mitigating material shortages.

Regular updates on production status and potential delays keep customers informed. This proactive approach enhances transparency and allows for better planning on both sides.

Streamline Cost Management Processes

Providing clear and detailed cost breakdowns allows customers to understand pricing structures. This helps them make informed decisions and manage budgets effectively.

Collaborating on design to identify cost-effective alternatives without compromising quality can lead to significant savings. This approach enhances the overall efficiency of the extrusion process.

Implementing lean manufacturing principles reduces waste and enhances efficiency. This continuous improvement approach can lead to lower operational costs, benefiting customers.

Optimize Technical Assistance and Interaction

Offering specialized support throughout the design and production phases ensures customer needs are met accurately. This dedicated approach minimizes misunderstandings and production errors.

Providing consistent communication on project progress keeps customers informed. This allows for timely adjustments and fosters a collaborative relationship.

Delivering detailed documentation on processes and specifications ensures clarity. This comprehensive approach helps customers understand all aspects of the extrusion process, enhancing confidence in the final product.

Extrusion Materials

The extrusion process is a vital method for manufacturing complex shapes. It forces the material through a die to achieve precise dimensions and properties.

Aluminum alloys are widely used in extrusion due to their lightweight and high strength-to-weight ratio. Common alloys, such as 6061 and 6063, offer excellent corrosion resistance and good machinability, making them suitable for various applications, including automotive and construction.

Copper alloys, including brass and bronze, are also suitable for extrusion. They provide good electrical and thermal conductivity. Applications often include electrical components and plumbing fixtures, where conductive properties are essential.

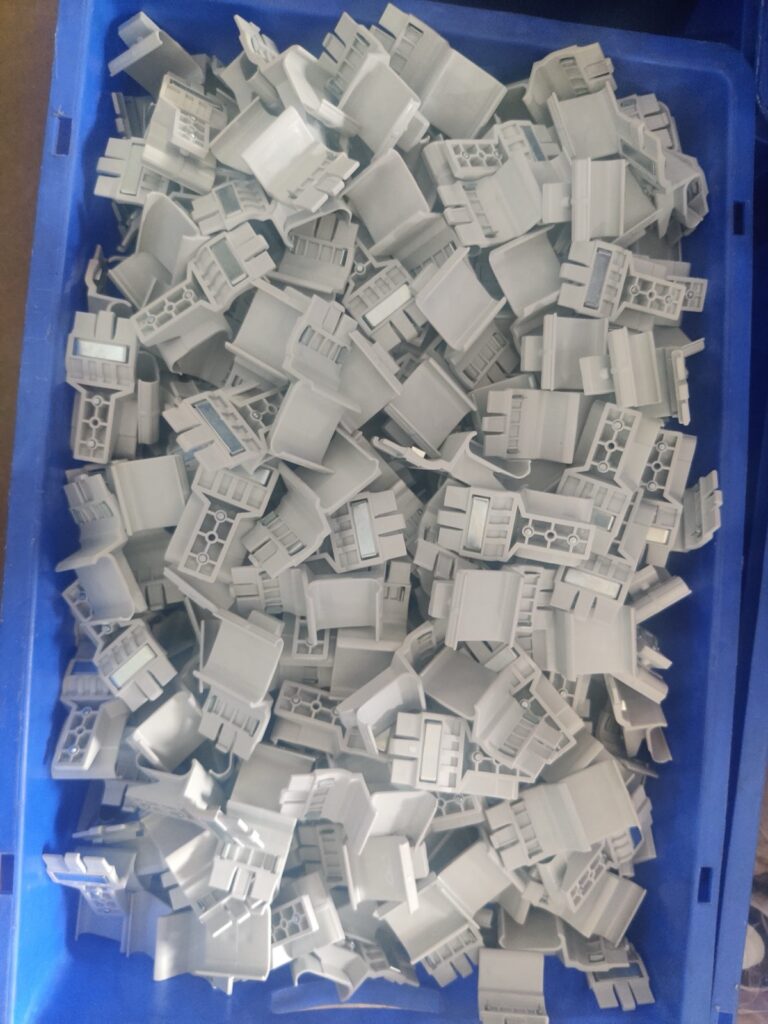

Thermoplastics, such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), are frequently extruded into various shapes. These materials are known for their versatility and durability, making them ideal for packaging, construction, and automotive applications.

Carbon and stainless steel can be extruded to produce components that require high strength and durability. Steel extrusion is commonly used in construction, automotive, and heavy machinery applications, where structural integrity is critical.

Magnesium alloys offer a lightweight alternative for high-strength and low-density applications. Their use in aerospace and automotive industries is increasing, as they contribute to weight reduction without compromising performance.

Zinc alloys are also used in extrusion, particularly for applications that require corrosion resistance. They are often used in die-casting processes but can also be extruded for specific components.

Composite materials can be extruded to achieve tailored properties by combining different substrates. These materials can enhance performance, offering benefits such as increased strength, reduced weight, and improved thermal resistance.

Certain applications may require specialty alloys, such as titanium or high-strength aluminum alloys. Depending on the specific application requirements, these materials are selected for their unique properties, such as high-temperature resistance or enhanced mechanical strength.

Enhancing Efficiency in Post-Extrusion Processing

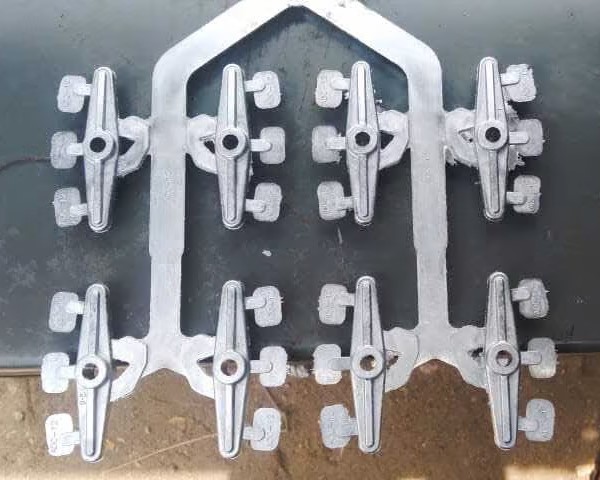

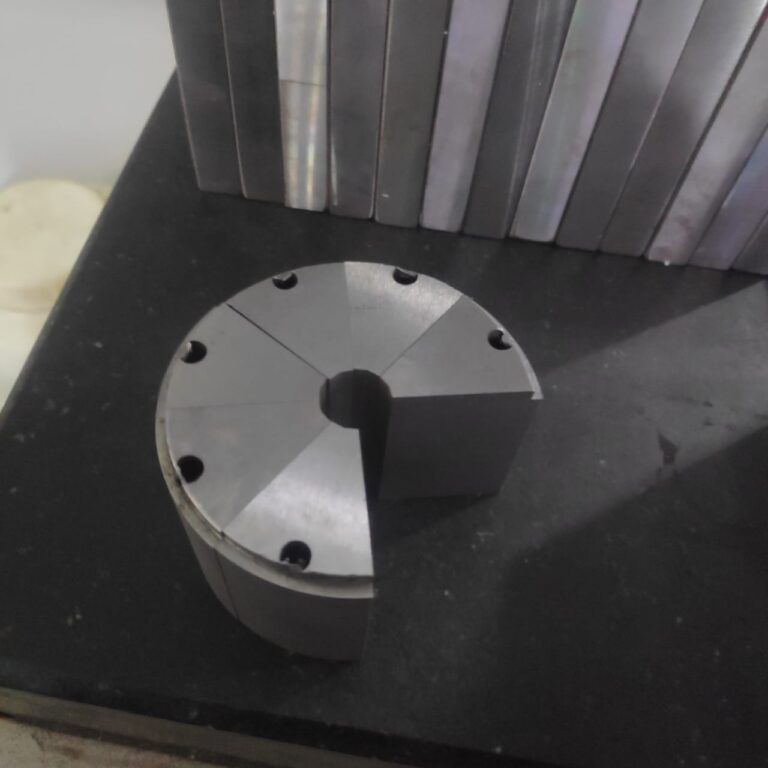

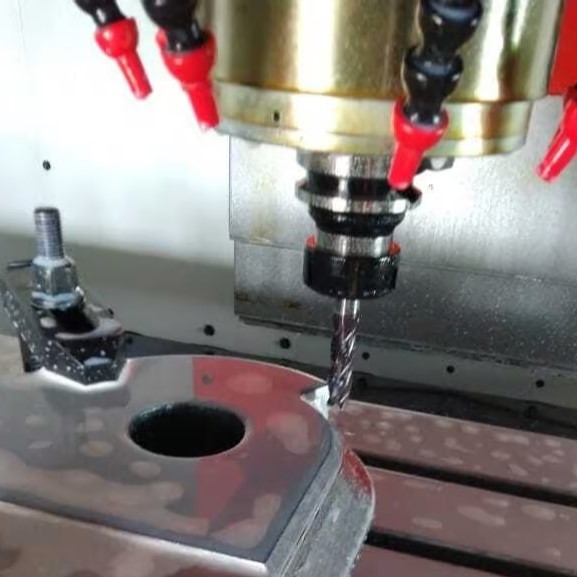

After extrusion, additional processing steps are often required to meet final product specifications. These steps may include machining, finishing, and assembly, which enhance functionality and appearance. Machining removes material to achieve precise dimensions, while finishing processes, such as anodizing and polishing, improve surface properties and visual appeal.

Coordinating these processes can be complex and may lead to increased costs and longer timelines. Effective communication between extrusion and post-processing teams is essential for minimizing delays. Fregatte supports the management of these processes, optimizing machining, finishing, and assembly to efficiently meet specific customer requirements.

- Echte Wirkung

Wörter von Kunden

Sehen Sie, wie Globale OEMs und sourcing-Köpfe beschreiben Sie Ihre Erfahrung mit unseren skalierbaren Ausführung.

"Schnelle Bearbeitung und solide Qualität."

“Der instant quote tool hat uns gerettet-Zeit, und die Teile waren auf den Punkt. Empfehlen Fregatte!"

“Ich würde dringend empfehlen Fregatte wer will zu tun, Rapid Prototyping, und Ihre Ideen in die Fertigung. Eine Firma tun alle Arten von Produkt Entwicklung!"

"Great service, fair Preise, und die Teile perfekt gearbeitet, in unserer Versammlung."

“Top-notch Bearbeitung und schnelle Lieferung. Mit den Ergebnissen sehr zufrieden."

“Die nächste Störung geschieht in Prototyping & Manufacturing on-demand-und Fregatte den Weg! Ich persönlich glaube, daß die Fregatte die Möglichkeit, IIOT-fähigen cloud-Plattform mit Al."

“Fregatte geliefert hochwertige Teile zu einem wettbewerbsfähigen Preis. Instant quote tool ist ein großes plus für uns!"

"Wir schätzen die Präzision und Qualität der bearbeiteten Komponenten in der jüngsten Lieferung—Sie erfüllen unsere Vorgaben perfekt und zeigen Fregatte, die diese Fähigkeit für die hervorragende Verarbeitung."

"Reibungslose Abwicklung vom Angebot bis zur Lieferung."

“Ich bin absolut glücklich zu arbeiten mit Lieferanten wie Fregatte, die waren sehr proaktiv & ergebnisorientiert . Fregatte hat eine hohe Bereitschaft team, die hat starke know how und Ihre Leidenschaft zum Produkt & Prozess waren absolut mitreißend."

“Die Präzision, die auf diese Teile ist beeindruckend, und Sie kamen vor dem Zeitplan. Fregatte Prozess wirklich herausragend!"

"Die Teile waren genau so, wie geskilled, und die instant-Zitat aus der Budgetierung ein Kinderspiel."

"Good value for the money."

"Das finish war perfekt, und das team war einfach, mit zu arbeiten."

“Arbeiten mit der Fregatte war großartig. Ihre proaktive, ergebnisorientierte Ansatz und know-how durchleuchten, in jedem Projekt. Es war ein Vergnügen, die Zusammenarbeit mit Ihnen."

"Wir sind sehr zufrieden mit die rechtzeitige Lieferung und die Qualität des MIG-Schweißens-Kabel von der Fregatte. Ihre Aufmerksamkeit zum detail, sichere Verpackung und schnelle Reaktionsfähigkeit Stand out. Wir getrost empfehlen Fregatte Engineering Services Pvt. Ltd. als zuverlässiger partner für die Herstellung."

Having Doubts? Our FAQ

Check all our Frequently Asked Question

Frigate employs precise die design and advanced extrusion techniques to pflegen tight tolerances. This minimizes variation in dimensions, ensuring that each profile meets customer specifications consistently.

Frigate implements rigorous quality control processes during extrusion. This includes real-time monitoring of temperature, pressure, and material flow, along with thorough inspections to identify and rectify defects early in production.

Frigate coordinates closely with customers to streamline post-extrusion processes like machining and finishing. By managing these steps effectively, Frigate helps reduce lead times and ensure that final products meet specific functional and aesthetic requirements.

Frigate offers expertise in selecting appropriate aluminum alloys based on application needs. For example, 6061 alloy is ideal for structural applications, while 6063 is better suited for architectural features due to its excellent finish and workability.

Fregatte maintains transparent communication about material costs and potential changes during the extrusion process. By providing detailed cost estimates and alternatives, Frigate helps customers manage budgets effectively while ensuring high-quality outcomes.

Herstellungs-Fähigkeit/Kapazität

Eisen casting

Mold Größe(max): 1m X 1m

Gewicht: 1 KG ~ 30 KG

Mold Größe(max): 1,5 m X 1,5 m

Gewicht: 30 KG ~ 150 KG

Mold Größe(max): 3m X 3m

Gewicht: 100 KG ~ 1000 KG

Mold Größe(max): 500 MM X 500 MM

Gewicht: 0.250 KG ~ 20 KG

Mold Größe(max): 500 MM X 500 MM

Gewicht: 0.100 KG X 20 KG

Nichteisen-Guss

Kapazität: 5000 MT/a

Palette von Gewicht: 100 G bis 20 KG

Mold Größe(max): 1 M X 1 M

Gewicht: 0,5 KG X 50 KG

Mold Größe(max): 1 M X 1 M

Gewicht: 0,5 KG X 50 KG

Schmieden

Kapazität: 20,000 Tonnen pro Jahr

Palette von Gewicht: 300 KG bis zu 1 Tonne

Hämmern: 5 Tonne

Palette von Gewicht: 0,2 KG-200 KG

Hämmern: 1600-Tonnen-Hydraulischen Presse

Ring-Größe: 350 MM OD bis 3000 MM OD

Palette von Gewicht: 15 KG bis 3200 KG

Materialien

Carbon Stahl, Edelstahl (AUSTENIT), Legierter Stahl, Rostfreier Stahl (MARTENSIT), etc.

Bearbeitung

1 bis 1000 MM

1 bis 1000 MM

1 bis 1000 MM

Materialien

Stahl, Aluminium, Messing, Kupfer, Titan, Nickel-Legierungen, Hartmetall, etc.

Kunststoff

Materialien

1250 X 1250 MM

Innerhalb von 10 Mikron

Technische Kunststoffe, Polyethylen, Polypropylen, Polyvinylchlorid, Polyethylenterephthalat, Biokunststoffe, etc.

Gummi

Materialien

Natürliche Gummi, Styrol-Butadien-Kautschuk, Nitril-Butadien-Kautschuk, Silikon-Kautschuk, Fluor-Kohlenstoff-Gummi, Recyceltem Gummi, etc.

Schwere Fertigung

24000 MT/a

Materialien

CS / MS, Alloy steel, Stainless Steel, etc.

Sheet Metal Fabrication

0,8-25 mm

Materialien

Mild Stahl, Edelstahl, Aluminium, Messing, Kupfer, etc.

Wir freuen uns auf Herstellung für Sie!

Füllen Sie das untenstehende Formular und unser Vertreter wird Sie in Kürze.

LOCATIONS

Sitz

10-A, First Floor, V. V Komplex, Prakash Nagar, Thiruverumbur, Trichy-620013, Tamil Nadu, Indien.

Operations Office

9/1, Poonthottam Nagar, Ramanandha Nagar, Saravanampatti Coimbatore-641035, Tamil Nadu, Indien. ㅤ

Weitere Standorte

- Bhilai

- Chennai

- Texas, USA